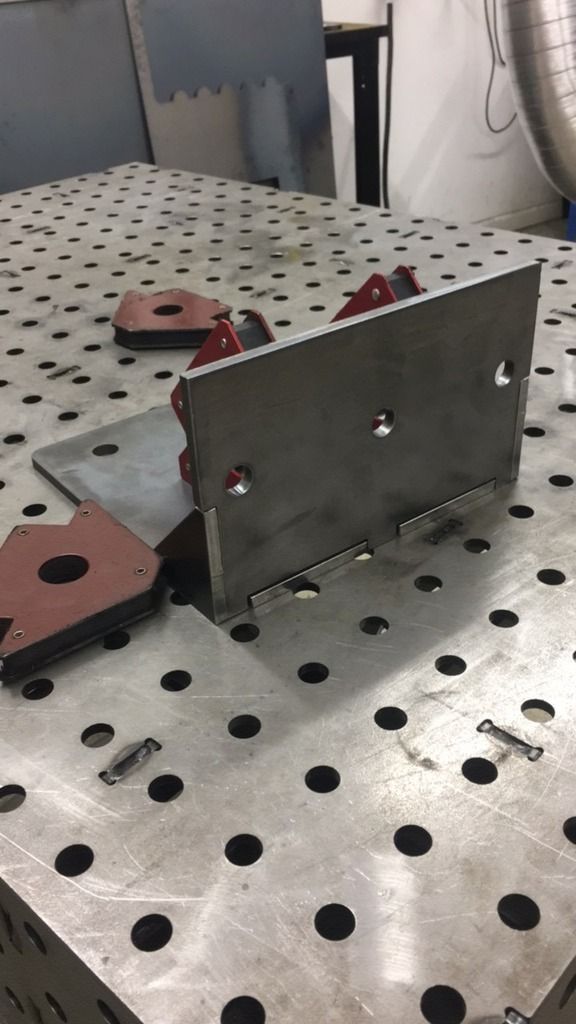

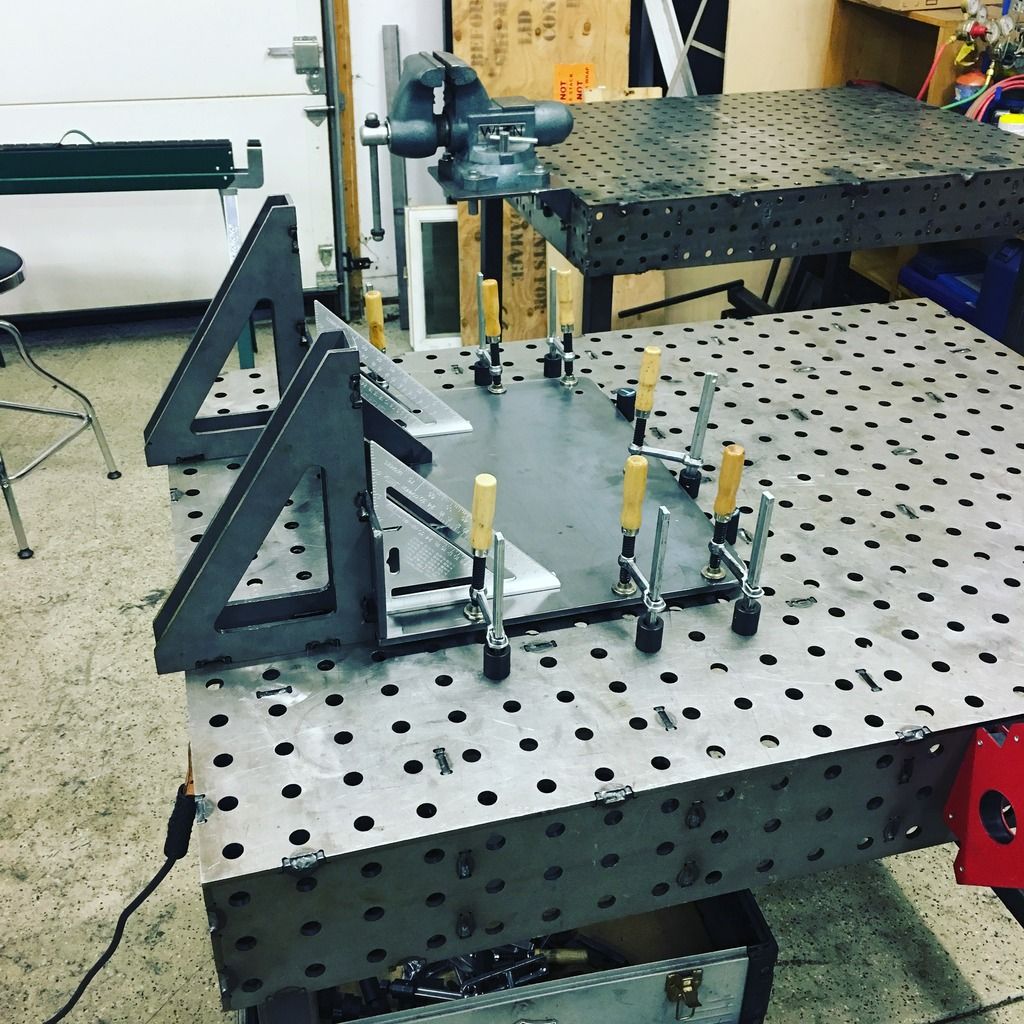

I've had two 36" x 48" fabBlock fixturing tables for about six months now. The tables are a great value and are extremely versatile. I use one for most of my general welding and fixturing; The other is a workstation that holds my vice, chop saw, and more tools are soon to come. Using Fusion 360, I have designed and fabricated a series of adaptors to mount the tools mentioned above.

I am creating this thread because I'm curious to hear about other's experiences with the tab and slot tables.

Here are some pictures of the mounts I've fabricated.