I'm joining two gangways togheter, 4 meters long and about 120kg each part.

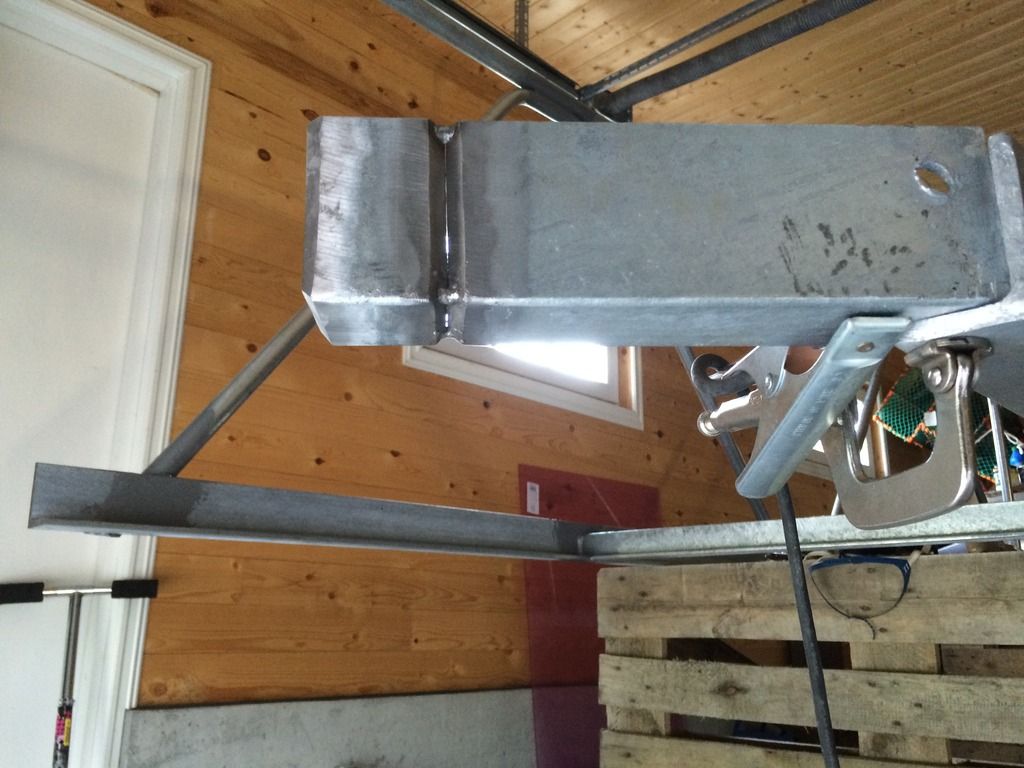

Here's a practice joint i prepped:

The steel is 8mm thick, and i've grinded a bevel leaving about 0,5 - 1mm steel. I have to weld it overhead and vertical up.

I'm using a Kemppi Minarc 150 and NST 7016S 2.5mm rods.. For the first bead i would go about 75 amps, just hot enough to not make a hole midway.. Afterwards i'd put two beads side by side filling the bevel, about 80 amps..

What do you guys think?

And what should I do to avoid getting that "Void" or "Crater" at the end of my vertical up?