Hi, Billy,

Much of what I do requires TIG under the WPS, but not pulse. It's on my wish-list, though.

Our MIg work doesn't even fall under a particular code. I want to change that.

There's a page, "Instructions", that's specific to posting a pic. If you have trouble, let me know.

Steve S

Comments & questions on new & past videos

- Otto Nobedder

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 06, 2011 11:40 pm

-

Location:Near New Orleans

I worked for a company called centeury heating making would burning stoves.This was before i worked at GE and we did the stack of dimes look all the time. There are some different things in our setup then in these threads. We used .45 wire vert down with a step pause motion like said before. We used a different gas which was a low argon hi co2 mix. This made it only possible in vert down horizontal and flat no vert up. I wish i had some picks to show you beacuse these welds lookd like high end stainless tig welds. the machines we used were mostly old canox mig welders and miller xmt304 inverters

Otto Nobedder, sounds like what I do, with high voltage, move forward, then back into the puddle to let it fill, move forward to where the leading edge of puddle will be when it fills, then back half a puddle till it fills and repeat....20 to 21 volts, wire feed 230 ipm with .035 70-s6, ar/co2 75/25 or ar/co2 92/8..hope this makes sense, maybe not quite as tiggy as your.....PRB

- Attachments

-

- tig like mig.jpg (52.76 KiB) Viewed 2863 times

Synchrowave 250,Dynasty 200 DX,Millermatic 250MP,Hypertherm Max43,Bobcat 225NT,Ellis Band Saw,Bridgeport Mill,Clausing 14" Lathe,16" Black & Decker Radial Armsaw,Hammers

James, pulsed mig will not look anything like tig, as it is pulsing in the hundreds of time per second range.....my experience with it is it is not really pretty....

Miller 60M feeder and Miller 452, at least this was my experience....PRB

Miller 60M feeder and Miller 452, at least this was my experience....PRB

Synchrowave 250,Dynasty 200 DX,Millermatic 250MP,Hypertherm Max43,Bobcat 225NT,Ellis Band Saw,Bridgeport Mill,Clausing 14" Lathe,16" Black & Decker Radial Armsaw,Hammers

- weldin mike 27

-

Weldmonger

-

Posts:

-

Joined:Fri Apr 01, 2011 10:59 pm

-

Location:Australia; Victoria

Hey,

I had a crack at this at work today, I had my machine set at the lowest of my range of settings 22 volts. It seems that that is still to hot to produce any real ripple in the weld. Any who, I use a flick forward and back when i cannot get a favourable gun angle that would see too much metal forced into the root of the joint causing overroll. Flick forward into the very root of the weld and then back up onto the pool to build the weld. Its not mig like tig buts it the biggest maneuver i do.

We do what we call "stop start" where a spot of weld is layed let go of the trigger move to the front of the nugget and spot again. So on and so forth. Not seen as particularly the right thing to do but its a good way to weld a small area of a big part that cannot be rotated and has changes of angles in a small area. The main point is that the gun is only moved the arc is off.

On a side note, here is some info on the new welders we are trialling for our new prototype vehicles that have a cro mo pipe sub frame with lots of cut outs and scallops and brackets.

http://www.ewm-group.com/en/ewmprodukte ... egory_id=8

I dont get to use them though.....

Mick

I had a crack at this at work today, I had my machine set at the lowest of my range of settings 22 volts. It seems that that is still to hot to produce any real ripple in the weld. Any who, I use a flick forward and back when i cannot get a favourable gun angle that would see too much metal forced into the root of the joint causing overroll. Flick forward into the very root of the weld and then back up onto the pool to build the weld. Its not mig like tig buts it the biggest maneuver i do.

We do what we call "stop start" where a spot of weld is layed let go of the trigger move to the front of the nugget and spot again. So on and so forth. Not seen as particularly the right thing to do but its a good way to weld a small area of a big part that cannot be rotated and has changes of angles in a small area. The main point is that the gun is only moved the arc is off.

On a side note, here is some info on the new welders we are trialling for our new prototype vehicles that have a cro mo pipe sub frame with lots of cut outs and scallops and brackets.

http://www.ewm-group.com/en/ewmprodukte ... egory_id=8

I dont get to use them though.....

Mick

echosixmike

- echosixmike

-

Workhorse

-

Posts:

-

Joined:Wed Feb 13, 2013 8:03 am

Pulse MIG, at least on my PowerMIG300(I guess it's a 350 since I updated the software) is to force the unit into spray arc at short circuit heat levels. It's multipulse per second. S/F....Ken M

Red: PowerMIG 300, Square Wave 175

Blue: DEL200, Syncro250, XMT300

Green: STH160

Black: Tweco 181i Fabricator

Oddball: Craftsman HF unit

Blue: DEL200, Syncro250, XMT300

Green: STH160

Black: Tweco 181i Fabricator

Oddball: Craftsman HF unit

I have also been able to get that appearance by exaggerating a weave of the gun. Mick you are probably set up to run too hot. I know that the appearance changes a lot when you pass 22-23 volts. Come to think of it I see the mig like tig pattern more often when I am using my dads Lincoln sp125 110v welder not my 12vs. Hmmm

Be the monkey....

Hey everyone....

Hopefully I can dispel some of the myths and assumptions about this technique.

For starters, it's just a technique. Much like walking the cup with TIG or using a lay-rod instead of a dip-move-dip...it's just a technique. I'm not saying that it's the best technique and it shouldn't be used in every situation. It is something that I have worked on for about 15 years and have had great success in using where it is appropriate, mainly in the Motorsports industry.

It is used in Short Circuit transfer mode, continuous welding. No "triggering", pulsing, or spot timers are used. The two main machines I have at my shop are my Lincoln PowerMIG 200 and a Lincoln SP135 Plus.

I use ER70S-6 wire in .023" in the SP135 and .030" in the PowerMIG 200. I use C25 gas at about 18-20cfh.

I religiously clean my materials and spend as much time as it takes to get a perfect fit-up.

Yes, I typically run lower setting on the machines than what is called for but I also run a much slower hand speed to accommodate it. No, it is not as fast as cranking up the machine and blowing in a bunch of weld but that is not my goal. It is still much faster than TIG and allows for a nice looking, sound weld with almost no clean-up.

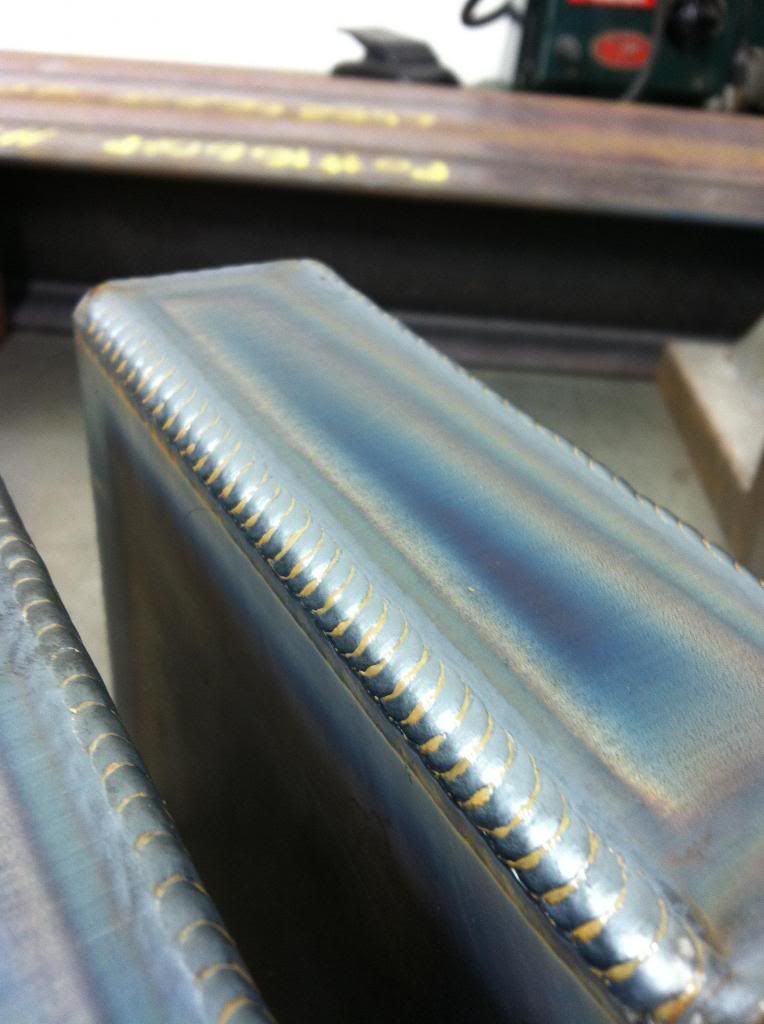

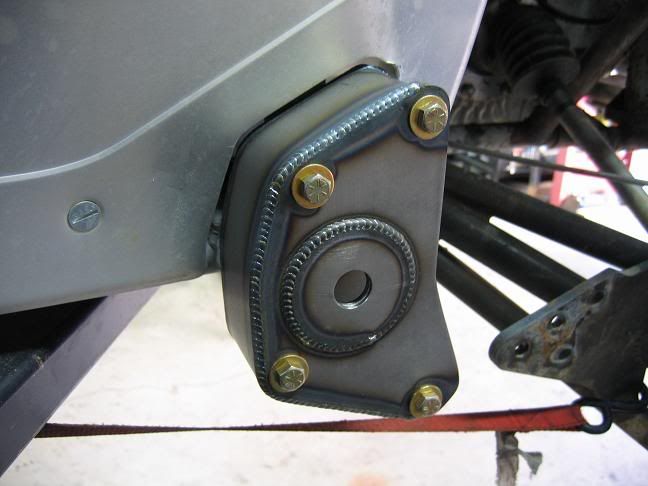

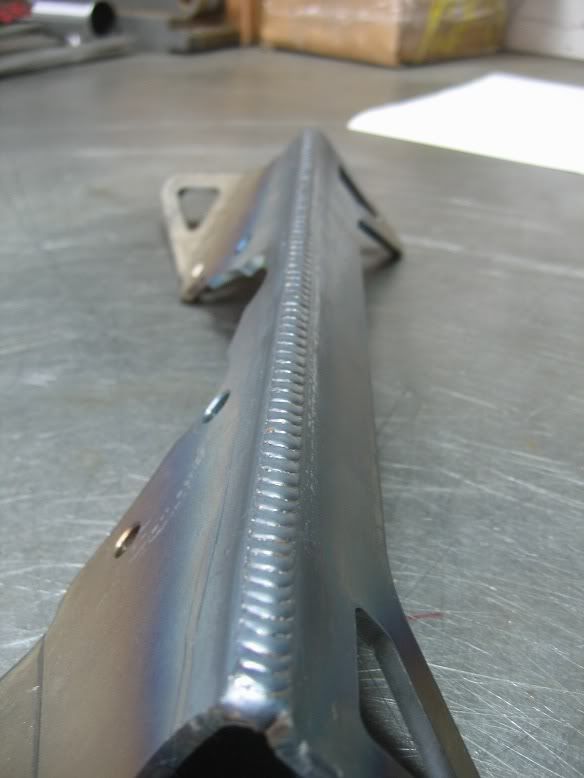

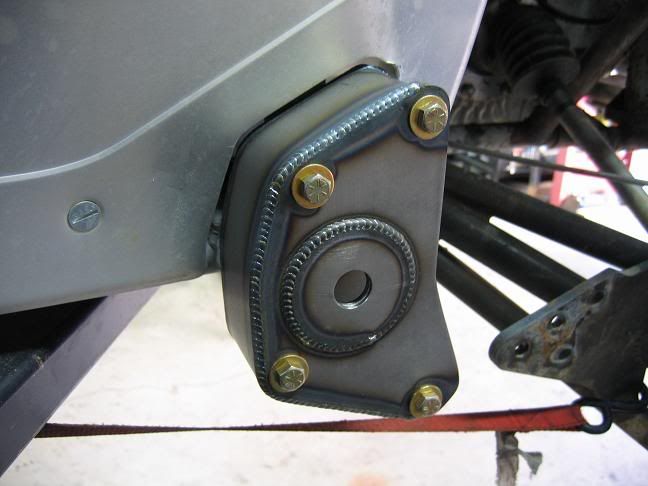

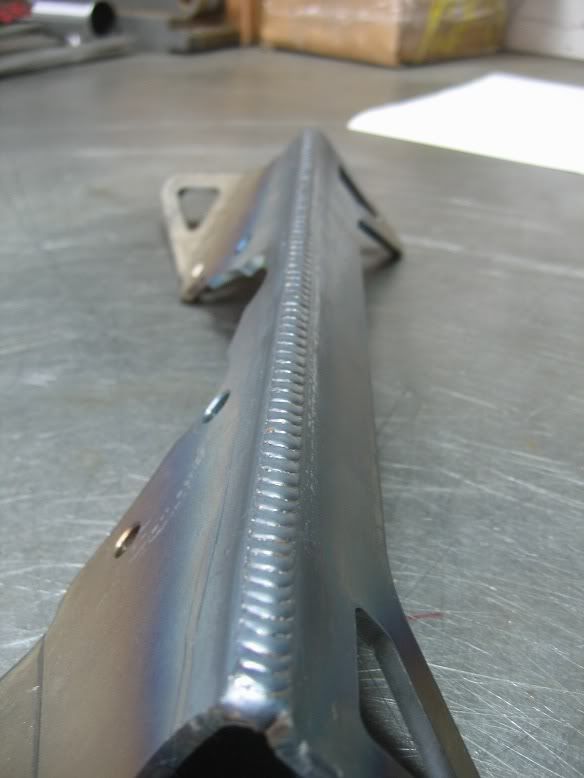

Here are a few pics of my welding and fabrication. These welds are untouched meaning no wiping, brushing, spraying, cleaning of any kind post weld.

Hopefully I can dispel some of the myths and assumptions about this technique.

For starters, it's just a technique. Much like walking the cup with TIG or using a lay-rod instead of a dip-move-dip...it's just a technique. I'm not saying that it's the best technique and it shouldn't be used in every situation. It is something that I have worked on for about 15 years and have had great success in using where it is appropriate, mainly in the Motorsports industry.

It is used in Short Circuit transfer mode, continuous welding. No "triggering", pulsing, or spot timers are used. The two main machines I have at my shop are my Lincoln PowerMIG 200 and a Lincoln SP135 Plus.

I use ER70S-6 wire in .023" in the SP135 and .030" in the PowerMIG 200. I use C25 gas at about 18-20cfh.

I religiously clean my materials and spend as much time as it takes to get a perfect fit-up.

Yes, I typically run lower setting on the machines than what is called for but I also run a much slower hand speed to accommodate it. No, it is not as fast as cranking up the machine and blowing in a bunch of weld but that is not my goal. It is still much faster than TIG and allows for a nice looking, sound weld with almost no clean-up.

Here are a few pics of my welding and fabrication. These welds are untouched meaning no wiping, brushing, spraying, cleaning of any kind post weld.

- weldin mike 27

-

Weldmonger

-

Posts:

-

Joined:Fri Apr 01, 2011 10:59 pm

-

Location:Australia; Victoria

Hey,

welcome to the forum. Thats lovely work. I have never migged with anything under .035 so that why i missed the piont a little.

Mick

welcome to the forum. Thats lovely work. I have never migged with anything under .035 so that why i missed the piont a little.

Mick

- Otto Nobedder

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 06, 2011 11:40 pm

-

Location:Near New Orleans

In ZTFab's pics,

(NICE work, BTW, especially keeping that level of consistency on tight radii!)

Note the color of the silicon "islands". This khaki color speaks to the prep work... That's as clean as you can weld carbon steel without working in a purge-box, which I've never heard of for MIG.

My clients do not hold me to such exacting standards, so I run hotter and faster, always .035 E70-s6. My favorite MIG machine at work (which everyone else hates) is an older Lincoln CV-305 with stand-alone wire feeder. I run 23.3V and 350 IPM, usually with Tri-mix. For 75/25, I back it down a bit.

I do not get the steps perfectly even at that speed. When precision is required it's TIGged. The MIG is for production,but I don't feel that should excuse sloppiness or inadequate welds, so I've worked my technique to the point any inspection of my MIG welds is selsom more than a glance.

Haven't seen Jody's "MIG like TIG" video yet... I'll have a look this eve.

Steve S

(NICE work, BTW, especially keeping that level of consistency on tight radii!)

Note the color of the silicon "islands". This khaki color speaks to the prep work... That's as clean as you can weld carbon steel without working in a purge-box, which I've never heard of for MIG.

My clients do not hold me to such exacting standards, so I run hotter and faster, always .035 E70-s6. My favorite MIG machine at work (which everyone else hates) is an older Lincoln CV-305 with stand-alone wire feeder. I run 23.3V and 350 IPM, usually with Tri-mix. For 75/25, I back it down a bit.

I do not get the steps perfectly even at that speed. When precision is required it's TIGged. The MIG is for production,but I don't feel that should excuse sloppiness or inadequate welds, so I've worked my technique to the point any inspection of my MIG welds is selsom more than a glance.

Haven't seen Jody's "MIG like TIG" video yet... I'll have a look this eve.

Steve S

Jody, I am probably the least experienced weldor here, but I've read the threads and I think I can interpret what ZTfab is telling us while not really telling us how he does that stack of dimes look. I haven't yet gone out to the shop and fired up but I have a sneaking suspicion that the technique is to jerk out of the puddle and pause. I watched your video and you are smooth as glass, as usual. Tracing the puddle, doing T's, E's or any other of what you normally refer to as "cursive" movements won't copy ZT's work, or any other. So, try jerking forward and pausing to make a new puddle half on and half off the previous one.

Now, I'm gonna go out there and give my theory a shot.

Now, I'm gonna go out there and give my theory a shot.

- Otto Nobedder

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 06, 2011 11:40 pm

-

Location:Near New Orleans

As would I, if that portion of the work were at my complete discretion. I get away with much, with little supervision, but my primary function is leak detection and ASME "R" stamp vessel repair. All TIG work, to code. When I rebuild auxillary structure, while it's still T&M work, it's on the "hurry-up" side of the job. I don't ever release a weld I'm not satisfied with, even on auxilliary structure, but I don't have time to turn it down and make it look perfect. It's a "function over form" thing with these clients.ZTFab wrote:Thanks guys.

Steve , my clients don't hold me to these standards. I hold myself to them.Otto Nobedder wrote:

My clients do not hold me to such exacting standards, so I run hotter and faster, always .035 E70-s6.

Steve S

rahtreelimbs

- rahtreelimbs

-

Heavy Hitter

-

Posts:

-

Joined:Mon Jun 14, 2010 10:39 pm

Just for schits and giggles I fooked around with the mig like tig a little tonight. I have a Lincoln SP-100 ( which was what I was using) and a Lincoln Pro Mig 180. I found that keeping the heat down a little and pausing in the puddle then moving out and repeating started to give me the tig look.

More experimenting to come!

More experimenting to come!

milt wrote:Jody, I am probably the least experienced weldor here, but I've read the threads and I think I can interpret what ZTfab is telling us while not really telling us how he does that stack of dimes look. I haven't yet gone out to the shop and fired up but I have a sneaking suspicion that the technique is to jerk out of the puddle and pause. I watched your video and you are smooth as glass, as usual. Tracing the puddle, doing T's, E's or any other of what you normally refer to as "cursive" movements won't copy ZT's work, or any other. So, try jerking forward and pausing to make a new puddle half on and half off the previous one.

Now, I'm gonna go out there and give my theory a shot.

Milt, you are incorrect. I have shared this method many times on many forums. It is a lower case cursive "e" type motion and I stay in the puddle, I do not whip forward and back.

I will never understand this "matter of fact" conjecture from people' who don't have first hand knowledge. Have an opinion, have a theory, but making "matter of fact statements" that aren't fact doesn't help anyone learn.

You said you read the threads but say that I'm not telling exactly how I achieve this look. That's blatantly false as I've outlined it multiple times, in explicit detail and have taught many people first hand.

Otto Nobedder wrote:

As would I, if that portion of the work were at my complete discretion. I get away with much, with little supervision, but my primary function is leak detection and ASME "R" stamp vessel repair. All TIG work, to code. When I rebuild auxillary structure, while it's still T&M work, it's on the "hurry-up" side of the job. I don't ever release a weld I'm not satisfied with, even on auxilliary structure, but I don't have time to turn it down and make it look perfect. It's a "function over form" thing with these clients.

Understandable. I wasn't insinuating that you would make a sub-standard weld.

That is also why I say that this technique has its place and applications.

I don't weld like this all of the time as each job has it requirements. Im currently building a 90ft long machine for a client that makes synthetic lifting slings and have MiG welded portions of it without this technique. In fact, most of my work for the last few years has been TIG. I do everything from custom copper parts to aluminum rigging components for Siemens wind power division.

- Otto Nobedder

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 06, 2011 11:40 pm

-

Location:Near New Orleans

ZTFab,

You will encounter all skill levels here, including "I just unpacked this thing... now what?"

It's a different environment from other dedicated sites for that reason... I've answered 6013 questions the same day as TIG on pipe questions.

I think it's a lot of fun!

You will encounter all skill levels here, including "I just unpacked this thing... now what?"

It's a different environment from other dedicated sites for that reason... I've answered 6013 questions the same day as TIG on pipe questions.

I think it's a lot of fun!

I don't doubt it, Steve.

It's the same thing on WeldingWeb where I have been a member for years and was a Moderator for some time.

Either way, newbie or old timer I will never understand some people's need to make false statements or assumptions about a situation, especially when the facts have been given. Is it an attempt to feel superior or smarter? I don't know but almost every time it happens they seem to include some caveat as if it precludes them from being wrong in the event they are called out.

I just wish more people would be open to learning and not be so afraid of new ideas/techniques.

It's the same thing on WeldingWeb where I have been a member for years and was a Moderator for some time.

Either way, newbie or old timer I will never understand some people's need to make false statements or assumptions about a situation, especially when the facts have been given. Is it an attempt to feel superior or smarter? I don't know but almost every time it happens they seem to include some caveat as if it precludes them from being wrong in the event they are called out.

I just wish more people would be open to learning and not be so afraid of new ideas/techniques.

- Otto Nobedder

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 06, 2011 11:40 pm

-

Location:Near New Orleans

I suppose some of the assumptions come from "That's what dad said".

Some come from very limited experience... Learning bad habits from lack of good examples.

Some, I suppose, come from "I know I'm right, 'cause I read it somewhere".

Some, from "I'm never friggin' wrong!"

I've been doing this thirty years and I still ask questions... I rarely assume someone is wrong unless I know better with certainty.

If I feel there's nothing left to learn, you might as well shoot me.

Some come from very limited experience... Learning bad habits from lack of good examples.

Some, I suppose, come from "I know I'm right, 'cause I read it somewhere".

Some, from "I'm never friggin' wrong!"

I've been doing this thirty years and I still ask questions... I rarely assume someone is wrong unless I know better with certainty.

If I feel there's nothing left to learn, you might as well shoot me.

BDoubleU

- BDoubleU

-

Workhorse

-

Posts:

-

Joined:Thu Jan 03, 2013 10:23 am

-

Contact:

ZT - thanks for sharing your technique and all the great pics!

weldfusion.com

Nice welds, ZTfab. It's obvious you like your job. It's the same way with aluminum TIG. If you come up with a certain pattern, someone thinks you cheated, even though it's obvious you are doing well enough to make a living at it. It's also the difference between custom work and production. In the custom world, it is not uncommon for fabricators to have signature welds.

Miller ABP 330, Syncrowave 250, Dynasty 300 DX.

Honorary member of the Fraternity of Faded Tee Shirts.

Honorary member of the Fraternity of Faded Tee Shirts.

Otto's looked well done too. MIG almost killed (literally) me in welding school. I remember a time when it was the smooth beads that looked cool. Like 7024 (Jet rod?) stick or smooth mig beads.

I wish I had a nickel for every time someone mentioned stack of dimes. That's the one term every old man that never welded knows. lol

I wish I had a nickel for every time someone mentioned stack of dimes. That's the one term every old man that never welded knows. lol

Miller ABP 330, Syncrowave 250, Dynasty 300 DX.

Honorary member of the Fraternity of Faded Tee Shirts.

Honorary member of the Fraternity of Faded Tee Shirts.

- weldin mike 27

-

Weldmonger

-

Posts:

-

Joined:Fri Apr 01, 2011 10:59 pm

-

Location:Australia; Victoria

Hey,

Speaking of smooth beads, we just got a new pallet of Lincoln ultra mag S6 wire at work. I dont know what the story is but it is way different to the previous pallet. Way way smoother with less silicon islands and really light grey. Like the lable is wrong.(s4 i nstead of s6) I told the WI he said that Lincoln China must have improved their processes. Not complaining though, it runs like a mad man.

Mick

Speaking of smooth beads, we just got a new pallet of Lincoln ultra mag S6 wire at work. I dont know what the story is but it is way different to the previous pallet. Way way smoother with less silicon islands and really light grey. Like the lable is wrong.(s4 i nstead of s6) I told the WI he said that Lincoln China must have improved their processes. Not complaining though, it runs like a mad man.

Mick

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities