General welding questions that dont fit in TIG, MIG, Stick, or Certification etc.

Farmwelding

- Farmwelding

-

Weldmonger

-

Posts:

-

Joined:Thu Mar 10, 2016 11:37 pm

-

Location:Wisconsin

Why do they use round tubing in auto sports and monster truck type stuff. Does it have more impact resistance than square tubing? Square is a hell of a lot easier to fab to me so round tubing must have a better quality to it. Maybe the way it interacts with the wheels and upper frame? I don't know.

A student now but really want to weld everyday. Want to learn everything about everything. Want to become a knower of all and master of none.

Instagram: @farmwelding

Nick

Instagram: @farmwelding

Nick

The round shape distributes stress in a more even manner. Due to this fact they can often engineer extra strength with less weight. I.E. smaller diameter tube with thinner walls.

I have more questions than answers

Josh

Josh

Circles, cylinders and spheres are really interesting shapes and objects for many reasons.

Geometrically it can be shown they have the greatest surface areas and volumes per unit radius and surface area which means less material for same area or volume.

Engineering wise they have consistent distance from centrum to extremity (because its round) making load calculations easier from forces coming from any direction around the diameter compared to a square shape which has varying distance from centrum to extremity.

A tumbling roll cage can be impacted from any direction and multiple directions and each has to be allowed for in strength calculations, much easier to do with a round section. Also I suspect the round tube frame will be lighter than a square tube frame with the same strength.

Geometrically it can be shown they have the greatest surface areas and volumes per unit radius and surface area which means less material for same area or volume.

Engineering wise they have consistent distance from centrum to extremity (because its round) making load calculations easier from forces coming from any direction around the diameter compared to a square shape which has varying distance from centrum to extremity.

A tumbling roll cage can be impacted from any direction and multiple directions and each has to be allowed for in strength calculations, much easier to do with a round section. Also I suspect the round tube frame will be lighter than a square tube frame with the same strength.

Flat out like a lizard drinkin'

ex framie

- ex framie

-

Ace

-

Posts:

-

Joined:Sun Aug 09, 2015 1:09 am

-

Location:Brisbane QLD Land of oz

Also round tubing is stronger with less stress raisers due to no corners.

Its a better weight to strength ratio.

Can be a bugger to weld if you're not good at constant radius welding. Like me.

Cheers

Its a better weight to strength ratio.

Can be a bugger to weld if you're not good at constant radius welding. Like me.

Cheers

Pete

God gave man 2 heads and only enough blood to run 1 at a time. Who said God didn't have a sense of humour.....

God gave man 2 heads and only enough blood to run 1 at a time. Who said God didn't have a sense of humour.....

- MinnesotaDave

-

Weldmonger

-

Posts:

-

Joined:Sun Oct 27, 2013 10:57 pm

-

Location:Big Lake/Monticello MN, U.S.A.

In addition to other comments, round tube can be bent any direction during the build process.

Dave J.

Beware of false knowledge; it is more dangerous than ignorance. ~George Bernard Shaw~

Syncro 350

Invertec v250-s

Thermal Arc 161 and 300

MM210

Dialarc

Tried being normal once, didn't take....I think it was a Tuesday.

Beware of false knowledge; it is more dangerous than ignorance. ~George Bernard Shaw~

Syncro 350

Invertec v250-s

Thermal Arc 161 and 300

MM210

Dialarc

Tried being normal once, didn't take....I think it was a Tuesday.

- MinnesotaDave

-

Weldmonger

-

Posts:

-

Joined:Sun Oct 27, 2013 10:57 pm

-

Location:Big Lake/Monticello MN, U.S.A.

Oscar wrote:What you talking about? Looks great!

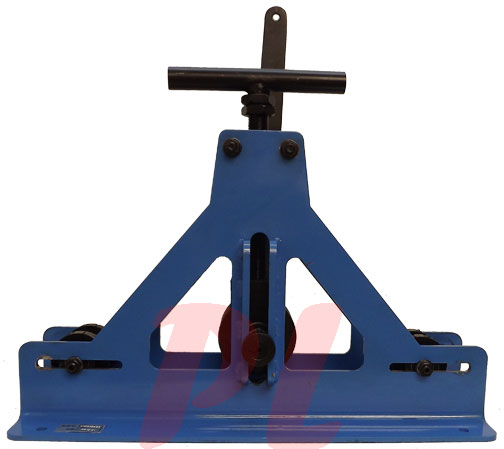

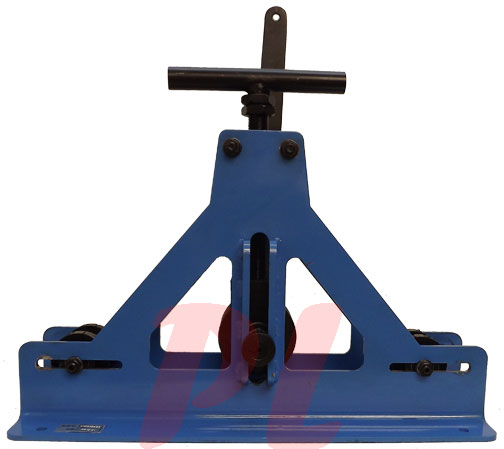

- image.png (91.55 KiB) Viewed 1900 times

Dave J.

Beware of false knowledge; it is more dangerous than ignorance. ~George Bernard Shaw~

Syncro 350

Invertec v250-s

Thermal Arc 161 and 300

MM210

Dialarc

Tried being normal once, didn't take....I think it was a Tuesday.

Beware of false knowledge; it is more dangerous than ignorance. ~George Bernard Shaw~

Syncro 350

Invertec v250-s

Thermal Arc 161 and 300

MM210

Dialarc

Tried being normal once, didn't take....I think it was a Tuesday.

You put that P.O.S. on my truck, you'll be removing it and I'll be moving on.

1.5" OD 15 ga is what I use for stuff like that.At least get a cheapo sq. die tubing roller and follow the roof line a lil.

They work OK

1.5" OD 15 ga is what I use for stuff like that.At least get a cheapo sq. die tubing roller and follow the roof line a lil.

They work OK

WildWestWelder

- WildWestWelder

-

Workhorse

-

Posts:

-

Joined:Mon Apr 03, 2017 7:43 pm

Bends are stronger (when properly executed) than welds. It looks like someone had a bunch of square pieces laying around and decided to make a welding project.Oscar wrote:What you talking about? Looks great!

Must be planning on a side roll. The lights face left and right. Not out the front. Toyota guys... They all seem confused in the trails... Maybe it's better they use square tube. God will sort them out...

- SkintOnion

-

New Member

-

Posts:

-

Joined:Tue Oct 10, 2017 12:53 pm

Bingo! Hawg huntin special!!!Poland308 wrote:You guys are looking at it wrong. It's a Texas truck. Those bars are gun rests and those are spot lights for hog hunting at night.

Sent from my iPhone using Tapatalk

Return to “Welding Forum General Shop Talk”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities