General welding questions that dont fit in TIG, MIG, Stick, or Certification etc.

mcwille117

- mcwille117

-

New Member

-

Posts:

-

Joined:Fri Nov 01, 2013 8:43 pm

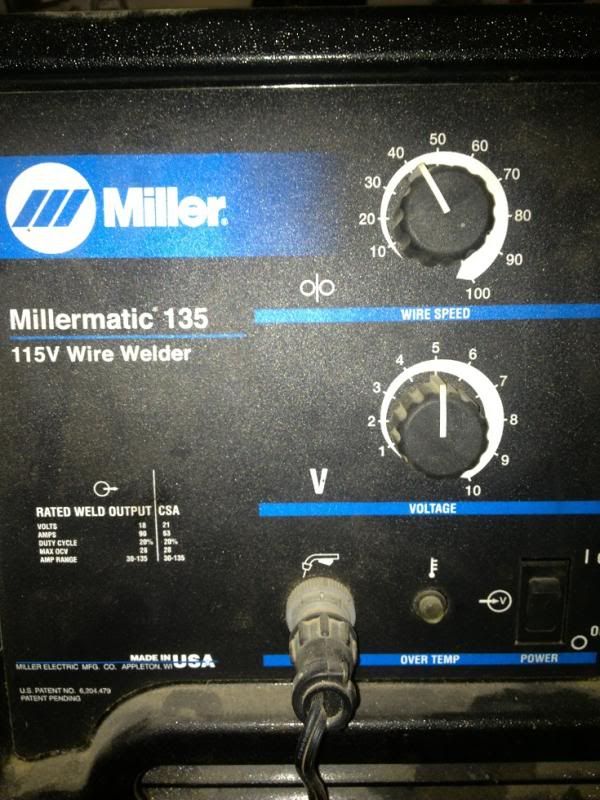

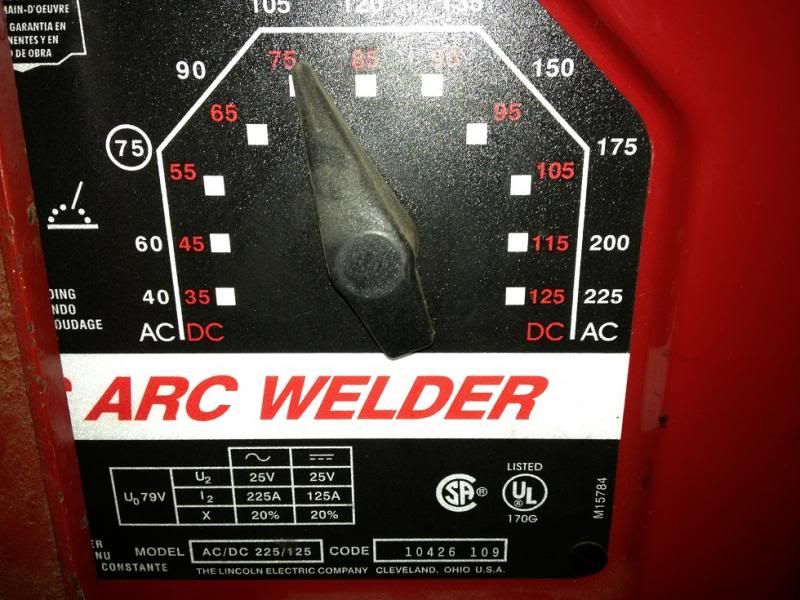

Hi, in the past I have taken community college welding classes and welded aluminum with TIG and with a spool-gun MIG setup. I found TIG to be the more frustrating of the two. In my TIG class aluminum was the only metal in any position that caused me any frustration. A few classes later in auto-body class I tried welding aluminum with a spool-gun and it comparatively was so easy I almost soiled myself in frustration at the difference. Now it has been a few years and I would like Make a few things out of aluminum. No sheet metal thin stuff, 0.25" angle-brackets and U-channels. Maybe some expanded sheet, but even that would still be 0.25" thick. Trying to cut costs and deciding whether the cost of new equipment or paying someone to build what I need is my focus. I have two machines in my possession and would love to "modify" one if possible to meet my needs. I remember from my TIG class that aluminum was welded at a different polarity, does this hold true for MIG? If so than can my Lincoln Electric AC/DC Arc Welder, handle the job if I bought a spool-gun and made a gas setup? Or could my Millermatic 135 wire feed welder do the job if I bought new feed rollers, liner, and whatever else it would need? I will post images of both welders with specs. I would love to do this without purchasing a whole new machine. At the price of a new machine it would be more cost effective to pay a shop.  I would like to use this project as a stepping stone for future ones so in the long run I would hate cut out the experience because it isn't cost effective.

I would like to use this project as a stepping stone for future ones so in the long run I would hate cut out the experience because it isn't cost effective.

mcwille117

- mcwille117

-

New Member

-

Posts:

-

Joined:Fri Nov 01, 2013 8:43 pm

I don't think you have enough power with your GMAW set-up. .25 aluminum takes more amperage than what you have available. With your stick welder you would have to set up scratch start GTAW and, while it works ok on steel, you would have all sorts of problems with aluminum.

So, to answer your question, in a word, no, either buy a new machine or have it done by someone else.

What you have is a good and economical set-up for steel. Small GMAW for the thin stuff and a capable SMAW welder for thicker sections.

So, to answer your question, in a word, no, either buy a new machine or have it done by someone else.

What you have is a good and economical set-up for steel. Small GMAW for the thin stuff and a capable SMAW welder for thicker sections.

mcwille117

- mcwille117

-

New Member

-

Posts:

-

Joined:Fri Nov 01, 2013 8:43 pm

Thank you for a response. So there really wouldn't be away put a spool-gun setup on the stick welder and not have it be a scratch start like I weld with the sticks? That is a bummer. I guess I will start pricing out what it will cost to pay someone.

mcwille117

- mcwille117

-

New Member

-

Posts:

-

Joined:Fri Nov 01, 2013 8:43 pm

mcwille117

- mcwille117

-

New Member

-

Posts:

-

Joined:Fri Nov 01, 2013 8:43 pm

Thank you for noticinglazerbeam wrote: What you have is a good and economical set-up for steel. Small GMAW for the thin stuff and a capable SMAW welder for thicker sections.

- weldin mike 27

-

Weldmonger

-

Posts:

-

Joined:Fri Apr 01, 2011 10:59 pm

-

Location:Australia; Victoria

One option still available to you is Alum electrodes for your stick welder. There is a large amount brands on the market, varying from really crap and cheap to sort of good and expensive. They do take alot of practice to get get good results, but it is an option.

Mick

Mick

No, the stick welder uses current in a different way than GMAW so it will not work. Your GMAW welder would probably weld 1/8" aluminum if it is spool gun compatible. Most Miller GMAW machines are so you may be in luck.mcwille117 wrote:Thank you for a response. So there really wouldn't be away put a spool-gun setup on the stick welder and not have it be a scratch start like I weld with the sticks? That is a bummer. I guess I will start pricing out what it will cost to pay someone.

They do make stick electrodes for aluminum but I have not had any luck with them. My welds with the aluminum electrodes looked terrible.

- Otto Nobedder

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 06, 2011 11:40 pm

-

Location:Near New Orleans

That Lincoln will run a spool-gun just fine, in DC+, and easily weld 1/4".

You'll be stunned what a good-quality spool-gun can cost, though. I'd have to do Craigslist or Ebay. You'll still be adding in a bottle of 100% argon and possibly a flowmeter if you haven't one with your Miller.

Be aware, the Lincoln is a constant-current machine, rather than constant-voltage, and you'll have to select your spool gun accordingly. Like "suitcase" MIG, they are available CC, CV, and switchable.

I agree with the previous post that the 110V miller will not have the capacity to weld 1/4" aluminum. It "may" be able to do 1/8", with a teflon liner and .030 wire, and a good pre-heat. If you go this route, I'd choose 5356 wire for it's stiffness (easier feed from a push-only MIG).

Let us know how you choose to go forward.

Steve S

You'll be stunned what a good-quality spool-gun can cost, though. I'd have to do Craigslist or Ebay. You'll still be adding in a bottle of 100% argon and possibly a flowmeter if you haven't one with your Miller.

Be aware, the Lincoln is a constant-current machine, rather than constant-voltage, and you'll have to select your spool gun accordingly. Like "suitcase" MIG, they are available CC, CV, and switchable.

I agree with the previous post that the 110V miller will not have the capacity to weld 1/4" aluminum. It "may" be able to do 1/8", with a teflon liner and .030 wire, and a good pre-heat. If you go this route, I'd choose 5356 wire for it's stiffness (easier feed from a push-only MIG).

Let us know how you choose to go forward.

Steve S

mcwille117

- mcwille117

-

New Member

-

Posts:

-

Joined:Fri Nov 01, 2013 8:43 pm

1/8" really doesn't get me where I want to be and still having to preheat would possibly be a nightmare contaminating the welds i would think. as far as a spool-gun I was thinking something along the lines of:Otto Nobedder wrote:That Lincoln will run a spool-gun just fine, in DC+, and easily weld 1/4".

You'll be stunned what a good-quality spool-gun can cost, though. I'd have to do Craigslist or Ebay. You'll still be adding in a bottle of 100% argon and possibly a flowmeter if you haven't one with your Miller.

Be aware, the Lincoln is a constant-current machine, rather than constant-voltage, and you'll have to select your spool gun accordingly. Like "suitcase" MIG, they are available CC, CV, and switchable.

I agree with the previous post that the 110V miller will not have the capacity to weld 1/4" aluminum. It "may" be able to do 1/8", with a teflon liner and .030 wire, and a good pre-heat. If you go this route, I'd choose 5356 wire for it's stiffness (easier feed from a push-only MIG).

Let us know how you choose to go forward.

Steve S

http://www.homedepot.com/p/Lincoln-Elec ... ifications

Craigslist has one of those used for $100. Could I make that work with the Lincoln if I use the gas setup for the Miller with 100% argon? I have a bottle of 100% that i got for the miller and never used.

Next thought was to go this route:

http://www.aliexpress.com/item/CT-312-T ... 01939.html

Although then I would be back trying to TIG aluminum, which was not fun in class. However with practice it my be better in the long run. Would this machine handle 1/4" aluminum?

I can get my father behind purchasing this machine because he wants a plasma cutter.

- Otto Nobedder

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 06, 2011 11:40 pm

-

Location:Near New Orleans

I don't think that spool-gun is a "stand-alone" that will work with a constant-current source. It has a remote cable, and is designed to operate with a CV MIG unit.

The TIG you posted does not apear to have HFAC capability, which is essential for aluminum welding at that power level. Even in the Chinese market, you'll have to spend more money to TIG aluminum.

Sorry.

Steve S

The TIG you posted does not apear to have HFAC capability, which is essential for aluminum welding at that power level. Even in the Chinese market, you'll have to spend more money to TIG aluminum.

Sorry.

Steve S

noddybrian

- noddybrian

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 24, 2013 12:13 pm

I have no experience of this spool gun & the price is so low even for an import I don't know what to expect of it - but if you really want to weld aluminum on a budget so long as you can source argon it should work with your stick welder - maybe if anyone has seen one they can comment on what it's like.

http://www.ebay.co.uk/itm/ALIMINIUM-SPO ... 485c3befdb

Amusing Chinese video of it in use. http://www.youtube.com/watch?v=lrpQtijqe0g

http://www.ebay.co.uk/itm/ALIMINIUM-SPO ... 485c3befdb

Amusing Chinese video of it in use. http://www.youtube.com/watch?v=lrpQtijqe0g

Well, I learned something today. I did not know that stand-alone spool guns existed. I bought my first one way back when I got my first 250 series Millermatic it was still going strong when I retired. If they will work with the CC-DCEP you have available then you are in business for .25 aluminum.

noddybrian

- noddybrian

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 24, 2013 12:13 pm

Stand alone spool on's have been around probably before any dedicated or Euro fitted torch that is common today - the one I used for years had it's own control box which plugged into 110 volt & provided power to the wire drive - it had two range settings & the wire speed control was on the bottom of the torch - down side was it had a really thick hose assembly on it - I still have the torch but the original controller packed up a while back - I now have it wired so I can plug it into my larger 500amp Mig set - clumsy but functional & it will drive quite large diameter wire - would'nt like to guess the age - but judging by the components in the controller no later than 60's !

That import thing on Ebay kinda tempts me - I know I should look for better but it's stated as being good for 200amps @60% duty which is'nt that bad & I almost never need a spool on - but with that a small inverter plus small size bottle it would be so portable if needed for a trailer repair or similar.

In a recent video ChuckE's new mate ( Schneetigger 77 ) was running a stand alone on a Miller Trailblazer - think that was an HTP - they seem to like that brand at the moment - hard to say as they make their buck from pushing brand names on their channel.

That import thing on Ebay kinda tempts me - I know I should look for better but it's stated as being good for 200amps @60% duty which is'nt that bad & I almost never need a spool on - but with that a small inverter plus small size bottle it would be so portable if needed for a trailer repair or similar.

In a recent video ChuckE's new mate ( Schneetigger 77 ) was running a stand alone on a Miller Trailblazer - think that was an HTP - they seem to like that brand at the moment - hard to say as they make their buck from pushing brand names on their channel.

Return to “Welding Forum General Shop Talk”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities