Hi All

Got my Tungstens today and thought they would have been ground to a point, No joy so i tried myself please let me know if this is OK. Thanks.

General welding questions that dont fit in TIG, MIG, Stick, or Certification etc.

exnailpounder

- exnailpounder

-

Weldmonger

-

Posts:

-

Joined:Thu Dec 25, 2014 9:25 am

-

Location:near Chicago

That's gonna work fine! You are going to get to a point , one day, that when you need to sharpen, you will sharpen the same way and you will just know how to weld with it and be fine. Don't overthink it and have fun. It's only weldinginfernoST wrote:Hi All

Got my Tungstens today and thought they would have been ground to a point, No joy so i tried myself please let me know if this is OK. Thanks.

Tungsten.JPG

Ifyoucantellmewhatthissaysiwillbuyyouabeer.

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

No, they won't arrive ground to a point.

Possibly because needs vary - sharp point? Blunt point?

Although the pic is a bit iffy, I think I can see enough to make out that the grinding marks are longitudinal, and that's good. You just don't want grinding marks circling around the point of the tip; that messes up your arc.

I think you are probably in good shape with that. What are you going to be welding?

Kym

Possibly because needs vary - sharp point? Blunt point?

Although the pic is a bit iffy, I think I can see enough to make out that the grinding marks are longitudinal, and that's good. You just don't want grinding marks circling around the point of the tip; that messes up your arc.

I think you are probably in good shape with that. What are you going to be welding?

Kym

Sorry for the crappy photo, It is ground longitudinal, I'm going to try laying beads on mild steel until i get the feel for it then try aluminum. I should be picking up my Argon tomorrow and the 220 line should be done by next weekend. I can only use 120vac for now.

Keith

- LtBadd

-

Weldmonger

-

Posts:

-

Joined:Sun Apr 12, 2015 4:00 pm

-

Location:Clearwater FL

-

Contact:

Looks good, if at some time you want more information Diamond Ground Products has a tungsten guidebook that is a good read. That is, at least as far as tungsten CAN be a good read, well it is good information anyway.infernoST wrote:Sorry for the crappy photo, It is ground longitudinal, I'm going to try laying beads on mild steel until i get the feel for it then try aluminum. I should be picking up my Argon tomorrow and the 220 line should be done by next weekend. I can only use 120vac for now.

Richard

Website

Website

LtBadd wrote:Looks good, if at some time you want more information Diamond Ground Products has a tungsten guidebook that is a good read. That is, at least as far as tungsten CAN be a good read, well it is good information anyway.infernoST wrote:Sorry for the crappy photo, It is ground longitudinal, I'm going to try laying beads on mild steel until i get the feel for it then try aluminum. I should be picking up my Argon tomorrow and the 220 line should be done by next weekend. I can only use 120vac for now.

Thanks for the link, damn near passed out seeing those prices.WOW.

Keith

- MinnesotaDave

-

Weldmonger

-

Posts:

-

Joined:Sun Oct 27, 2013 10:57 pm

-

Location:Big Lake/Monticello MN, U.S.A.

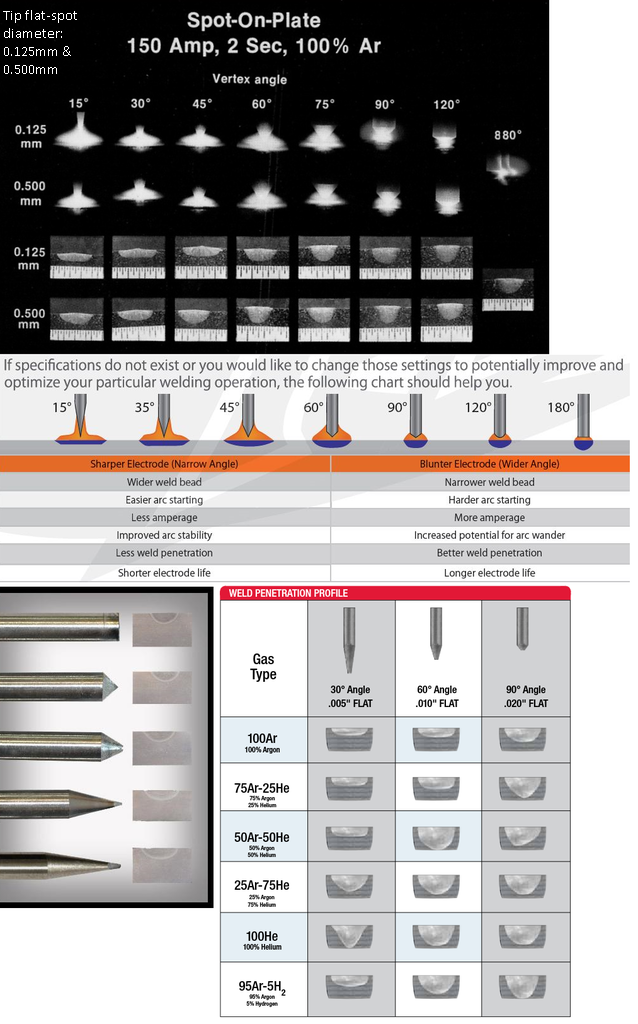

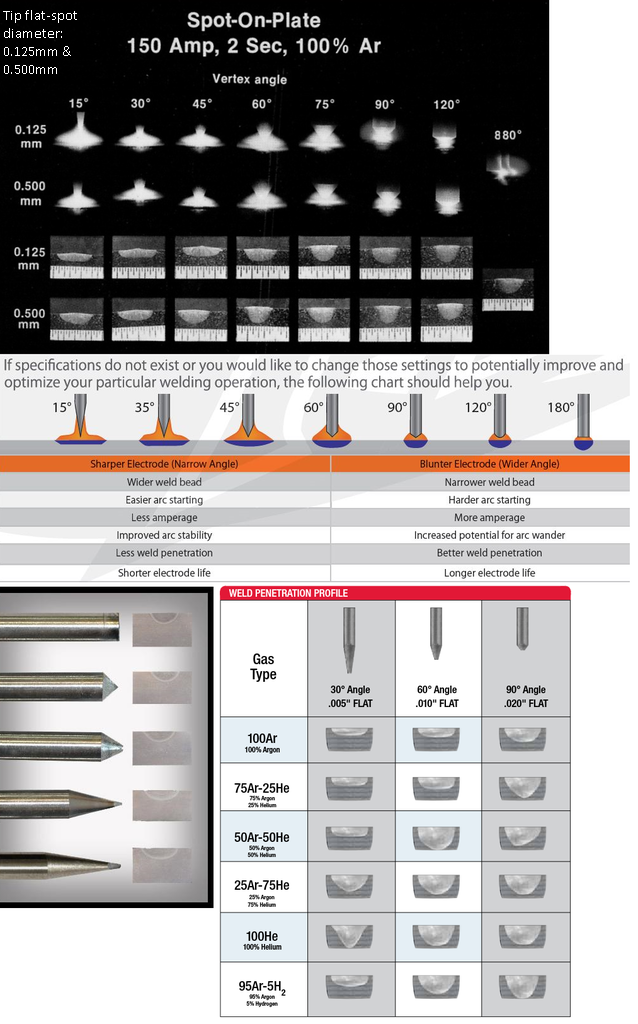

Here is some grinding information - might help you out if you don't already know this stuff.

Also, in general, with a given grind angle, the larger the flat spot ground on the tip, the more penetration.

That's what the 2nd pic is showing with the 0.125mm and 0.500mm slides.

Also, in general, with a given grind angle, the larger the flat spot ground on the tip, the more penetration.

That's what the 2nd pic is showing with the 0.125mm and 0.500mm slides.

- image.jpg (29.9 KiB) Viewed 1601 times

- spot on plate.jpg (36.78 KiB) Viewed 1601 times

- image3.jpg (32.81 KiB) Viewed 1601 times

Dave J.

Beware of false knowledge; it is more dangerous than ignorance. ~George Bernard Shaw~

Syncro 350

Invertec v250-s

Thermal Arc 161 and 300

MM210

Dialarc

Tried being normal once, didn't take....I think it was a Tuesday.

Beware of false knowledge; it is more dangerous than ignorance. ~George Bernard Shaw~

Syncro 350

Invertec v250-s

Thermal Arc 161 and 300

MM210

Dialarc

Tried being normal once, didn't take....I think it was a Tuesday.

Dave, thanks for the info. I copied it to my hard drive.MinnesotaDave wrote:Here is some grinding information - might help you out if you don't already know this stuff.

Also, in general, with a given grind angle, the larger the flat spot ground on the tip, the more penetration.

That's what the 2nd pic is showing with the 0.125mm and 0.500mm slides.

image.jpgspot on plate.jpgimage3.jpg

Keith

Photo taking HINT: when taking pics and you can't get the camera to focus because the object is too close, place something behind the object of interest. Take a look at this (showing off my awesome tungsten sharpening skills as well  )

)

Dave, I have combined those tungsten sharpening angle depictions into one picture, so that way you don't have to post several, just save this one, and it has all of them:

Dave, I have combined those tungsten sharpening angle depictions into one picture, so that way you don't have to post several, just save this one, and it has all of them:

Believe it or not, I use one of these:infernoST wrote:That is insane. What do you use to sharpen your tungstens?

It's all about technique. Good vision, steady hands, nimble finger dexterity, and a little bit of OCD.

- LtBadd

-

Weldmonger

-

Posts:

-

Joined:Sun Apr 12, 2015 4:00 pm

-

Location:Clearwater FL

-

Contact:

Gotta give credit where credit is due. I owe it to Jody and one of his videos, where he actually demonstrates how a tungsten that is slightly polished with a maroon scotchbrite pad can provide favorable results if you are welding near the bottom-end of that diameter tungsten's amperage range. You can get crisper arc starts and less arc-wander from doing so. Well I tried the same, and liked the results but wondered if there was an easier, quicker way to polish off the grinding lines left from grinding wheels on the tungsten tip that doesn't involve a few hundred manual "swipes" of scotchbrite pad. Of course it hit me: power tools. They simplify/accelerate most any kind of polishing, the same way a motorized grinding wheel quickly sharpens the tungsten in the first place. So I thought to myself: how can I use a rotary surface to polish it out? I look over and there it was; I just took it to another level. The rest is history.LtBadd wrote:The force is strong with this one...Oscar wrote:Believe it or not, I use one of these:infernoST wrote:That is insane. What do you use to sharpen your tungstens?

It's all about technique. Good vision, steady hands, nimble finger dexterity, and a little bit of OCD.

- LtBadd

-

Weldmonger

-

Posts:

-

Joined:Sun Apr 12, 2015 4:00 pm

-

Location:Clearwater FL

-

Contact:

Oscar, care to provide a pic of your setup with the model/brand name of the unit? I know there are different grades of SB, which do you use? Maybe when you have time a short video would be helpful for anyone who hasn't done this.Oscar wrote:[

Of course it hit me: power tools. They simplify/accelerate most any kind of polishing, the same way a motorized grinding wheel quickly sharpens the tungsten in the first place. So I thought to myself: how can I use a rotary surface to polish it out? I look over and there it was; I just took it to another level. The rest is history.

Richard

Website

Website

I didn't end up using ScotchBrite pads because they take too long to manually swipe the tungsten. I use the Harbor Freight Mini Grinder that I posted. Unless I need to grind a lot of material, such as first-time dressing a 1/8" tungsten, I use the orange grinding wheel to sharpen up the tungstens. Then I hold the tungsten upside-down on the polishing wheel so the wheel surface goes away from the tip, not into it, otherwise the tip will catch and you'll have a tungsten rod piercing in the palm of your hand. It polishes the tungsten very quickly @ 10,000 RPMs. Angle a few degrees left, a few right, then right down the middle, all while constantly rotating it with your fingertips, and you have one awesome polished tip.. You can even polish out an old, dull, dingy tungsten rod if you're steady enough. Ends up looking like new. I'll see what I can do about making a short clip.LtBadd wrote:Oscar, care to provide a pic of your setup with the model/brand name of the unit? I know there are different grades of SB, which do you use? Maybe when you have time a short video would be helpful for anyone who hasn't done this.Oscar wrote:[

Of course it hit me: power tools. They simplify/accelerate most any kind of polishing, the same way a motorized grinding wheel quickly sharpens the tungsten in the first place. So I thought to myself: how can I use a rotary surface to polish it out? I look over and there it was; I just took it to another level. The rest is history.

Tom Osselton

- Tom Osselton

-

Workhorse

-

Posts:

-

Joined:Sat Aug 15, 2015 12:33 am

-

Location:Calgary Alberta

Believe it or not, I use one of these:Oscar wrote:infernoST wrote:That is insane. What do you use to sharpen your tungstens?

I saw one of those in the pawnshop superstore but they wanted $100.00 for it and I didn't see the flexable drive either.

noddybrian

- noddybrian

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 24, 2013 12:13 pm

Plus 1 ! I also have that grinder though it's from Aldi - I thought it's factory stones too soft so have fitted a fine diamond wheel & it works great - the grinder is so small & light I have it on a swing out arm fixed to my welding cart so it's always with the welder - the arm came out of a skip & I think it was meant to hold a monitor or some sort of medical scanner display as all the stuff was from a hospital - now I don't have to walk far every time I contaminate the tungsten !

Return to “Welding Forum General Shop Talk”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities