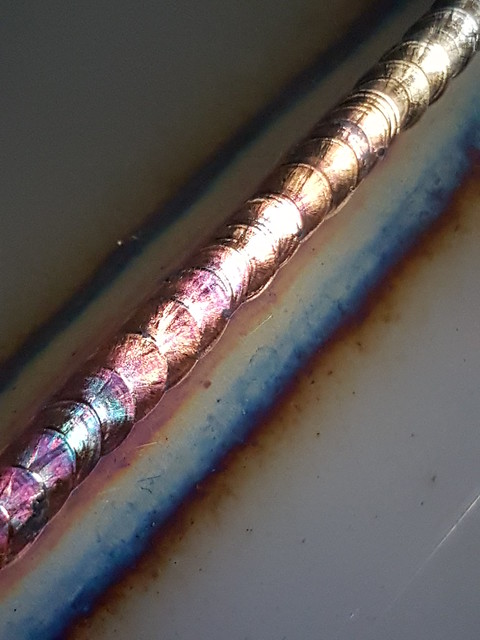

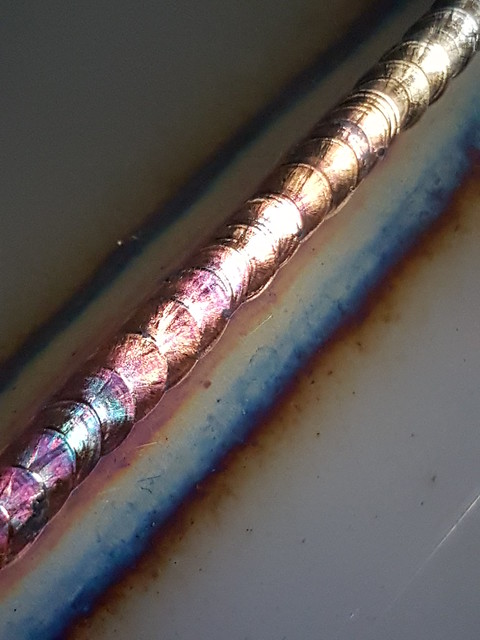

Saturday job putting in this 5" sched40 crossover. Took me 15 hours including pumpout and re-start. Was a tied joker at the end of the day but still made it out for oysters, steak and beer at about 9pm. The first beer was for my good mate Exie!!

As a point of interest, the elbow on the right is of chinese manufacture. Supposed to be sched40 but actual wall thickness was between sched 40 & 80! And the big thing is that it wasn't 90* !!! What's up with that? You can see the 5G butt is alot wider than the 2G butt, that's because I tacked it on the outside 2.4mm gap (3/32") and had about 8.5mm (11/32") gap to fill on the inside to square it up. Beware crap from China!

Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process

- LtBadd

-

Weldmonger

-

Posts:

-

Joined:Sun Apr 12, 2015 4:00 pm

-

Location:Clearwater FL

-

Contact:

I know what you mean about the 90's, we did a lot of 316 pipe work and the elbows were pretty good, got into some duplex and the material seemed really thick for schedule 40, nice looking work there!Coldman wrote:

Saturday job putting in this 5" sched40 crossover. Took me 15 hours including pumpout and re-start. Was a tied joker at the end of the day but still made it out for oysters, steak and beer at about 9pm. The first beer was for my good mate Exie!!

As a point of interest, the elbow on the right is of chinese manufacture. Supposed to be sched40 but actual wall thickness was between sched 40 & 80! And the big thing is that it wasn't 90* !!! What's up with that? You can see the 5G butt is alot wider than the 2G butt, that's because I tacked it on the outside 2.4mm gap (3/32") and had about 8.5mm (11/32") gap to fill on the inside to square it up. Beware crap from China!

Richard

Website

Website

That's a big problem here too. I've had fittings so bad that it's like welding togeather different diameter pipe. Or there not round. That sucks when you have to clock a fitting in a certain position but the one you are up against is out of round in a different direction than the other.

I have more questions than answers

Josh

Josh

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

I've been slack and haven't posted much lately.

Getting lots of little jobs now for my motorcycle racing mates. Below is a battery/electrics box for a race bike. Made with 3mm scrap aluminium, filler is 2mm 5356.

Not weldporn by any means, but finding that 1 pps gives me that 'metronome' I need to make my beads reasonably even.

Moz

Getting lots of little jobs now for my motorcycle racing mates. Below is a battery/electrics box for a race bike. Made with 3mm scrap aluminium, filler is 2mm 5356.

Not weldporn by any means, but finding that 1 pps gives me that 'metronome' I need to make my beads reasonably even.

Moz

- Attachments

-

- battery box.jpg (30.21 KiB) Viewed 3408 times

-

- bead detail.jpg (34.92 KiB) Viewed 3412 times

- LtBadd

-

Weldmonger

-

Posts:

-

Joined:Sun Apr 12, 2015 4:00 pm

-

Location:Clearwater FL

-

Contact:

Hey Kym, nice small fab work there, good to see ya againMosquitoMoto wrote:I've been slack and haven't posted much lately.

Getting lots of little jobs now for my motorcycle racing mates. Below is a battery/electrics box for a race bike. Made with 3mm scrap aluminium, filler is 2mm 5356.

Not weldporn by any means, but finding that 1 pps gives me that 'metronome' I need to make my beads reasonably even.

Moz

Richard

Website

Website

- MosquitoMoto

-

Weldmonger

-

Posts:

-

Joined:Sat Aug 01, 2015 8:38 am

-

Location:The Land Down Under

LtBadd wrote:Hey Kym, nice small fab work there, good to see ya againMosquitoMoto wrote:I've been slack and haven't posted much lately.

Getting lots of little jobs now for my motorcycle racing mates. Below is a battery/electrics box for a race bike. Made with 3mm scrap aluminium, filler is 2mm 5356.

Not weldporn by any means, but finding that 1 pps gives me that 'metronome' I need to make my beads reasonably even.

Moz

Thanks so much Richard.

One of the great pleasures of welding is to be useful enough to help your friends out.

Moz

- LtBadd

-

Weldmonger

-

Posts:

-

Joined:Sun Apr 12, 2015 4:00 pm

-

Location:Clearwater FL

-

Contact:

- Otto Nobedder

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 06, 2011 11:40 pm

-

Location:Near New Orleans

Amen, and well done!LtBadd wrote:Congrats Josh, I'm sure it's well deserved!Poland308 wrote:Woo hoo! Passed the weld test for my R stamp! First project is on Friday. Chasing cracks on the tube sheet on an old steam boiler. I'll try to post some pics.

I've passed my IX qual, and qualified some procedures. We're still waiting on the NB audit to give us our "R" stamp. Coming soon, to a theater near you.

Also, I now have to qualify on aluminum for a particular repair (and write a procedure, and qualify it)... Damn it!

Steve

Picked this little job up yesterday. Delivered today. Everything went just as planned which was nice since it usually doesn't go that way for me. Especially on aluminum. It was very dirty and oily but it cleaned up good. It's an oil pan for chevy aveo. I didn't think to grind off the weld where the plug goes back in but the mechanic said it was fine. Had a little porosity at the starts but after I ground it out the next weld was fine.

- Attachments

-

- Stop drilled

- IMG_1010.JPG (25.22 KiB) Viewed 3327 times

-

- Ground out with the new dremel I haven't gotten to use yet!!

- IMG_1011.JPG (37.38 KiB) Viewed 3327 times

-

- Finished up

- IMG_1012.JPG (30.16 KiB) Viewed 3327 times

What brand bender is that?

Pete

Esab SVI 300, Mig 4HD wire feeder, 30A spool gun, Miller Passport, Dynasty 300 DX, Coolmate 4, Spectrum 2050, C&K Cold Wire feeder WF-3, Black Gold Tungsten Sharperner, Prime Weld 225

Esab SVI 300, Mig 4HD wire feeder, 30A spool gun, Miller Passport, Dynasty 300 DX, Coolmate 4, Spectrum 2050, C&K Cold Wire feeder WF-3, Black Gold Tungsten Sharperner, Prime Weld 225

- 5th Street Fab

-

Guide

-

Posts:

-

Joined:Sun Jan 15, 2017 1:08 am

Interesting bender! Ive got some questions hahaGreinTime wrote:First bends with the new bender!

Sent from my VS995 using Tapatalk

What's the brand?

Price?

180 dies?

Where to find?

Those bends look nice I don't see any kinks.

Sent from my SM-G920V using Tapatalk

GreinTime

- GreinTime

-

Weldmonger

-

Posts:

-

Joined:Fri Nov 01, 2013 11:20 am

-

Location:Pittsburgh, PA

I sent you a DM on Instagram with my phone number so you can ask any specific questions you have about the bender, or anything else for that matter.5th Street Fab wrote:Interesting bender! Ive got some questions hahaGreinTime wrote:First bends with the new bender!

Sent from my VS995 using Tapatalk

What's the brand?

Price?

180 dies?

Where to find?

Those bends look nice I don't see any kinks.

Sent from my SM-G920V using Tapatalk

In order:

RogueFab M600 Tradesmen Set. Typically comes with 1x3.5, 1.25x4.5, 1.5x4.5, 1.75x6, and 2x6 dies. I swapped the 2x6 for the 1.625x6 as I don't feel that we (business partner and I) need at this point. If someone wants anything that big bent, the price of the die will be added to the price of the job.

Price: With roller pressure dies, which are 360 aluminum rollers with the matching tube size that the tube rests on as it pulls through the bender instead of a block with the radius milled in it. Cuts down on friction, allows you to bend stainless or aluminum without scratching it, things like that. Price was $1875, with shipping to my area it was $1987. I believe they are in Oregon actually, so you'd be able to pick it up locally and save some cash. **Also, this was the weld together kit, I'll get it powder coated locally.

Degree: If you could split the die in half on the centerline, you could bend 360. The dies are full diameter of die radius, with the tube profile cut in. Anything over 180 though you'd get stuck.

Where to find: https://www.roguefab.com/product-catego ... g-benders/

I bought the cylinder from Harbor Freight locally to save more money on shipping.

Bend quality is good as you can see. That was 1.5x.120, and bent great. I don't have the degree sticker on there, as I have to get it powder coated yet, but it seems that 0-~90° was one full stroke of the ram. I didn't repin to try and bend any farther, but that was 49 seconds or so with stopping once or twice to check things. The biggest selling point in my mind is that you can bend up to 1.5 solid bar with the HD kit, up to 0.250 wall 1.75, and up to 0.188 wall 2.0.

It's a little awkward to change dies, but it was the first time trying it, it should get easier from there.

I will keep everyone posted, I have a tube front on an S13 Nissan 240sx hatchback to do first, followed by an FD Mazda RX7 (1993 for you old folks who don't know chassis codes) and an 80's AE86 Corolla, back when they were RWD and cool [FACE WITH TEARS OF JOY] So I should be putting it through it's paces pretty quickly.

Sent from my VS995 using Tapatalk

#oneleggedproblems

-=Sam=-

-=Sam=-

Just mucking around with some outside corner joints on 16ga stainless.. I experimented using pulse, as well as filler and no filler joints. All joints were welded with a 3/32" 2% Lanthanated Tungsten, Furick Fupa 12 with aluminium angle for backing. I had 100 amps set on the machine but didn't go anywhere near that..I think I had about 12LPM argon flow.

No pulse, 1/16" 308L filler:

1pps, 100 amps, 30% peak current and 20% background current, 1/16" 308L filler:

Same settings as above sans filler:

I only ran 6 coupons but I can definitely see the benefit that using a smaller diameter tungsten and filler would have on thin material.

Flo

No pulse, 1/16" 308L filler:

1pps, 100 amps, 30% peak current and 20% background current, 1/16" 308L filler:

Same settings as above sans filler:

I only ran 6 coupons but I can definitely see the benefit that using a smaller diameter tungsten and filler would have on thin material.

Flo

- LtBadd

-

Weldmonger

-

Posts:

-

Joined:Sun Apr 12, 2015 4:00 pm

-

Location:Clearwater FL

-

Contact:

way to lay it down Flo, very niceOzFlo wrote:Just mucking around with some outside corner joints on 16ga stainless.. I experimented using pulse, as well as filler and no filler joints. All joints were welded with a 3/32" 2% Lanthanated Tungsten, Furick Fupa 12 with aluminium angle for backing. I had 100 amps set on the machine but didn't go anywhere near that..I think I had about 12LPM argon flow.

I only ran 6 coupons but I can definitely see the benefit that using a smaller diameter tungsten and filler would have on thin material.

Flo

Richard

Website

Website

Thanks Richard. This is the same material that I'm going to build my water cooler reservoir from so I want to get some good practice before attempting to weld that up. I didn't use any chill bars on the face side of the material when I welded those coupons but definitely will be when I attempt the real thing.LtBadd wrote: way to lay it down Flo, very nice

Flo

- LtBadd

-

Weldmonger

-

Posts:

-

Joined:Sun Apr 12, 2015 4:00 pm

-

Location:Clearwater FL

-

Contact:

Make sure to document your build, we'll all benefit from itOzFlo wrote: Thanks Richard. This is the same material that I'm going to build my water cooler reservoir from so I want to get some good practice before attempting to weld that up. I didn't use any chill bars on the face side of the material when I welded those coupons but definitely will be when I attempt the real thing.

Flo

Richard

Website

Website

Return to “Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities