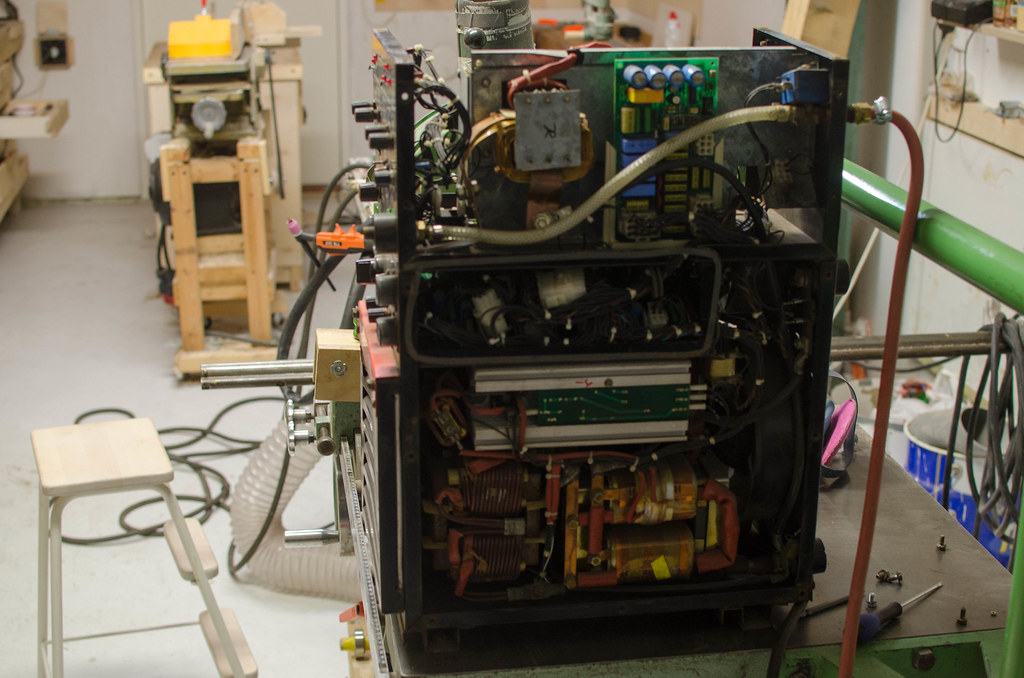

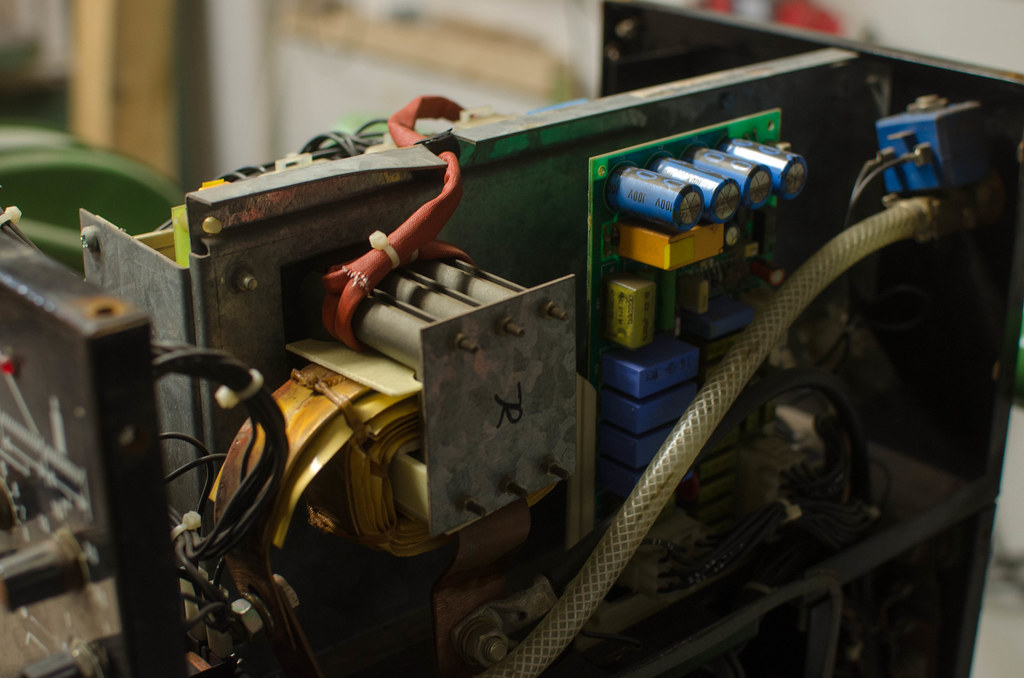

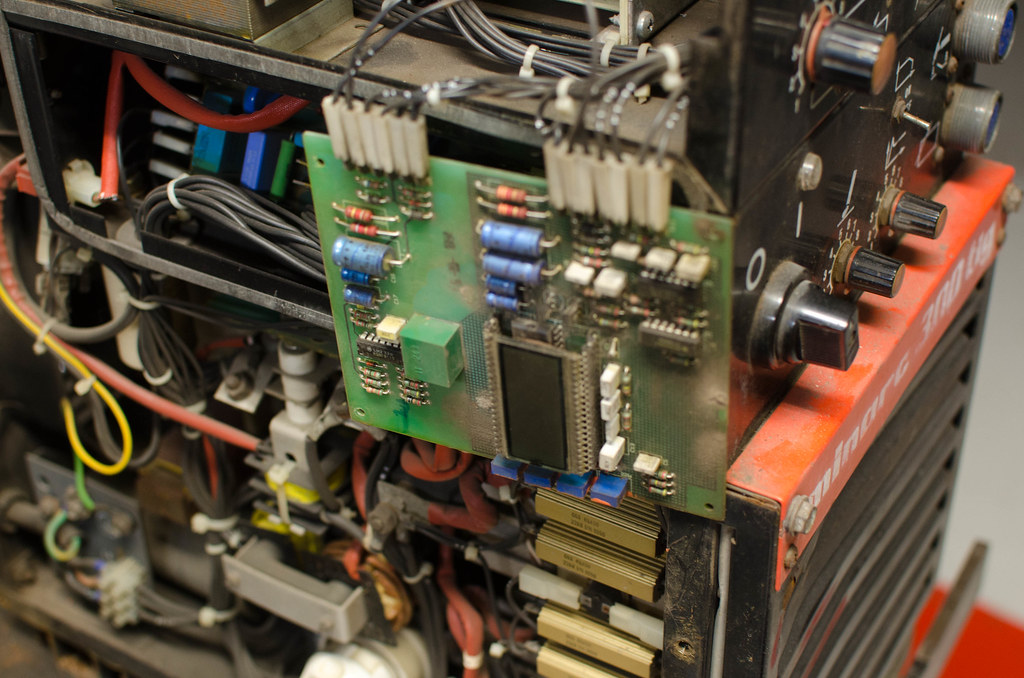

But it does have a strange quality, it squeals when you weld with it and the noise changes based on the arc length, same in both stick and TIG mode. I sorta find it helpful as I can use the noise as additional feedback on my arc, but also a bit annoying...

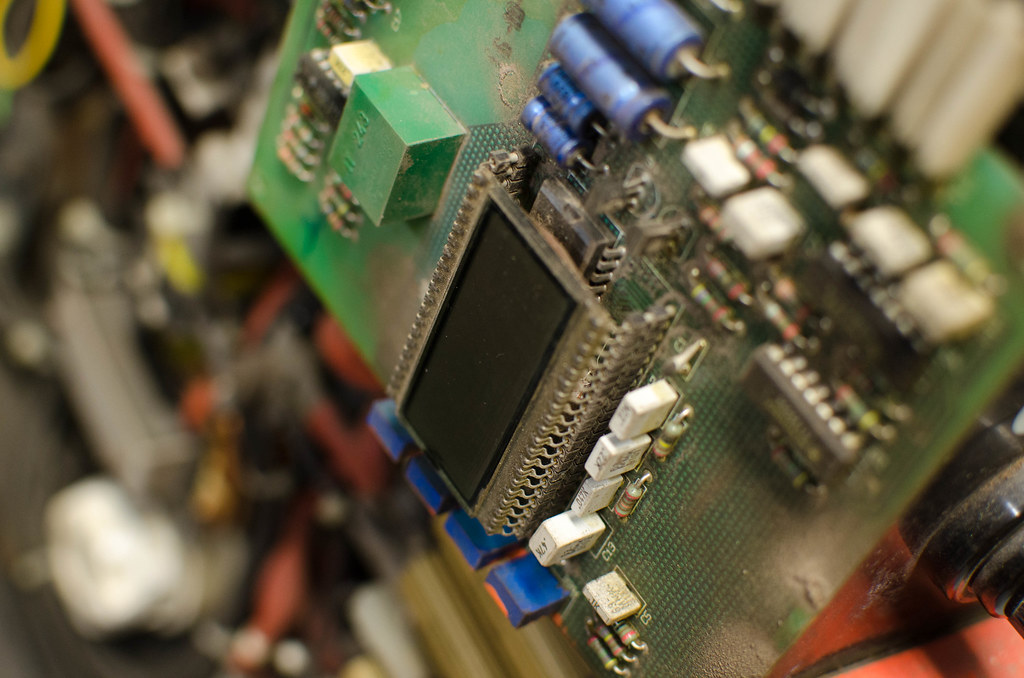

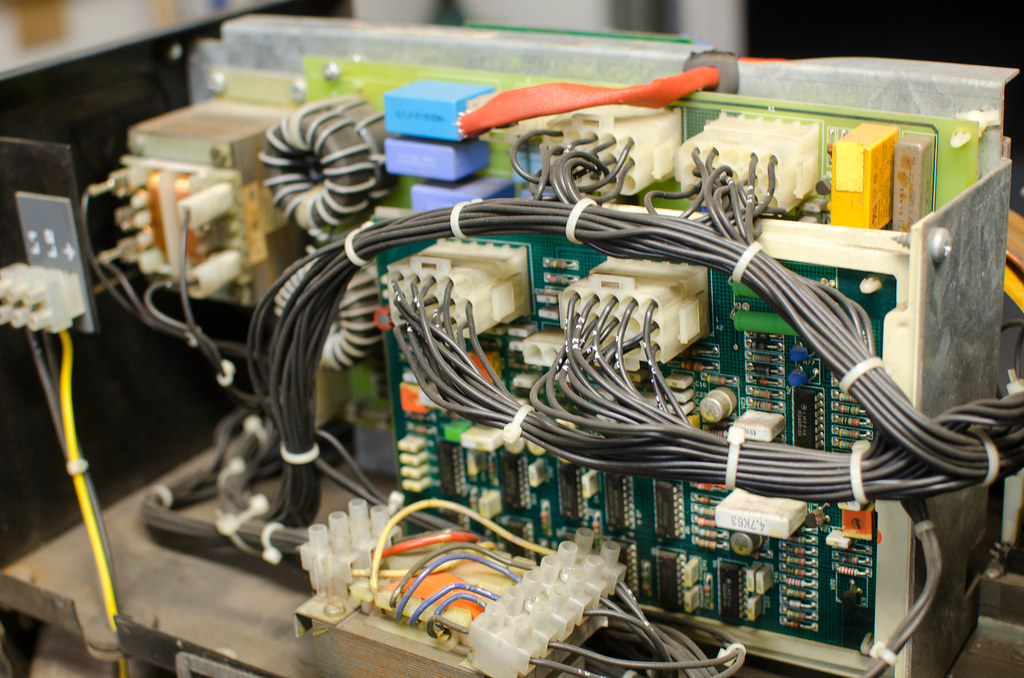

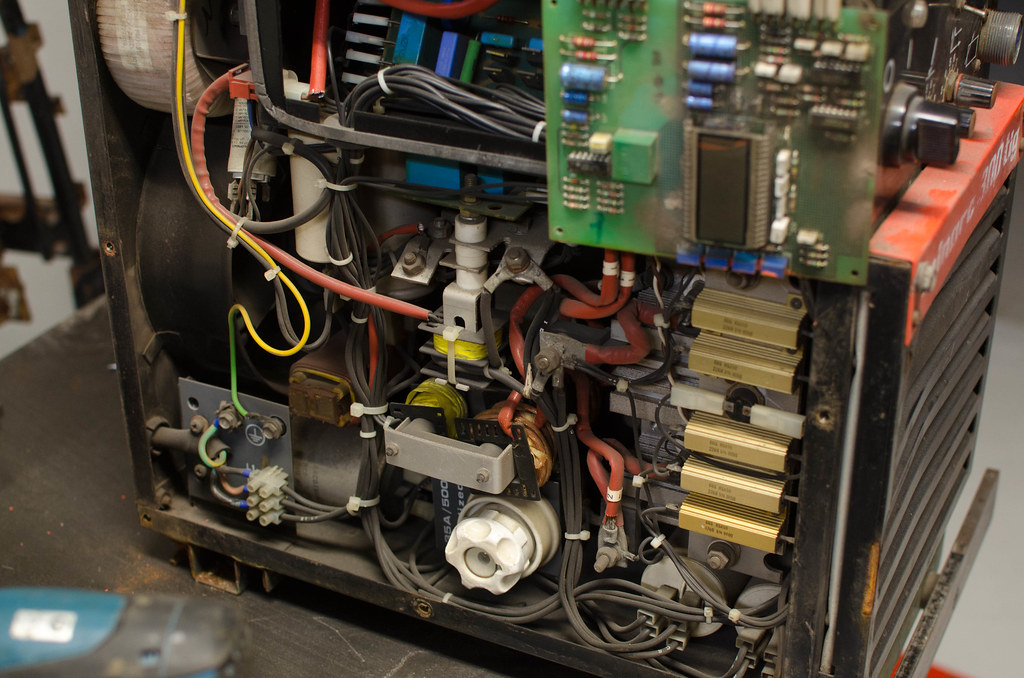

BUT, I've googled it and from what I can see a lot of these Kemppi machines are squealers and it's part of normal function. My question is why? It seems to apply mainly to older machines, does it have something todo with older inverter technology used in these machines perhaps? Does the fact that it's a 3-phase machine result in some design quirks that lead to this noise?

I found one reference to a kemppi being a squealer:

http://weldingweb.com/showthread.php?34 ... vice/page2

So is this perhaps the reason? If I get this right older models of inverters where slower frequency and have a tendency to squeal, so is this the reason? And they apparently have nice welding qualities? If so why aren't they around any more?It's just flat out a "stud" and if you ever see what the slower frequency inverters (squealers) do when tig-ing or stick welding sluggish fillers it's amazing. (it will even "pulse" SMAW which is just evil with Ni-rod).