Search found 28 matches

- by christhewelder75

- Tue Dec 27, 2016 2:31 pm

- Forum: Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- Topic: 1/4" aluminum weld

- Replies: 12

- Views: 1095

Re: 1/4" aluminum weld

4043 rod is the problem. Found it out doing test welds for a project in the shop with aluminum gmaw switched to 5356 and it held waaay better. Give that a go. I'm sure 4043 welded on both sides would hold but I don't think it's made for that kind of force application. I may be wrong but that's my ex...

- by christhewelder75

- Mon Dec 26, 2016 8:54 pm

- Forum: Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- Topic: Stainless handrails without traditional finishing tool

- Replies: 2

- Views: 488

Re: Stainless handrails without traditional finishing tool

Well not quite done we have till the end of the month. Have 4 floor opening rails still to fit and weld and finish. Oh and install. I don't think it's gonna hit the deadline I'll do my best but times not on our side

- by christhewelder75

- Mon Dec 26, 2016 12:41 pm

- Forum: Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- Topic: Stainless handrails without traditional finishing tool

- Replies: 2

- Views: 488

Stainless handrails without traditional finishing tool

Hey guys. So the shop decided to bid on a job for stainless hand rails and got it. Then someone either ordered the wrong material by accident or on purpose to save money (38mm tube with 1.6mm wall thickness vs the proper like 1 1/4" schedule 40) We built the rails to the prints installed them t...

- by christhewelder75

- Fri Oct 07, 2016 10:27 pm

- Forum: Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- Topic: I love my job, I love my job, I love my job....

- Replies: 6

- Views: 1002

Re: I love my job, I love my job, I love my job....

Think it was about -3 Celsius with the wind gusting to 33km. .. not that bad really but still a pain trying to walk on smooth aluminum with a layer of snow

- by christhewelder75

- Fri Oct 07, 2016 2:24 pm

- Forum: Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- Topic: I love my job, I love my job, I love my job....

- Replies: 6

- Views: 1002

I love my job, I love my job, I love my job....

Today at work. ..https://imgur.com/gallery/h5Ute

Good old alberta weather.... Oct 7 and it's blowing snow out

Good old alberta weather.... Oct 7 and it's blowing snow out

- by christhewelder75

- Wed Aug 24, 2016 10:17 pm

- Forum: Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- Topic: Starting a new job

- Replies: 19

- Views: 1572

Re: Starting a new job

I honestly have no idea how common the welded panels are on roofs. This is the first job I've had in the field. (Usually in a shop doing structural stuff) Sounds like my boss has done a number of them in various locations across Canada. Today I started on the 22ga corrugated stuff welding down the l...

- by christhewelder75

- Tue Aug 23, 2016 6:59 pm

- Forum: Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- Topic: 1g cwb test angle for root

- Replies: 2

- Views: 2057

Re: 1g cwb test angle for root

It's 2 roots and a face bend on all cwb GF tests now. U want ur electrode angle at about half the included angle so IE 45 degrees while doing the 90 degree portion. and a drag angle of about 5 degrees. One of the biggest things I recommend is run your roots as hot as u can stand and keep the arc as ...

- by christhewelder75

- Tue Aug 23, 2016 6:41 pm

- Forum: Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- Topic: Starting a new job

- Replies: 19

- Views: 1572

Re: Starting a new job

http://imgur.com/a/A27ww New pics from yesterday :D I've been using an everlast 200dx. A great machine I was blue biased before but this is on my list to buy when I have the $$ and the space. We got shut down due to weather yesterday afternoon and today (35kph gusting to 60+ and rain on and off) :r...

- by christhewelder75

- Sat Aug 20, 2016 9:14 pm

- Forum: Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- Topic: Starting a new job

- Replies: 19

- Views: 1572

Re: Starting a new job

I dunno if we'd be allowed to drill holes in the roof we're supposed to be sealing :$ I've figure out a decent way to tack everthing up fairly snug on the main panels so they weld up much faster. There's some sections where there's a piece of thinner material with a raised ^ in the middle that's wel...

- by christhewelder75

- Fri Aug 19, 2016 7:06 pm

- Forum: Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- Topic: Starting a new job

- Replies: 19

- Views: 1572

Re: Starting a new job

For now we are working on the gutter sections (the flat pieces) I'm not sure but I think the corrugated pieces get welded along the bottom edge to keep em water tight. I wanted to grab more pics today but left my cell at home. Was working in a much tighter area today so mostly about 45 degrees up hi...

- by christhewelder75

- Thu Aug 18, 2016 8:39 pm

- Forum: Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- Topic: Starting a new job

- Replies: 19

- Views: 1572

Re: Starting a new job

https://imgur.com/a/elY9z So first day down here's a few pics took a while but I think I found some decent settings 92amp 250hz 40/60 ac balance 1/16 electrode. Was using a gas lens but had 3 nozzles crack while welding so I just put the regular collet body back on. Unfortunately can't clamp gotta ...

- by christhewelder75

- Thu Aug 18, 2016 9:10 am

- Forum: Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- Topic: Starting a new job

- Replies: 19

- Views: 1572

Re: Starting a new job

Not my decision to use tig. When I heard the amount of weld and time frame I thought mig too. But the material is too thin I'm told.

The seams are lap joints on the bottom of the corrugated pieces I believe so on the ?--^--^--^--^ sort of like that looking down the end of the piece

The seams are lap joints on the bottom of the corrugated pieces I believe so on the ?--^--^--^--^ sort of like that looking down the end of the piece

- by christhewelder75

- Wed Aug 17, 2016 10:50 pm

- Forum: Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- Topic: Starting a new job

- Replies: 19

- Views: 1572

Re: Starting a new job

It'll be fun I'll be using a gas lens I think I'll see about taking pics once I'm there hopefully the fit up will be decent it's like corrugated. So getting comfortable will also be a challenge

- by christhewelder75

- Wed Aug 17, 2016 9:39 pm

- Forum: Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- Topic: Starting a new job

- Replies: 19

- Views: 1572

Starting a new job

So I'm starting a new job tomorrow welding seams on the roof of a new rec centre. It's 22ga aluminum done with tig using a water cooled dynasty 350 machine. There's a total of 6800 meters of weld to do by end of October and I'll be paid by the meter so the faster I work the more I can make. It's gon...

- by christhewelder75

- Mon Jul 18, 2016 3:59 pm

- Forum: Mig and Flux Core - gas metal arc welding & flux cored arc welding

- Topic: Dual Shield Welding ???

- Replies: 6

- Views: 4470

Re: Dual Shield Welding ???

One other thing to note when using self vs dual shielded is polarity. Dual uses electrode positive (dcrp) self shield u have to switch to electrode negative (dcsp) for it to run right. As far as pushing dual shield I'm of the opinion u can push or pull depending on the situation and your technique. ...

- by christhewelder75

- Mon Jul 18, 2016 3:15 pm

- Forum: Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- Topic: BCP 100 alberta pressure test

- Replies: 4

- Views: 3720

Re: BCP 100 alberta pressure test

Don't know if it's still needed but I figure more info might help someone else later. I did my B test back in dec (used tig root instead of 6010). When I started practicing it I had problems with metal bunching up in the center of the weld. I was using 3/32 7018 rod for the fill and cap for the hot ...

- by christhewelder75

- Mon Jul 18, 2016 2:48 pm

- Forum: Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- Topic: New meaning to "get comfortable"

- Replies: 9

- Views: 2925

Re: New meaning to "get comfortable"

When I was doing 3rd year schooling before xmas I was getting made fun of for laying on my back practicing my 5g smaw welds with the pipe a couple feet off the ground. I was like why not make the OH section as comfy as possible? Same when I was doing plate seams on skids while laying on my side. If ...

- by christhewelder75

- Tue Apr 14, 2015 1:14 am

- Forum: Mig and Flux Core - gas metal arc welding & flux cored arc welding

- Topic: metal core tips for structural work

- Replies: 8

- Views: 1425

metal core tips for structural work

Hey guys I recently started working in a skid shop. We use mcaw for most of our stuff and mostly 1/16th wire. I'm just looking to see if anyone has some tips to pass along I've had a couple issues with undercut here and there so I've been playing with my voltage and wire feed as well as travel speed...

- by christhewelder75

- Thu Jan 01, 2015 12:19 am

- Forum: Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- Topic: CWB FLUX CORE welding tests

- Replies: 3

- Views: 3497

Re: CWB FLUX CORE welding tests

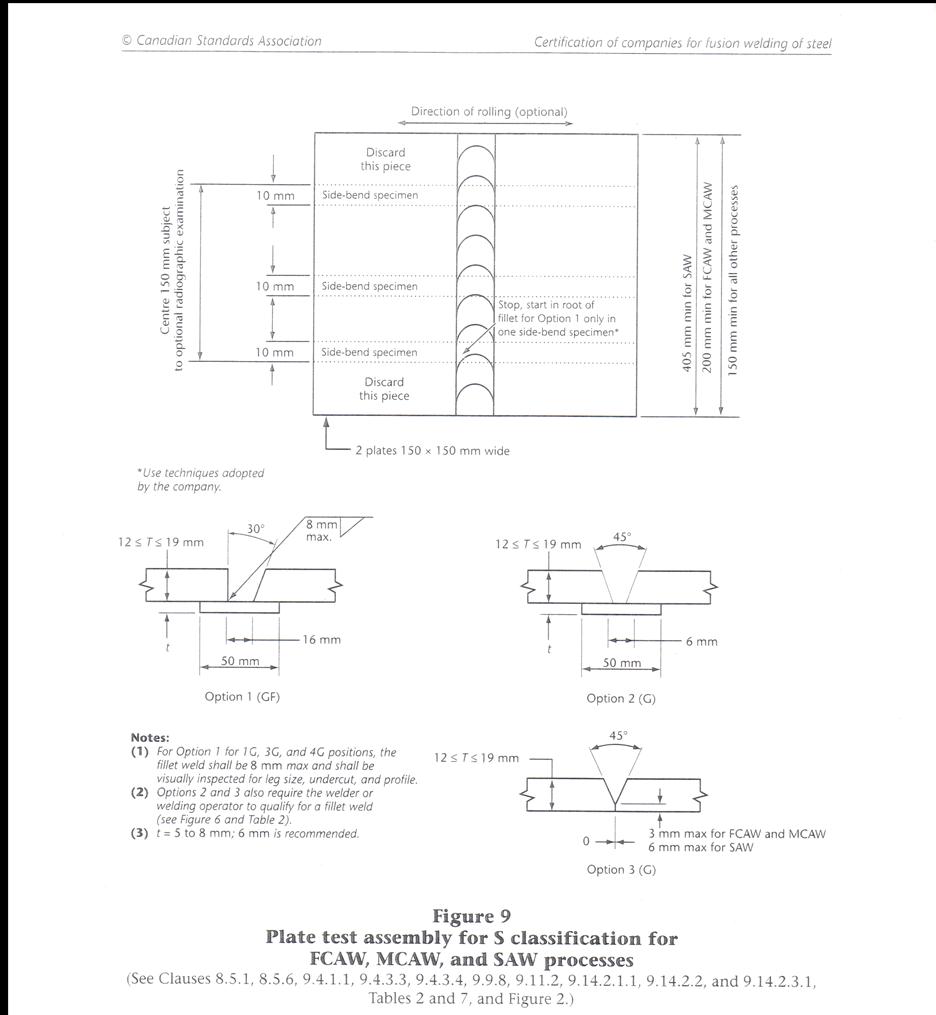

that's the diagram for the set up.

that's the diagram for the set up.On there it shows only one start/stop though some require 2 one on each root

- by christhewelder75

- Wed Dec 31, 2014 7:32 pm

- Forum: Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- Topic: CWB FLUX CORE welding tests

- Replies: 3

- Views: 3497

CWB FLUX CORE welding tests

Anyone have any CWB fcaw tickets? Any tips on passing the flat position? Any info you can give is greatly appreciated

Thanks

Thanks

- by christhewelder75

- Tue Dec 30, 2014 9:03 pm

- Forum: Mig and Flux Core - gas metal arc welding & flux cored arc welding

- Topic: FCAW settings

- Replies: 9

- Views: 9750

Re: FCAW settings

Yeah that's around where I've heard the voltage should be. Figured the boss where I took the test had the machine dialed in to where their wps would be. My buddy did the same test same settings and it passed so I know I have a couple technique changes to make as well as the settings. About how fast/...

- by christhewelder75

- Tue Dec 30, 2014 5:31 pm

- Forum: Mig and Flux Core - gas metal arc welding & flux cored arc welding

- Topic: FCAW settings

- Replies: 9

- Views: 9750

FCAW settings

Hey guys so I have a weld test next week (CWB FCAW flat 1GF). I did one similar a couple weeks ago and it didn't bend (haven't done much fcaw since July and first time on this type of test.) At the time I left the machine the way the journeyman had it set 24.7v and about 300ipm feed 0.45 wire dual s...

- by christhewelder75

- Thu Dec 04, 2014 4:40 pm

- Forum: Stick Welding/Arc Welding - Shielded Metal Arc Welding

- Topic: Amperage for pipe welding

- Replies: 14

- Views: 11706

Re: Amperage for pipe welding

personally I like a 1/8th land with a tight 3/32 gap run at about 100amps i pretty much keep pressure into the gap pushing the rod as i feel the land melt and give free then step and push. My last welding instructor was surprised i ran that hot, but the results dont lie. all my coupons bent fine. I ...

- by christhewelder75

- Sat Oct 25, 2014 8:15 pm

- Forum: Stick Welding/Arc Welding - Shielded Metal Arc Welding

- Topic: Minimum voltage for arc welder

- Replies: 22

- Views: 8197

Re: Minimum voltage for arc welder

generally you need 50-100v to strike an arc and 17.5-40v to maintain the arc while welding (at least thats true with most constant current welding machines) theoretically if u can initiate the arc that voltage would fall in the range to weld. have you got any way to adjust your amperage? higher curr...

- by christhewelder75

- Thu Oct 23, 2014 9:07 pm

- Forum: Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- Topic: Tig Trouble

- Replies: 16

- Views: 1567

Re: Tig Trouble

no worries at all steve

the system for training here in canada is a bit different from that in the US from what i understand

the system for training here in canada is a bit different from that in the US from what i understand

so so true.Postby rick9345 » Thu Oct 23, 2014 6:42 am

A good welder is their own worst critique

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities