I have been ordering cheap no name stainless filler rod from on line.

surfing the web, I see a great difference in filler rod prices between a name brand and these no name brands. Is it worth the extra money to buy the name brand? If so which brands do you like the best?

Thanks

Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process

Ive been testing some Blue Demon 308L filler and can say I actually think it is nicer then the Lincoln material we typically run, that being said unless your having issues it should not matter. The only time I have had filler brand come into question was with some Alum filler (Alco Tec), didn't run very well for me.mpete53 wrote:I have been ordering cheap no name stainless filler rod from on line.

surfing the web, I see a great difference in filler rod prices between a name brand and these no name brands. Is it worth the extra money to buy the name brand? If so which brands do you like the best?

Thanks

Last edited by Rick_H on Thu Oct 06, 2016 10:28 am, edited 1 time in total.

I weld stainless, stainless and more stainless...Food Industry, sanitary process piping, vessels, whatever is needed, I like to make stuff.

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

I buy all of my consumables online because my LWS are all pretty poor when it comes to Tig supplies.

I've bought a lot of filler rod and never met a 'dud' batch yet, i.e the 5356 I buy all welds just fine and behaves very similarly, no matter where I buy.

Tungstens are another matter - I went cheap and bought some no-name 2% Lanthanated ages ago and they simply didn't weld properly or last at all.

Kym

I've bought a lot of filler rod and never met a 'dud' batch yet, i.e the 5356 I buy all welds just fine and behaves very similarly, no matter where I buy.

Tungstens are another matter - I went cheap and bought some no-name 2% Lanthanated ages ago and they simply didn't weld properly or last at all.

Kym

ex framie

- ex framie

-

Ace

-

Posts:

-

Joined:Sun Aug 09, 2015 1:09 am

-

Location:Brisbane QLD Land of oz

Kym, where did you get the suspect tungstens from?

I got some in from weld river that seem OK, I only go through them because I keep dipping into the weld pool

I got some in from weld river that seem OK, I only go through them because I keep dipping into the weld pool

Pete

God gave man 2 heads and only enough blood to run 1 at a time. Who said God didn't have a sense of humour.....

God gave man 2 heads and only enough blood to run 1 at a time. Who said God didn't have a sense of humour.....

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

Hey there framie.ex framie wrote:Kym, where did you get the suspect tungstens from?

I got some in from weld river that seem OK, I only go through them because I keep dipping into the weld pool

Afraid I don't recall - was an online seller, Australian. Most importantly, they came in plain packaging, no name. I make it a rule never to buy no-name stuff anymore, should have been smart enough to know better in the first place.

Kym

Postby GreinTime » Thu Oct 06, 2016 1:15 am

I hate Alcotec rods with a passion.

sam

what is the issue with that brand??

craig

I hate Alcotec rods with a passion.

sam

what is the issue with that brand??

craig

htp invertig 221

syncrowave 250

miller 140 mig

hypertherm plasma

morse 14 metal devil

syncrowave 250

miller 140 mig

hypertherm plasma

morse 14 metal devil

I been using blue demons different types steel wire. Haven't had any problems, however I'm a newb to Tig. Been doing mostly aluminum and bought 10lbs of 3/32 Harris 4043 since it was only twice the price of any 2lbs packages. Thinking about trying some 5356.

As far as tungestn goes I bought some "ABN" brand lanthanated in 1/16" and 3/32" seems to be good. Not dipping them as much. I usually buy my stuff on Amazon. LWS is a bit pricy.

As far as tungestn goes I bought some "ABN" brand lanthanated in 1/16" and 3/32" seems to be good. Not dipping them as much. I usually buy my stuff on Amazon. LWS is a bit pricy.

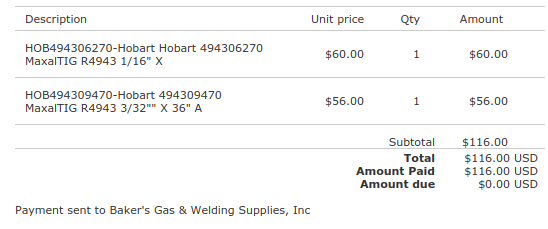

Also, just so you know, Hobart/Maxal ER4943 costs pretty much the same as 4043, but is a lot stronger even without heat treat.Solidcore wrote:I been using blue demons different types steel wire. Haven't had any problems, however I'm a newb to Tig. Been doing mostly aluminum and bought 10lbs of 3/32 Harris 4043 since it was only twice the price of any 2lbs packages. Thinking about trying some 5356.

As far as tungestn goes I bought some "ABN" brand lanthanated in 1/16" and 3/32" seems to be good. Not dipping them as much. I usually buy my stuff on Amazon. LWS is a bit pricy.

$56-60 for a 10lbs box through Baker's Gas & Supplies. You just have to email them to send you a quote, and they drop ship it straight from Hobart/Maxal.

Jim FLinchbaugh

- Jim FLinchbaugh

-

Workhorse

-

Posts:

-

Joined:Thu Sep 01, 2016 11:56 pm

-

Location:Kalispell Montana

I bought the same for my initial supply up for the new welder, I thought they seemed alright. I don't have a lot of recent TIG experience though so I maybe wouldn't know the difference. Glad to hear some one else likes themSolidcore wrote:

As far as tungestn goes I bought some "ABN" brand lanthanated in 1/16" and 3/32" seems to be good. Not dipping them as much. I usually buy my stuff on Amazon. LWS is a bit pricy.

exnailpounder

- exnailpounder

-

Weldmonger

-

Posts:

-

Joined:Thu Dec 25, 2014 9:25 am

-

Location:near Chicago

Last edited by exnailpounder on Fri Oct 07, 2016 7:06 am, edited 1 time in total.

Ifyoucantellmewhatthissaysiwillbuyyouabeer.

GreinTime

- GreinTime

-

Weldmonger

-

Posts:

-

Joined:Fri Nov 01, 2013 11:20 am

-

Location:Pittsburgh, PA

I've never grabbed a rod out of the box that the bead didn't look like dog shit. Aesthetically speaking. I mean the weld itself is nice, but it's a super grainy finish rather than shiny. Switch to a different rod, instant improvement.motox wrote:Postby GreinTime » Thu Oct 06, 2016 1:15 am

I hate Alcotec rods with a passion.

sam

what is the issue with that brand??

craig

Sent from my SM-G900V using Tapatalk

#oneleggedproblems

-=Sam=-

-=Sam=-

- Otto Nobedder

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 06, 2011 11:40 pm

-

Location:Near New Orleans

I'll go one further.GreinTime wrote:I've never grabbed a rod out of the box that the bead didn't look like dog shit. Aesthetically speaking. I mean the weld itself is nice, but it's a super grainy finish rather than shiny. Switch to a different rod, instant improvement.motox wrote:Postby GreinTime » Thu Oct 06, 2016 1:15 am

I hate Alcotec rods with a passion.

sam

what is the issue with that brand??

craig

Sent from my SM-G900V using Tapatalk

I was welding 1/2" 6061 in 4G, using 1/8" Oxford brand 5356, and ran out. Found a box of Alcotec 1/8" 5356, and kept going... briefly. I could NOT stab the rod in the puddle fast enough to keep it from balling and dripping every other dip. After the 3rd time I didn't successfully dodge the meteor and got a third-degree burn, the whole box went in the bin, and I refused to continue until they brought some more Oxford.

Steve S

I use Harris. It's what the LWS stocks. I use everything from there tig wire to there brazing rod. It always seems concistant from box to box. I grabbed a partial box of some Alcotec wire one time! There now used to secure my chain link fence to keep it from sagging.

I have more questions than answers

Josh

Josh

I had a similar experience with the Alcotec, left a bad taste in my mouth. It looked like I had never welded alum before...Otto Nobedder wrote:I'll go one further.GreinTime wrote:I've never grabbed a rod out of the box that the bead didn't look like dog shit. Aesthetically speaking. I mean the weld itself is nice, but it's a super grainy finish rather than shiny. Switch to a different rod, instant improvement.motox wrote:Postby GreinTime » Thu Oct 06, 2016 1:15 am

I hate Alcotec rods with a passion.

sam

what is the issue with that brand??

craig

Sent from my SM-G900V using Tapatalk

I was welding 1/2" 6061 in 4G, using 1/8" Oxford brand 5356, and ran out. Found a box of Alcotec 1/8" 5356, and kept going... briefly. I could NOT stab the rod in the puddle fast enough to keep it from balling and dripping every other dip. After the 3rd time I didn't successfully dodge the meteor and got a third-degree burn, the whole box went in the bin, and I refused to continue until they brought some more Oxford.

Steve S

I know they are popular with alum guys and many like them so I was hoping it was an isolated experience, I was not exactly sure how old the rod was but it was sealed and clean, and I wiped with acetone first as well.

I weld stainless, stainless and more stainless...Food Industry, sanitary process piping, vessels, whatever is needed, I like to make stuff.

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

rprecision

- rprecision

-

New Member

-

Posts:

-

Joined:Thu May 05, 2016 9:47 pm

That makes three of us. I find they work better if you don't stir in the filler with them.Jim FLinchbaugh wrote:I bought the same for my initial supply up for the new welder, I thought they seemed alright. I don't have a lot of recent TIG experience though so I maybe wouldn't know the difference. Glad to hear some one else likes themSolidcore wrote:

As far as tungestn goes I bought some "ABN" brand lanthanated in 1/16" and 3/32" seems to be good. Not dipping them as much. I usually buy my stuff on Amazon. LWS is a bit pricy.

I have used Harris 4043,5356 and blue demon ER70S2. Can't say I can attribute any flaws to the filler........

But I'm as fresh as they come to TIG

- entity-unknown

-

Ace

-

Posts:

-

Joined:Mon Jul 18, 2016 2:07 pm

-

Location:Mesa, AZ

I don't think I'll ever think of Alcotel now... Thanks all!

My results so far have been great with Blue Demon and the Hobart Maxall 4943. I could only get the 4943 in 1/8 but will check the local welding supply for some 3/32 since 1/8 is too thick for 1/8 or 1/16 material and sucks out too much heat but can definitely get the job done and done well if you're careful.

Only one I wasn't too pleased with was Blue Demon 3/32 5356. It seemed hard to control, the puddle did not seem to be visible at all and the finish was hard to get nice. I have very little seat time with that one but could easily make a decent bead with 4X43, move to 5356, have it run like crap, move to 4X43 and still look good. There's something to learn about that 5356 and I wouldn't pass it up just cuz it's difficult, it just may be like 7018 vs. 601X is to stick. It'd be my choice for my high strength project is I wasn't exposing it to over 150F degrees which is a listed limitation of 5356 too.

What I've used so far and works great IF I have a nicely ground Tungsten (3/32 or 1/8 2% Lan for me) with NO flat spots or run offs, IF I get my Amps/pedal in tune AND IF my rods came in a 10Lbs card board box and really just always I clean them off gently:

Blue Demon

3/32 70S2 (Works great! Mixes well with 308L/309L too but metalurgically/X-ray might say otherwise. Decent Amp/Pedal control and I get great finish welds often even when slackin/n00b'in. Very easy to control, handles bein close to the Tungsten at 50-230A without balling up all crazy, easy puddle control, seriously almost fool proof rod)

3/32 4043 (Very happy all around on 1/16, 1/8 and those two layered. Gas lens seemed more important than Argon CFH but Amp/pedal control trumped both for a beautiful finish)

3/32 308L (Very pleased from perfect silver to cotton candy on 1/16 and 1/8 material with "Rule of 33" and/or straight pedal. CFH + Gas Lens + Perfect Amp/Pedal = Beautiful finish )

1/8 309L (Not so easy but possible on first pass on 1/8 corner SS but worked beautifully for 2nd pass due to 1/8 size and n00b'in with more cotton candy colors than silver but still n00b'in. Still 3/32 or 1/16 would have been better. CFH + Gas Lens + Perfect Amp/Pedal = Beautiful finish )

Hobart/Maxall

1/8 4943 (Need 3/32 for 1/8 or 1/16 but still works great, beautiful finish, and less need to feed if you can control it. Gas lens seemed more important than Argon CFH but Amp/pedal control trumped both for a beautiful finish )

My results so far have been great with Blue Demon and the Hobart Maxall 4943. I could only get the 4943 in 1/8 but will check the local welding supply for some 3/32 since 1/8 is too thick for 1/8 or 1/16 material and sucks out too much heat but can definitely get the job done and done well if you're careful.

Only one I wasn't too pleased with was Blue Demon 3/32 5356. It seemed hard to control, the puddle did not seem to be visible at all and the finish was hard to get nice. I have very little seat time with that one but could easily make a decent bead with 4X43, move to 5356, have it run like crap, move to 4X43 and still look good. There's something to learn about that 5356 and I wouldn't pass it up just cuz it's difficult, it just may be like 7018 vs. 601X is to stick. It'd be my choice for my high strength project is I wasn't exposing it to over 150F degrees which is a listed limitation of 5356 too.

What I've used so far and works great IF I have a nicely ground Tungsten (3/32 or 1/8 2% Lan for me) with NO flat spots or run offs, IF I get my Amps/pedal in tune AND IF my rods came in a 10Lbs card board box and really just always I clean them off gently:

Blue Demon

3/32 70S2 (Works great! Mixes well with 308L/309L too but metalurgically/X-ray might say otherwise. Decent Amp/Pedal control and I get great finish welds often even when slackin/n00b'in. Very easy to control, handles bein close to the Tungsten at 50-230A without balling up all crazy, easy puddle control, seriously almost fool proof rod)

3/32 4043 (Very happy all around on 1/16, 1/8 and those two layered. Gas lens seemed more important than Argon CFH but Amp/pedal control trumped both for a beautiful finish)

3/32 308L (Very pleased from perfect silver to cotton candy on 1/16 and 1/8 material with "Rule of 33" and/or straight pedal. CFH + Gas Lens + Perfect Amp/Pedal = Beautiful finish )

1/8 309L (Not so easy but possible on first pass on 1/8 corner SS but worked beautifully for 2nd pass due to 1/8 size and n00b'in with more cotton candy colors than silver but still n00b'in. Still 3/32 or 1/16 would have been better. CFH + Gas Lens + Perfect Amp/Pedal = Beautiful finish )

Hobart/Maxall

1/8 4943 (Need 3/32 for 1/8 or 1/16 but still works great, beautiful finish, and less need to feed if you can control it. Gas lens seemed more important than Argon CFH but Amp/pedal control trumped both for a beautiful finish )

Lincoln Electric AC225

Everlast PowerPro Multi-Process TIG/Stick/Plasma 256Si

Everlast W300 WaterCooler

Optrel e684x1

22+ Year Security Engineer developing cool shit and stoppin hackers

Everlast PowerPro Multi-Process TIG/Stick/Plasma 256Si

Everlast W300 WaterCooler

Optrel e684x1

22+ Year Security Engineer developing cool shit and stoppin hackers

Return to “Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities