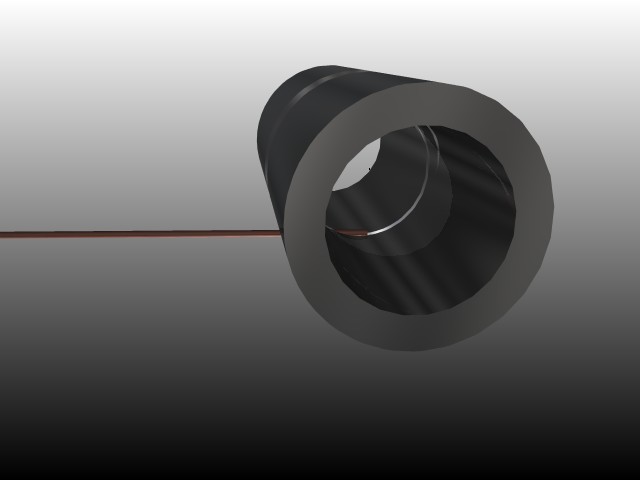

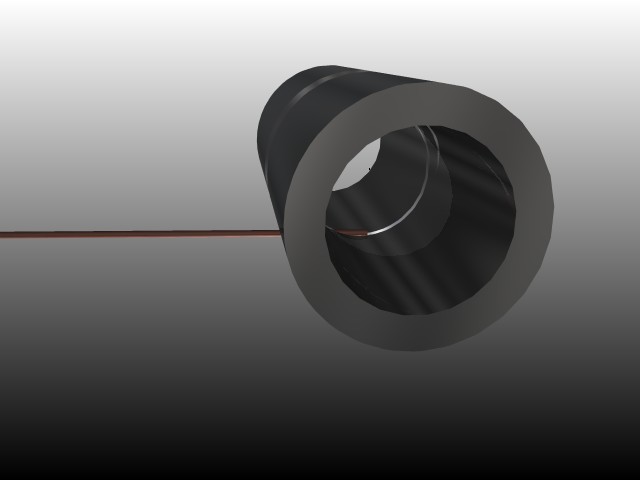

I basically use one or the other of these 2 techniques for open butt TIG pipe roots...

keyhole dip with 3/32" rod 1/8" gap...or laywire with 1/8" gap and wire

What technique/scheme do you use?

l941-76WB-g

Comments & questions on new & past videos

On larger gaps I will sometimes feed through the gap. It help me keep a little reinforcement on the ID if there is a condition that requires it. (Usually an inspector not aware of actual acceptance criteria). It also works sometimes tube welding where your partner may be in a bind.

I usually prefer keyhole. Never an IP problem. But sometimes suckback can be an issue.

I usually prefer keyhole. Never an IP problem. But sometimes suckback can be an issue.

Last edited by weldingt on Tue Jan 13, 2015 11:10 pm, edited 1 time in total.

Gerald Austin

If I didn't say it in the post- Have a great day !

Greeneville Tn

If I didn't say it in the post- Have a great day !

Greeneville Tn

- Superiorwelding

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 24, 2013 10:13 pm

-

Location:Eddy, TX

Jody,

The best tip I received in this video was the spot size to amperage. I need to make me a coupon to carry in my bag. Thank you very much!

-Jonathan

Edit. I got to thinking, if one makes a amperage same strip like Jody did in this video, wouldn't the circle be different sizes depending on the tungsten prep? Doesn't take away at all from what Jody was showing but if your tungsten on the test piece was needle sharp and you had a blunt on a weld test the circle might be a different size for the same amperage. Or am i totally off? Just a thought as I sit here at the library with my son at LEGO club with a room full of moms.

-Jonathan

The best tip I received in this video was the spot size to amperage. I need to make me a coupon to carry in my bag. Thank you very much!

-Jonathan

Edit. I got to thinking, if one makes a amperage same strip like Jody did in this video, wouldn't the circle be different sizes depending on the tungsten prep? Doesn't take away at all from what Jody was showing but if your tungsten on the test piece was needle sharp and you had a blunt on a weld test the circle might be a different size for the same amperage. Or am i totally off? Just a thought as I sit here at the library with my son at LEGO club with a room full of moms.

-Jonathan

Instagram- @superiorwelding/@learntotig

Twitter- @_JonathanLewis

https://www.learntotig.com

https://www.superiorweldandfab.com

https://www.youtube.com/+SuperiorWeldin ... ATHANLEWIS

Twitter- @_JonathanLewis

https://www.learntotig.com

https://www.superiorweldandfab.com

https://www.youtube.com/+SuperiorWeldin ... ATHANLEWIS

Jody,

I have a preference for using your lay-wire method after seeing your utube and giving it ago. No pipe welder over here in Oz seems to know about this method. I find it fast and very reliable as long as you get good fit ups as you have said previously. Also keeping the prep angle closer to 30 degrees there is less filling to do making it a faster joint to complete. Its all about time.

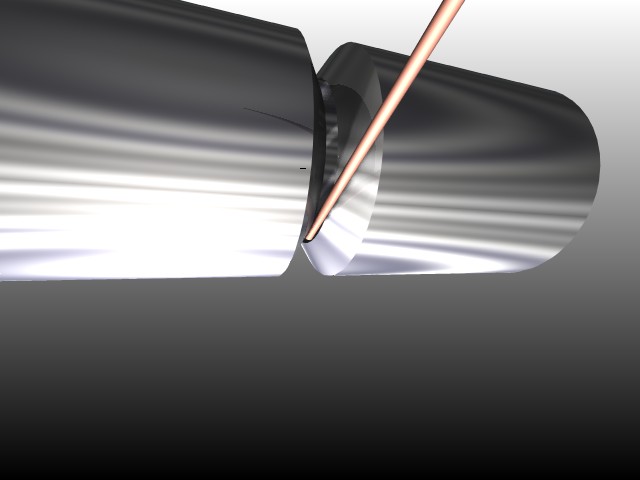

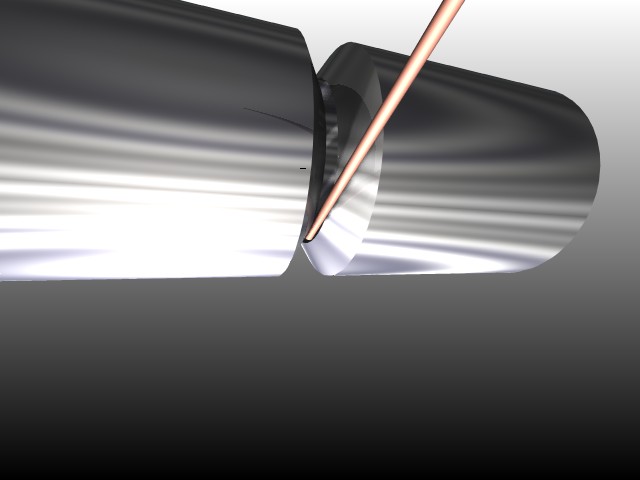

Sometimes on site you can't get good fit-ups because you can't get the grinder round the pipe properly because something is in the way or a pipe is slightly out of angular alignment that can't be moved. In these cases I use a different method:

Gap to be slightly wider than your wire so it can fall through easily, knife edge, bevel angle as per your preference. Hold the wire flat as you would for lay-wire and wiggle the arc. On the bottom of the pipe you hold the wire so it is mostly inside the pipe, up the sides hold the wire so it is half in and half out (knife edge prep is centre line of wire) and on top of the pipe hold the wire so the underside of the wire is flush with the inside of the pipe. This method counteracts the effects of gravity and gives a nice even finish once you get good at it. If the gap is too wide you just move the wire side to side with the arc but keeping the wire in the puddle at all times and if a keyhole opens up you push wire into it to close it up. Amps are about 5amps less than used for lay-wire.

It's a faster method than keyhole/dip (which I never use) but you can get needles forming inside the pipe until you become proficient at this method.

Incidentally, here in Oz (or at least in Queensland), 1/8" wire is almost never used. You can't go to your LWS and buy it. It is available but has to be ordered in. I myself have never seen 1/8" er70 wire before and never heard of it being used by anyone. I have asked a few journeyman pipe welders that work all over who say the same thing.

So these guys knock the flux off a 1/8" welding rod, bend it and use it to gap their butt preps which gives them a tight 1/8" prep and weld out with 3/32" wire. Cup walkers also like this method too.

I'd be interested for you to try it and comment.

Cheers,

Vic.

I have a preference for using your lay-wire method after seeing your utube and giving it ago. No pipe welder over here in Oz seems to know about this method. I find it fast and very reliable as long as you get good fit ups as you have said previously. Also keeping the prep angle closer to 30 degrees there is less filling to do making it a faster joint to complete. Its all about time.

Sometimes on site you can't get good fit-ups because you can't get the grinder round the pipe properly because something is in the way or a pipe is slightly out of angular alignment that can't be moved. In these cases I use a different method:

Gap to be slightly wider than your wire so it can fall through easily, knife edge, bevel angle as per your preference. Hold the wire flat as you would for lay-wire and wiggle the arc. On the bottom of the pipe you hold the wire so it is mostly inside the pipe, up the sides hold the wire so it is half in and half out (knife edge prep is centre line of wire) and on top of the pipe hold the wire so the underside of the wire is flush with the inside of the pipe. This method counteracts the effects of gravity and gives a nice even finish once you get good at it. If the gap is too wide you just move the wire side to side with the arc but keeping the wire in the puddle at all times and if a keyhole opens up you push wire into it to close it up. Amps are about 5amps less than used for lay-wire.

It's a faster method than keyhole/dip (which I never use) but you can get needles forming inside the pipe until you become proficient at this method.

Incidentally, here in Oz (or at least in Queensland), 1/8" wire is almost never used. You can't go to your LWS and buy it. It is available but has to be ordered in. I myself have never seen 1/8" er70 wire before and never heard of it being used by anyone. I have asked a few journeyman pipe welders that work all over who say the same thing.

So these guys knock the flux off a 1/8" welding rod, bend it and use it to gap their butt preps which gives them a tight 1/8" prep and weld out with 3/32" wire. Cup walkers also like this method too.

I'd be interested for you to try it and comment.

Cheers,

Vic.

Flat out like a lizard drinkin'

Over here most welders feed through the gap or dip.

Most common wire is 2.4mm (3/32) (or smaller for thin material) with very few exceptions and most welders walk the cup (personally for pipes up to 3" I prefer to freehand the root and only walk the cup on the cap).

I have seen a couple of welders use 3.2mm (1/8) rod but it is mostly on bigger diameters welding very hot but also very fast.

Another difference is that most common TIG rod for mild carbon steel is ER70S-6 and not -2 or -3.

The first time I saw the forward and back technique was on your videos so I tried it with 2.4mm rod and 2.4mm gap and guess what? I like it a lot as it is fast and gives a very uniform root with enough reinforcement. That is on carbon steel pipe though and I have never tried it on stainless where I always dip.

Of course in the field you have to be able to use all the other techniques since fit up can be far from perfect.

Most common wire is 2.4mm (3/32) (or smaller for thin material) with very few exceptions and most welders walk the cup (personally for pipes up to 3" I prefer to freehand the root and only walk the cup on the cap).

I have seen a couple of welders use 3.2mm (1/8) rod but it is mostly on bigger diameters welding very hot but also very fast.

Another difference is that most common TIG rod for mild carbon steel is ER70S-6 and not -2 or -3.

The first time I saw the forward and back technique was on your videos so I tried it with 2.4mm rod and 2.4mm gap and guess what? I like it a lot as it is fast and gives a very uniform root with enough reinforcement. That is on carbon steel pipe though and I have never tried it on stainless where I always dip.

Of course in the field you have to be able to use all the other techniques since fit up can be far from perfect.

- MinnesotaDave

-

Weldmonger

-

Posts:

-

Joined:Sun Oct 27, 2013 10:57 pm

-

Location:Big Lake/Monticello MN, U.S.A.

In my opinion you are correct Jonathan - based on these spot-on-plate testing results:Superiorwelding wrote:Jody,

The best tip I received in this video was the spot size to amperage. I need to make me a coupon to carry in my bag. Thank you very much!

-Jonathan

Edit. I got to thinking, if one makes a amperage same strip like Jody did in this video, wouldn't the circle be different sizes depending on the tungsten prep? Doesn't take away at all from what Jody was showing but if your tungsten on the test piece was needle sharp and you had a blunt on a weld test the circle might be a different size for the same amperage. Or am i totally off? Just a thought as I sit here at the library with my son at LEGO club with a room full of moms.

-Jonathan

- image2.jpg (36.78 KiB) Viewed 2622 times

Dave J.

Beware of false knowledge; it is more dangerous than ignorance. ~George Bernard Shaw~

Syncro 350

Invertec v250-s

Thermal Arc 161 and 300

MM210

Dialarc

Tried being normal once, didn't take....I think it was a Tuesday.

Beware of false knowledge; it is more dangerous than ignorance. ~George Bernard Shaw~

Syncro 350

Invertec v250-s

Thermal Arc 161 and 300

MM210

Dialarc

Tried being normal once, didn't take....I think it was a Tuesday.

- weldin mike 27

-

Weldmonger

-

Posts:

-

Joined:Fri Apr 01, 2011 10:59 pm

-

Location:Australia; Victoria

Of course, as you are trying to find an unknown variable, you would make sure that the ones you can control are spot on. Being flow rate, cup size, stick out and electrode prep. No point doing the test if anything else is different.

Here is one of several Fieldres has made on welding through the gap. He is actually wearing a hood in this one. http://youtu.be/IYVC65XT2l4

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities