Orbital welders have to deal with problems like sulfur mismatch. Specially when autogenous welding is used. Mismatch can also be noticed by hand welding.

Mismatch will lift your puddle and it can affect to the penetration. Also undercut is usually present too. Sometimes welds will be rejected, so mismatch is not very nice thing to have around.

LnEwHEAyI40

mdT5qjtAqlI

Little bit of metallurgy too, just because I love it

Sulfur is impurity in steels. Usually steel makers try to get as low as possible, because it can affect to corrosion resistance for example. In the other hand on stainless steel sulfur tends to make machining easier. So sometimes it's ideal to have little bit of sulfur in the steel. That's why there is grades with higher sulfur content and those are usually called machining grades.

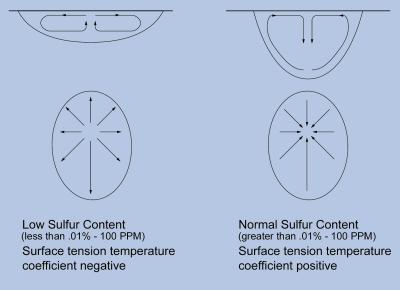

Sulfur will also affect to penetration of the weld, as it determines how metal will flow in the puddle. With very low sulfur contents it's sometimes very hard to get decent penetration without concavity etc.