I'm going through exactly the same here.

I'm smitten by my TIG set - and mines a "cheapo" £800 Rtech AC unit - almost the cheapest I could find ... I can't wait to try something expensive like a Miller, Lincoln or Kemmpi - in time, I can see myself upgrading to the Kemppi 2300.

I really like my trusty old MIG, but my TIG is pure joy to weld with.

I've used it in anger a few times now, mainly for welding in threaded lugs, and I am so impressed with it.

Especially the ability to "quick zap" it with a tack - brilliant.

But... The number 26 torch handle is really big,and long, with heavy inflexible cables.

It's hard work for long jobs.

I don't have big hands, and they aren't so strong ( I work everyday on a keyboard and fine electronics!) so I end up holding it close to the top, which isn't good practice.

I will only very rarely use the full power of my set, so I'll be getting a size 9 flexhead as soon as I can muster the funds.

I like the really idea of the really small size 9 that Jody shows on his video - ideal for 99% of my work.

Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process

Captainbeaky

- Captainbeaky

-

Workhorse

-

Posts:

-

Joined:Fri May 29, 2015 6:00 pm

-

Location:Madeira, Portugal

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

+1. Heck yes.Captainbeaky wrote:

I will only very rarely use the full power of my set, so I'll be getting a size 9 flexhead as soon as I can muster the funds.

I like the really idea of the really small size 9 that Jody shows on his video - ideal for 99% of my work.

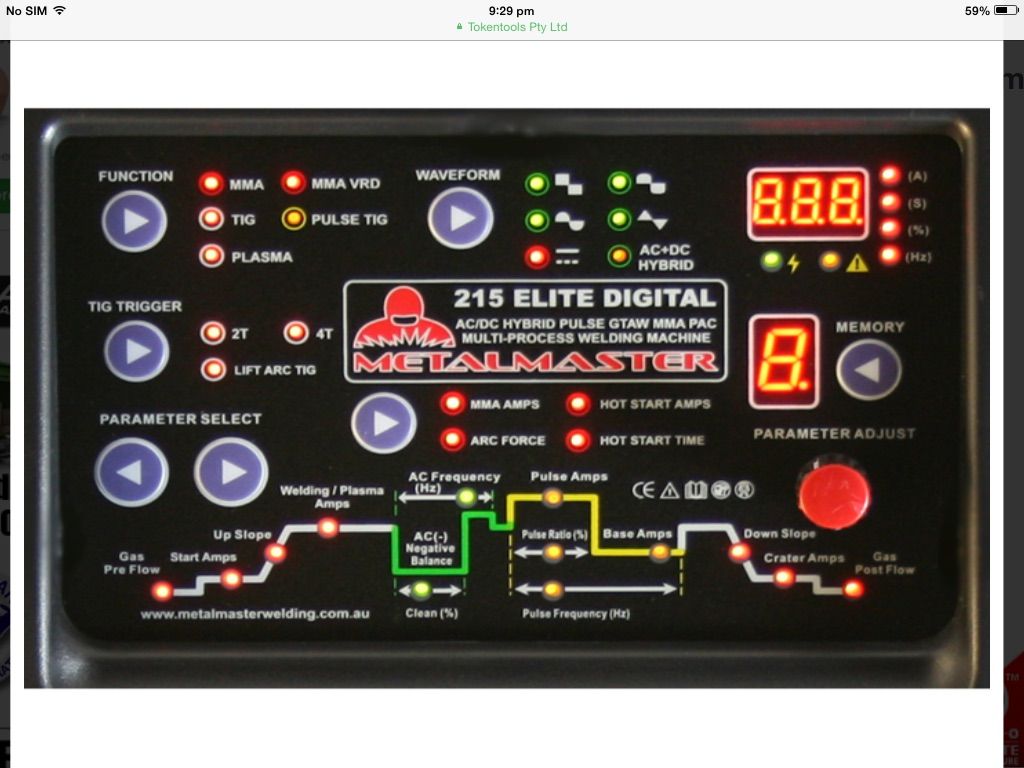

I'm crazy about my TIG too ($2,000-ish ACDC pulse + stick + plasma). But just the same, my work is pretty much all light duty, thin alloy or stainless...race motorcycles. A tiny #9 torch is going to be a joy.

Unlike you though, Captainbeaky, I think it will be a long while before I outgrow my machine. It's not exactly an expensive rig (by Australian standards) but it's a good 'un. Loving it.

Kym

Captainbeaky

- Captainbeaky

-

Workhorse

-

Posts:

-

Joined:Fri May 29, 2015 6:00 pm

-

Location:Madeira, Portugal

My Rtech AC/DC machine is pretty much the cheapest I could get that wasn't a Chinese generic machine.

It's definitely the cheapest IGBT machine in the UK , and is absolutely fine for my use at the moment.

It came highly reccomended as a starter AC TIg by a welder in Rolls-Royce aero engines.

The next machine in the reccomendations ( and on my list) was the Kemppi 2300, which is about £2300, before going up to the Miller Dynasty at over £4,000.

I'll see how I fare with the RTech for now, but I have a nagging suspicion that the 130 amp max might be a little too low for the heavier steelwork, and the higher power RTech machines get quite close to the price of the Kemppi.

But then again, the heavy work would be Steel, not ally, so I might be better off getting a 200 amp DC TIg, or upgrading the MIg to a multi purpose machine - we will see...

I did use a Kemppi MIG the other day - it was very nice indeed, really smooth and controllable.

Decisions decisions.....

It's definitely the cheapest IGBT machine in the UK , and is absolutely fine for my use at the moment.

It came highly reccomended as a starter AC TIg by a welder in Rolls-Royce aero engines.

The next machine in the reccomendations ( and on my list) was the Kemppi 2300, which is about £2300, before going up to the Miller Dynasty at over £4,000.

I'll see how I fare with the RTech for now, but I have a nagging suspicion that the 130 amp max might be a little too low for the heavier steelwork, and the higher power RTech machines get quite close to the price of the Kemppi.

But then again, the heavy work would be Steel, not ally, so I might be better off getting a 200 amp DC TIg, or upgrading the MIg to a multi purpose machine - we will see...

I did use a Kemppi MIG the other day - it was very nice indeed, really smooth and controllable.

Decisions decisions.....

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

This is my little rig. Maybe when I gain more experience I'll start picking faults with it but at the moment it's way better than I am. Smooth and very easy to use.

Mind you...connecting fencing wire to the terminals of an old car battery would be way better than I am. But every day is a school day.

Kym

Return to “Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities