Hope everyone is doing well.

Time to upgrade good old hobart mig welder and looking at couple Miller multiprocessing machines: Multimatic 220 and Multimatic 255 where one does not come with pulse MIG and the other doesnt offer AC.

While MIG will be primary use, I definatelly like to have the option of being able to TIG weld aluminum.

How convenient and essential is pulse option vs AC option? For sure minimum spatter would be great benefit over current hobart capabilites.

Sorry if this topic has been discussed previosuly, did not find much info on the web comparing particularly these two units. Next step up would be dynasty 280dx at over $8k for their package deal. Almost twise the cost.

Welder is used primerly for prototyping and short volume small parts.

Thanks in advance for your input.

General welding questions that dont fit in TIG, MIG, Stick, or Certification etc.

I've seen some videos on YouTube, and the pulsed MIG shows everything but minimized spatter on the Miller's. At first I thought, "perhaps it's just the tacks" because he was only tack'ing, but then he made several long welds (more than just ½ second tacks), and to my eyes, it's nothing but spatter. The vast majority seem to have plenty of spatter, to my eyes. They even mention that the were using the correct 90/10 Argon/CO₂ gas.

NEjZo0iUsAk

Based on that, I don't think you'll be missing much from the pulsed-spray operation of the Miller MIG's.

Here is what pulsed-spray from my HTP MIG's looks like:

GTv1VCFKki8

As you can see, it's much, much cleaner at about 99.99% spatter-free. Only the arc initiation (the first ¼ second or so) shows the tiniest of spatter. The proof is in the pudding.

So, essential? Nah, I don't think so. Convenient? Heck yea. Not having to deal with spatter on MIG is a real nice luxury.

NEjZo0iUsAk

Based on that, I don't think you'll be missing much from the pulsed-spray operation of the Miller MIG's.

Here is what pulsed-spray from my HTP MIG's looks like:

GTv1VCFKki8

As you can see, it's much, much cleaner at about 99.99% spatter-free. Only the arc initiation (the first ¼ second or so) shows the tiniest of spatter. The proof is in the pudding.

So, essential? Nah, I don't think so. Convenient? Heck yea. Not having to deal with spatter on MIG is a real nice luxury.

Hobart Ironman 240 is virtually spatter free when tuned within reason, and without pulse. Only time I get even a single little BB is when I left a bit too much stick out at arc initiation.

It's a bit off topic, I know, but wanted to share anyway since people are talking about spatter.

It's a bit off topic, I know, but wanted to share anyway since people are talking about spatter.

Depends on what you want to weld. Realistically, how much do you actually weld aluminum? AND, would the MM255 with either a spool gun or a push/pull gun meet your aluminum welding needs? Me personally I am ditching my TIG welder, as I never use it. 99% of what I weld is either short arc MIG or dual shield flux core, as all my projects and repairs have been steel. The rest has been stick welding. If I really feel the need to weld some aluminum and it can't be done with a spool gun, I will go buy a cheap 200 amp inverter TIG. There are many of those out there for under or around $1K, and honestly they probably do a better job than the MM220, which doesn't even do pulse TIG on AC. If you are primarily a MIG guy, go for the amps and get the 255

Multimatic 255

Oscar, your shill is showing again! I really don't think you can make a reasonable judgement from the Baker's gas videos. Who knows if the settings are correct or if he has something way out of scope, like arc length or whatever. Based on the sound of the arc alone, I think it is a safe bet that machine is not set correctly. We get it, you love HTP machines. That's cool. But until you get your hands on the MM255, I don't think it is fair for you to bash it.Oscar wrote:I've seen some videos on YouTube, and the pulsed MIG shows everything but minimized spatter on the Miller's. At first I thought, "perhaps it's just the tacks" because he was only tack'ing, but then he made several long welds (more than just ½ second tacks), and to my eyes, it's nothing but spatter. The vast majority seem to have plenty of spatter, to my eyes. They even mention that the were using the correct 90/10 Argon/CO₂ gas.

Multimatic 255

No Louie, no shill here. Like I said before, I don't take hand-outs and I earn every penny I've spent on my gear. So that remark I sure do not appreciate, yet again. None the less, perhaps the Miller was out of whack, who knows. I was surprised myself. You'd think a large outfit like Baker's would have the know-how to set-it up correctly, especially when they're making those demonstration videos. I'd expect for them to. So what, now I can't speculate on my own? I'm pretty sure I'm free to speculate based on what I see....

I often come across "review" videos from Baker's and I always take them with a grain of salt, because at the end of the day, they are a vendor looking to make money from the sale of welding machines and supplies, and probably have specific relationships with many of the producers making those machines and supplies. Not saying they aren't often good, useful, informative videos. They are. I just keep their motivation and purpose in the back of my mind. Not the same as an independent reviewer.

I agree, they need to sell machines. Makes me wonder why they wouldn't just call up Miller and make sure they are setting things up correctly though? I'm pretty sure they have a rep they can get to, seeing as how they are likely a high volume Miller dealer, to help them set it up correctly. I'm all for that machine getting pulse right; for the money it costs, I sure hope someone does prove my speculation wrong and shows really great pulsed-MIG welds with it.Spartan wrote:I often come across "review" videos from Baker's and I always take them with a grain of salt, because at the end of the day, they are a vendor looking to make money from the sale of welding machines and supplies, and probably have specific relationships with many of the producers making those machines and supplies. Not saying they aren't often good, useful, informative videos. They are. I just keep their motivation and purpose in the back of my mind. Not the same as an independent reviewer.

In the video he said straight away he was using default settings for auto-setup on 3/16 material. IOW, no settings at all. To be honest, I was surprised they'd even post a video showing it spitting sparks all over hell like that. I mean it was like fireworks caught on camera in a 24" sphere from the arc.

Demonstrations by "Merchants" who probably hold not a single certification are completely arbitrary. This is why Jody's video are so valuable. His credentials speak for themself.

Suddenly, pulse-MIG is all the rage. Think about the billions of miles of welds performed without it and those structures still stand. Oh dear, we should all throw away our MIG boxes and rush out to buy brand new P-M units.

Suddenly, pulse-MIG is all the rage. Think about the billions of miles of welds performed without it and those structures still stand. Oh dear, we should all throw away our MIG boxes and rush out to buy brand new P-M units.

TraditionalToolworks

- TraditionalToolworks

-

Weldmonger

-

Posts:

-

Joined:Mon Dec 18, 2017 7:49 am

-

Location:San Jose / Kelseyville

Wait a second...I thought spray-MIG was the craze?cj737 wrote:Suddenly, pulse-MIG is all the rage.

It was my impression if you don't spray-MIG you're not very high on the food chain?

Standing structures are so overrated.

Collector of old Iron!

Alan

Alan

Yea but it is on Pulse, which if I'm not mistaken has it's own Auto-Set program. AFAIK, that doesn't mean that because he is using Auto-set that it is somehow defaulted back into short circuit MIG, because he already has it on pulse mode. Based on my old MM211, the Auto-Set is pretty accurate, so I'd expect the Pulse Auto-Set to also be pretty accurate as well. So yea, contrary to what Louie thinks, I'm not bashing it and would love to see what it can really do if it is indeed out of whack and needs to be adjusted further than what the Pulse Auto-set produces. Bashing,IMO, would be "that's a POS, it sucks, etc". I'm just calling it how I see it, because I have yet to see any other videos of it producing a nice pulsed-MIG result (from my perspective). So more like "informative discussion", as I see it. If anyone can find a good video of it on pulse, that would be great to see.BugHunter wrote:In the video he said straight away he was using default settings for auto-setup on 3/16 material. IOW, no settings at all. To be honest, I was surprised they'd even post a video showing it spitting sparks all over hell like that. I mean it was like fireworks caught on camera in a 24" sphere from the arc.

BillE.Dee

- BillE.Dee

-

Weldmonger

-

Posts:

-

Joined:Mon Nov 27, 2017 8:53 pm

-

Location:Pennsylvania (Northeast corner)

I watched both videos. Without doubt the htp is very impressive in that there are NO fireworks as compared to the miller display. Are the settings on the miller ferhoodled? I don't know. Is the fact that one is using 035 and the other using 030 making a difference? I don't know, BUT I would imagine that the settings would be different.

Has anyone contacted MILLER about a viable video on the process??? I'm willing to get in their britches and learn something. I don't know anyone around me that is using the pulse spray on anything. Seems that the dark ages do exist. I will try to make contact with Earth and see what is happening.

Has anyone contacted MILLER about a viable video on the process??? I'm willing to get in their britches and learn something. I don't know anyone around me that is using the pulse spray on anything. Seems that the dark ages do exist. I will try to make contact with Earth and see what is happening.

I guess no one really knows as we have yet to have any empirical evidence of it that someone has publicly documented on the internet. If you've ever actually looked at a close-up of the display for those newer Millers that have the LCD display, it's very clear where the settings are, and the range of acceptable settings as per Miller. Kinda hard to screw it up. Look up online pictures of the display for Auto-Set by any means necessary and you will see. It has a nice intuitive display for Auto-Set parameters.BillE.Dee wrote:I watched both videos. Without doubt the htp is very impressive in that there are NO fireworks as compared to the miller display. Are the settings on the miller ferhoodled? I don't know.

Look I found one. How easy is that? Seriously. How. Easy. Is. That.

Also, don't get me wrong, the HTP MIGs aren't perfect; for example, on my PP200/220MTS, when in the steel pulse program under about 55-60A, I find the arc just a wee bit erratic and I find myself adding just a smidge extra voltage in some situations. By erratic I mean, that in a say 5" long weld, I'll get 4-6 tiny "pops" and you'll see the tiniest of spatter for a couple tenths of a second or so, just a quick "buzzz" here and there. Could just be the wire, could be my gas, could be the machine, could be the work clamp, who knows. The few extra tenths of a volt help smooth it out. Definitely not perfect.

As others have said, would a spoolgun handle any potential aluminum welding you think you might do? The question is effectively between having the ability to tig weld aluminum and having a much higher output and duty cycle for mig and tig.

Thank you all gents for the suggestions.sbaker56 wrote:As others have said, would a spoolgun handle any potential aluminum welding you think you might do? The question is effectively between having the ability to tig weld aluminum and having a much higher output and duty cycle for mig and tig.

I don't have experience with spoolgun. Although our Hobart has it, it has never been used. I don't think spool gun is suitable for what we do.

We use the welder for business, however it is not a primary equipment that requires long duty cycles or heavy welding.

Cost is not a factor and I am not looking for a budget package. We plan on doing tutorials on the products we make and offer with the shop being in the background, and I would like to upgrade some of our day to day used equipment. Of course from practical stand point I don't need a welder meant for mostly industrial heavy duty use as that is not what we do. The reason I was considering a multi processing machine was it is practical, however the more I research the more I lean toward two dedicated machines: MIG and AC'/DC TIG.

I am now shifting my choice from Miller to HTP. The two units I am considering are an overkill and way too much of welders for what we do, but I don't plan on buying another welder in a long time.

For MIG I am looking at ProPulse 300 and for TIG Invertig 313.

Let me know if anyone here has first hand experience with these machines. Company seems to stand behind their name and build quality looks not less than Miller.

We weld mostly mild steel tubing, plates, nuts, flat bars up to 50mm, round bars up to 1/2" etc. We work 99% with metric material: square or round tubes from 10mm to 35mm diameter. Thickness from 1.5 to 2.5mm

We weld a lot of M10 nuts on those tubes. bicycle style clamps etc. We may start making some aluminum parts where AC TIG would come handy.

Most of the stuff we do is thin mild steel and small/short beads. All prototypes and production parts we do are for consumer use (not industrial of any sort).

The majority of our production batch parts are made by our suppliers however we often make custom parts in-house or short batch / low volume parts.

We powder coat in-house most of the stuff we fabricate.

While mig welding is sufficient, and the powder coat covers most imperfections it is still desired to have more precise capabilities as TIG has.

Sounds to me like you have not really explored all the options yet. Don't give up on the spool gun just because you don't have anybody who has it figured out yet. Like every other process, it is not as simple as it seems. Yes, once somebody shows you all the nuance, now it's easy. But up until that point, you can make a lot of ugly useless welds with a spool gun and think that somehow it's inferior. You just have to give it a fair shake and not with some beginner making their third weld.

That's not to say that another process isn't Superior. It really depends upon what you're trying to do. I'm just trying to say, don't shy away from them because you don't know anybody in the company who can make it work. They are a very useful tool and they are one hell of a lot faster than Tig.

That said, it sounds like you really don't do aluminum or stainless all that often. If your primarily doing steel the spool gun never comes into it.

I would say if you make a list of all the things you are currently not happy with, try to address them. You gave such a vague description of what you're not happy with that you make it tough to recommend a solution.

That's not to say that another process isn't Superior. It really depends upon what you're trying to do. I'm just trying to say, don't shy away from them because you don't know anybody in the company who can make it work. They are a very useful tool and they are one hell of a lot faster than Tig.

That said, it sounds like you really don't do aluminum or stainless all that often. If your primarily doing steel the spool gun never comes into it.

I would say if you make a list of all the things you are currently not happy with, try to address them. You gave such a vague description of what you're not happy with that you make it tough to recommend a solution.

dmp, while I don't have an Invertig 313 per-say, it is simply an amperage-detuned little brother of my Invertig 400. Features and functions are identical. It is simply just limited to 300A. The Pro Pulse 300 I've used with solid-wire from the ER70-S class, gasless flux core wire FCAW-S E71T-11 class, gas shielded flux core FCAW-G E71T-1C/1M class, metal-core wire E70C-6M class, ER4043 & ER5356 aluminum wire through a water-cooled 10ft MIG gun, as well as a stick welder. The full manual-pulse (MIG & Stick)/manual double-pulse mode (MIG) is insanely awesome.

Thanks Oscar. I actually commented on one of your videos on youtube. I later realized the 313 package with water cooler comes with cart, torch and few other accessories which made more sense price wise compared to the 400amp unit.Oscar wrote:dmp, while I don't have an Invertig 313 per-say, it is simply an amperage-detuned little brother of my Invertig 400. Features and functions are identical. It is simply just limited to 300A. The Pro Pulse 300 I've used with solid-wire from the ER70-S class, gasless flux core wire FCAW-S E71T-11 class, gas shielded flux core FCAW-G E71T-1C/1M class, metal-core wire E70C-6M class, ER4043 & ER5356 aluminum wire through a water-cooled 10ft MIG gun, as well as a stick welder. The full manual-pulse (MIG & Stick)/manual double-pulse mode (MIG) is insanely awesome.

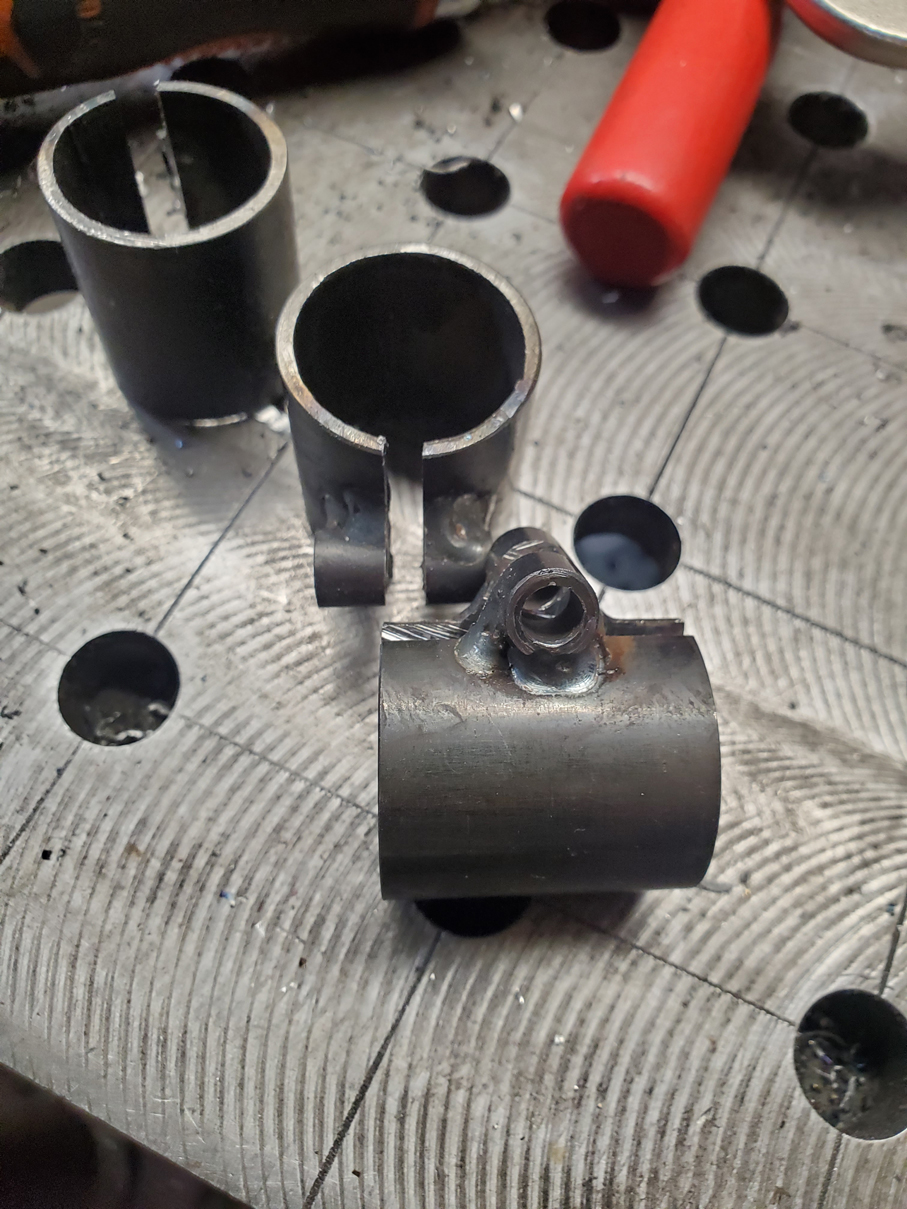

Here is an exampleBugHunter wrote:Sounds to me like you have not really explored all the options yet. Don't give up on the spool gun just because you don't have anybody who has it figured out yet. Like every other process, it is not as simple as it seems. Yes, once somebody shows you all the nuance, now it's easy. But up until that point, you can make a lot of ugly useless welds with a spool gun and think that somehow it's inferior. You just have to give it a fair shake and not with some beginner making their third weld.

That's not to say that another process isn't Superior. It really depends upon what you're trying to do. I'm just trying to say, don't shy away from them because you don't know anybody in the company who can make it work. They are a very useful tool and they are one hell of a lot faster than Tig.

That said, it sounds like you really don't do aluminum or stainless all that often. If your primarily doing steel the spool gun never comes into it.

I would say if you make a list of all the things you are currently not happy with, try to address them. You gave such a vague description of what you're not happy with that you make it tough to recommend a solution.

This is a 30mm round tube, with 7mm diameter tube welded on it. Part will be powder coated. While mig welder does it just fine it is a pain to weld 100 of these without spatter, burning through material or just wire touches wrong spot and ruins it. We weld and then cut these as a two step process held on custom made jig with 3pcs at the time.

Again welding is not my main trade and I am not an expert, I believe tig would do a better job here. Pulse MIG would probably make process easier too with cleaner final result.

Oh ok, hopefully you liked my awesome video productionDmp wrote:Thanks Oscar. I actually commented on one of your videos on youtube. I later realized the 313 package with water cooler comes with cart, torch and few other accessories which made more sense price wise compared to the 400amp unit.Oscar wrote:dmp, while I don't have an Invertig 313 per-say, it is simply an amperage-detuned little brother of my Invertig 400. Features and functions are identical. It is simply just limited to 300A. The Pro Pulse 300 I've used with solid-wire from the ER70-S class, gasless flux core wire FCAW-S E71T-11 class, gas shielded flux core FCAW-G E71T-1C/1M class, metal-core wire E70C-6M class, ER4043 & ER5356 aluminum wire through a water-cooled 10ft MIG gun, as well as a stick welder. The full manual-pulse (MIG & Stick)/manual double-pulse mode (MIG) is insanely awesome.

Yea, that looks like you simply have the heat set too high. Turn down both the power and the wire feed speed, and turn the power down a lot. You don't need a ton of amps to weld stuff that's that light. There's undercut something terrible on that boss you welded. That's enough to tell you the welder needs turned down.Dmp wrote:BugHunter wrote: Here is an example

This is a 30mm round tube, with 7mm diameter tube welded on it. Part will be powder coated. While mig welder does it just fine it is a pain to weld 100 of these without spatter, burning through material or just wire touches wrong spot and ruins it. We weld and then cut these as a two step process held on custom made jig with 3pcs at the time.

Again welding is not my main trade and I am not an expert, I believe tig would do a better job here. Pulse MIG would probably make process easier too with cleaner final result.

Return to “Welding Forum General Shop Talk”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities