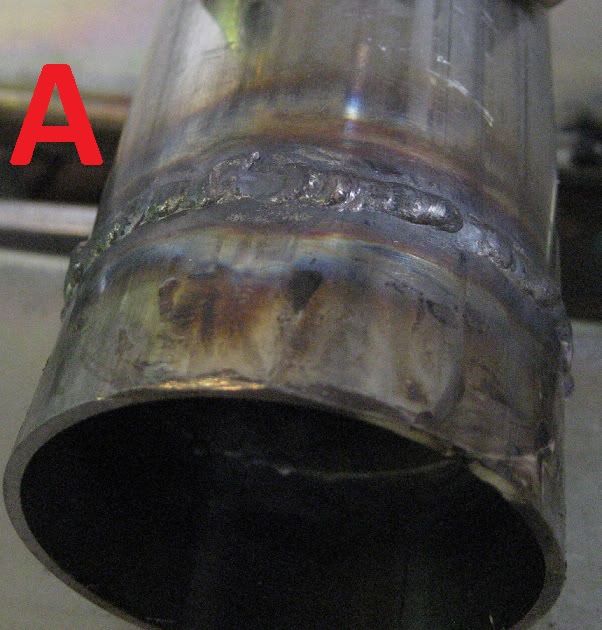

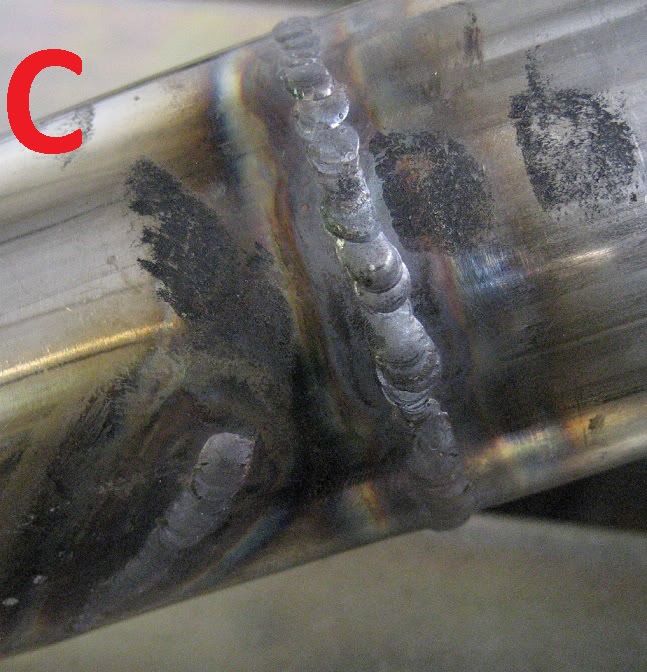

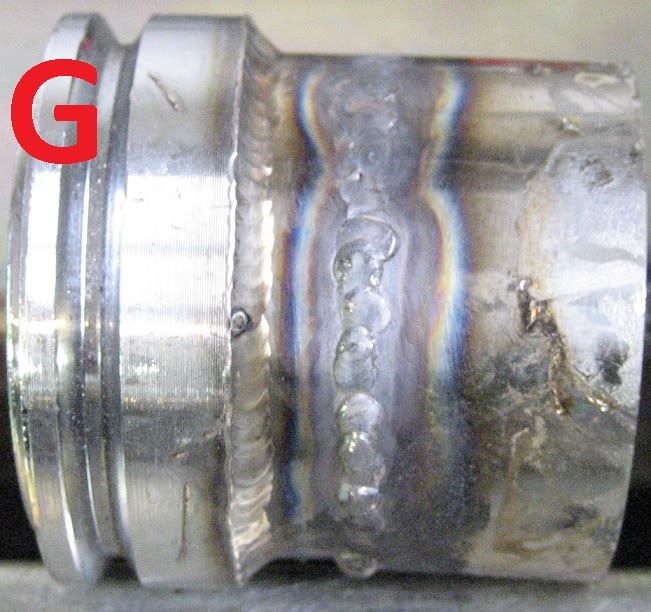

I've been trying to weld some stainless steel exhaust pipe (ebay brand) with 316L rod, but I think something is wrong with my settings, technique, or torch setup because all my welds look like crap

Prep: Stainless Steel Brush on surfaces w/ acetone + paper towel cleaning.

Tungsten: 2% lanthanated (3/32 size), sharpened to a point

Amps: 40 (also tried pulsed @ 40/20)

Gas: 100% Argon

Torch: Air cooled Everlast

Torch Flow: ~7-8 L/min

Back Purge: ~2.2 L/min through the pipe

Tungsten protruding distance from #7 EverLast cup = 4.32 mm