Jeff, I'd think by now my sense of humor and sense of fair play would have told you volumes about my past. I, too, have been through the wringer. Much of it by the foolish choices of youth, meaning my own damn fault. The stupid part is, I could have made it easy, scholarships and the like, if I'd just conformed.

Steve S

Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process

- Otto Nobedder

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 06, 2011 11:40 pm

-

Location:Near New Orleans

kiwi2wheels

- kiwi2wheels

-

Ace

-

Posts:

-

Joined:Sun Feb 17, 2013 10:27 am

This is from the follow on video from Jeff's Tube Notching link.

https://www.youtube.com/watch?v=EH2dAVmpPdo

https://www.amazon.com/AHP-AlphaTIG-Sti ... B00REX6USW

The Chinese at least seem to understand that a user friendly welder has knobs for adjustment, not accessing a ******* menu to change settings.

https://www.youtube.com/watch?v=EH2dAVmpPdo

https://www.amazon.com/AHP-AlphaTIG-Sti ... B00REX6USW

The Chinese at least seem to understand that a user friendly welder has knobs for adjustment, not accessing a ******* menu to change settings.

exnailpounder

- exnailpounder

-

Weldmonger

-

Posts:

-

Joined:Thu Dec 25, 2014 9:25 am

-

Location:near Chicago

Or maybe those knobs aren't hooked up and don't do anything and the Chinese sit back and read these forums about how to use the settings on their welders and laugh their asses offkiwi2wheels wrote:This is from the follow on video from Jeff's Tube Notching link.

https://www.youtube.com/watch?v=EH2dAVmpPdo

https://www.amazon.com/AHP-AlphaTIG-Sti ... B00REX6USW

The Chinese at least seem to understand that a user friendly welder has knobs for adjustment, not accessing a ******* menu to change settings.

Ifyoucantellmewhatthissaysiwillbuyyouabeer.

sedanman

- sedanman

-

Ace

-

Posts:

-

Joined:Sun Jan 03, 2016 2:54 pm

-

Location:Beacon and Pawling, New York

If the brand you are looking at is sold on Homedepot.com, I highly recommend buying it there and putting on a Home Depot card. You can get extended financing just by asking for it and you have ONE YEAR to return it for any reason. You can just change your mind and take it back.

flytyer232

- flytyer232

-

New Member

-

Posts:

-

Joined:Sun Mar 19, 2017 2:13 pm

-

Location:Minnesota

I have an AHP Alpha Tig 200x, and while i am very new to tig welding, it seams great so far. Just remember to buy the welder from an authorized dealer, as apparently there is factory seconds, and refurbished ones there on the market...

I bought mine on amazon, through the AHP store. Shipping was alot faster than they listed, only took 4 days....

https://www.amazon.com/gp/product/B00RE ... UTF8&psc=1

I bought mine on amazon, through the AHP store. Shipping was alot faster than they listed, only took 4 days....

https://www.amazon.com/gp/product/B00RE ... UTF8&psc=1

- weldin mike 27

-

Weldmonger

-

Posts:

-

Joined:Fri Apr 01, 2011 10:59 pm

-

Location:Australia; Victoria

Chinese are true spartans and minimalists when it comes to electronics, they put maximum minimum into stuff they export cheap. This is why their stuff dies often as it does not have durability reserve. When I studied electronics, and we had to design microchip logic schemes, our tutor told us, that if you are able to make your microchip cheaper for 1 cent than rival, it is a big gain, because some asian gonna make them millions, and that saved cent makes profit.

But in general, it is not a good idea fixing chinese stuff, our heavy duty welders have MOST brand (Polish(chinese I suspect)) welders, they die with marvelous regularity, old Lincoln Powertecs sometimes get out of order(just because nobody cleans a dust out of them), my work ESAB only once (when I was away).

But in general, it is not a good idea fixing chinese stuff, our heavy duty welders have MOST brand (Polish(chinese I suspect)) welders, they die with marvelous regularity, old Lincoln Powertecs sometimes get out of order(just because nobody cleans a dust out of them), my work ESAB only once (when I was away).

kiwi2wheels

- kiwi2wheels

-

Ace

-

Posts:

-

Joined:Sun Feb 17, 2013 10:27 am

You make an excellent point about the dust issue. Even with high $$$ TIG inverters ( EWM, ESS, Lorch ) I've noticed there is usually a difference between machines of the same model, depending on the age of the machine, the environment it's used in and if it's in a shop that care about maintenance, as opposed to fixing it when it dies.cherwolf wrote:Chinese are true spartans and minimalists when it comes to electronics, they put maximum minimum into stuff they export cheap. This is why their stuff dies often as it does not have durability reserve. When I studied electronics, and we had to design microchip logic schemes, our tutor told us, that if you are able to make your microchip cheaper for 1 cent than rival, it is a big gain, because some asian gonna make them millions, and that saved cent makes profit.

But in general, it is not a good idea fixing chinese stuff, our heavy duty welders have MOST brand (Polish(chinese I suspect)) welders, they die with marvelous regularity, old Lincoln Powertecs sometimes get out of order(just because nobody cleans a dust out of them), my work ESAB only once (when I was away).

kiwi2wheels

- kiwi2wheels

-

Ace

-

Posts:

-

Joined:Sun Feb 17, 2013 10:27 am

Jakedaawg

- Jakedaawg

-

Guide

-

Posts:

-

Joined:Mon Feb 16, 2015 8:45 pm

-

Location:Near Traverse City, Mi.

When it comes to perusing these off brand welder threads/discussions the above is the most well reasoned response I have read to date...Kudos to you, Clavius!!!clavius wrote:My take:

I don't think I would buy any new machine with the idea that I would alter the guts to improve it. I might do something like that in the case of a really inexpensive used machine, but I work on high power electrical/electronics stuff for a living.

When faced with decisions like this I ask myself what sort of project am I looking for. Do I want a welder to weld stuff with, or do I want a welder to "BE" the project? Either approach is valid, it just depends what you want.

I don't own any of these Chinese made machines so I do not either defend nor criticism them. What is undeniable is that there are many, many people out there that have bought them and are perfectly happy with them and they do offer a lot of bang-for-the-buck. There are a few factory support horror stories around on the web, but you can find those for Miller, Lincoln, ESAB, etc too, if you look around enough.

For myself, after much mental anguish, I went with the Lincoln SW200 from a local welding supply. That way there is a front store window that I can throw the machine through if the service is really, really bad...

Miller Dynasty 280 DX, Lincoln 210 MP, More tools than I have boxes for and a really messy shop.

My Esab`s manual requires cleaning once a year, but I do every few months, because an atmosphere in our factory is so dusty(plasma cutter is in the same building), I would not recommend blowing pressurized air into fan mesh or from outside in, while side covers are on. Plug out power, so none of electrones are in circuit. Take of side panels, and gently blow dust away from circuit boards, try to not blow them in transformer or other tight spaces, air should blow from side. It would be even safer to place your welder on dielectric mat(so no electrostatic electricity could damage your electronics), or just try to not touch electronic components with your hose, just air.Fly wrote:When you recommend cleaning, are you removing the cover & blowing it out with a air hose?

Fly

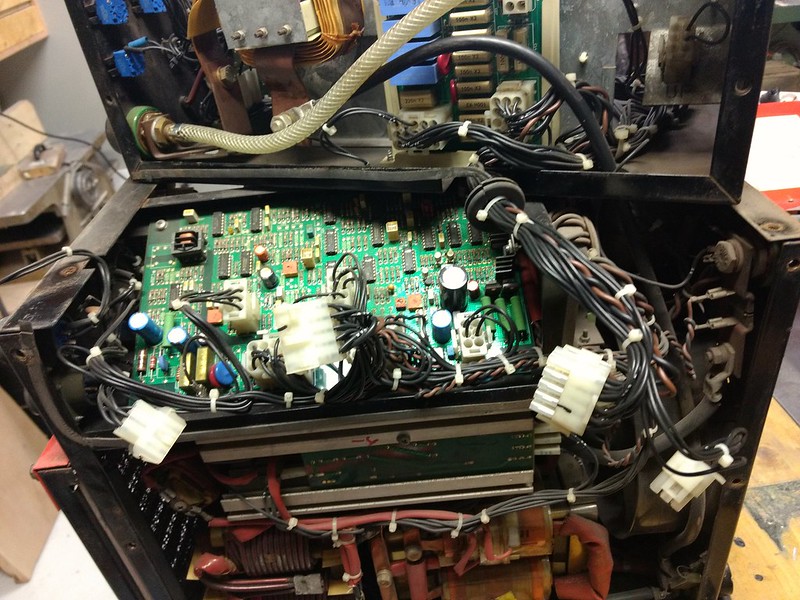

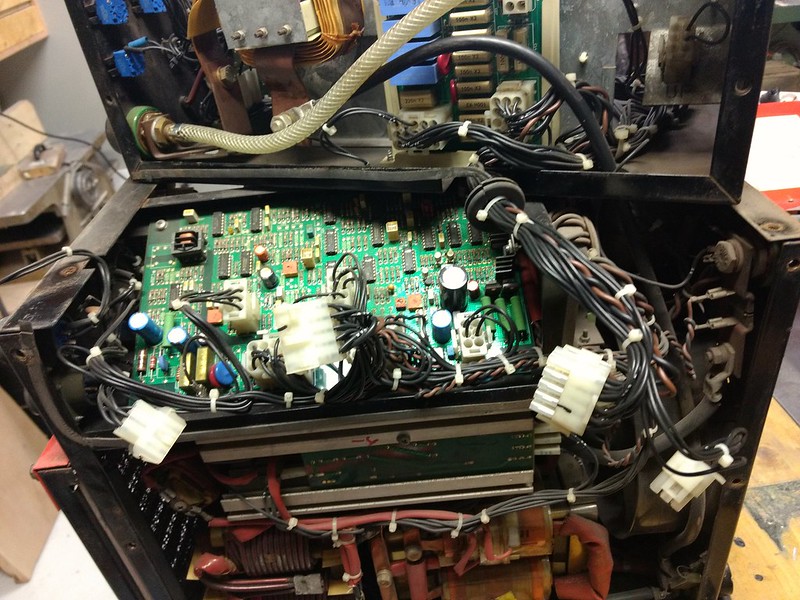

Hey speaking of electronics, while it's not worth repairing chinese welders, this old Kemppi of mine deserves better. Replaced all the Rifa capacitors in my welder, the old ones were degraded (cracks) and I believe this caused erratic arc, especially at lower currents.

I had to take the welder apart half way to get at the second board. But it was worth it, the arc now feels much nicer and more stable at low currents. All the electrolytic capacitors still look fine. Nice to have a welder you can service yourself. Pity there's no AC though...

I had to take the welder apart half way to get at the second board. But it was worth it, the arc now feels much nicer and more stable at low currents. All the electrolytic capacitors still look fine. Nice to have a welder you can service yourself. Pity there's no AC though...

- tungstendipper

-

Weldmonger

-

Posts:

-

Joined:Sun Nov 19, 2017 10:09 am

I've seen these pics before! Glad you shared them here.

Lincoln MP 210, Lincoln Square Wave 200,

Everlast 210 EXT

Thermal Dynamics 25 Plasma cutter

" Anything that carries your livelihood wants to be welded so that Thor can’t break it."

CJ737

Everlast 210 EXT

Thermal Dynamics 25 Plasma cutter

" Anything that carries your livelihood wants to be welded so that Thor can’t break it."

CJ737

And you know how to get results with a bit sandpapering of your ballsweldin mike 27 wrote:I got the job because I'm Australian. International timezones and all.

I bought a Kemppi Mastertig 10 years ago for probably too many doll-hairs, but it has been used almost every week since then and has never had it's skirt lifted

I'm also old enough to remember the days of the cheap and tinny Japanese stuff...? For many years the Chinese have had people of all nationalities setting up their manufacturing plants and what's coming out of those is improving all the time. This is, in part, unfortunate for Western manufacturing but a lesser burden on our personal bank balances.

- weldin mike 27

-

Weldmonger

-

Posts:

-

Joined:Fri Apr 01, 2011 10:59 pm

-

Location:Australia; Victoria

Your doll hairs were well spent. Kemppi equals gooderer. As for the cricket.... Those guys should have been banned for life and never heard from again. Can you imagine that outrage our oh so righteous people would have come up with if it was an Indian or Pakistani?

nomoreusmc

- nomoreusmc

-

New Member

-

Posts:

-

Joined:Tue Dec 29, 2015 10:40 pm

-

Location:Springfield, MO

I have 2 Everlast Tig machines and to be honest I think they're a better build quality than my 210mp and sw200. I have used an alphatig in the professional environment and the machine is Rock solid if you don't try to pull higher amps on 120v. I have opened all of them and the Everlast are nicer than the Lincoln and ahp is on par.

That being said, it kinda hurts my feelings a bit because I have always been a red guy. Both the Lincoln's have been in for warranty repair. Neither of the Everlast Tig machines I have have been in. Ymmv

Sent from my LGL84VL using Tapatalk

That being said, it kinda hurts my feelings a bit because I have always been a red guy. Both the Lincoln's have been in for warranty repair. Neither of the Everlast Tig machines I have have been in. Ymmv

Sent from my LGL84VL using Tapatalk

Return to “Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities