Page 1 of 1

Welding acute angles on thinwall tubing joints

Posted: Thu May 01, 2014 5:35 pm

by Trevor Schwealdson

Hello,

I've recently been required to do some welding of 1" round .063 wall steel tubes where I am butting the end of one tube against the broadside of another tube. I've cut open some of these joints to see penetration, and one place I seem to have difficulty is the inside corner of the joint, in the acuter angle. When I get the electrode down in there, the arc wants to jump off to either side, rather than down into the root. Do I just need to get a tighter arc and a pointier electrode, or is there some aspect of technique that I'm missing? Is it necessary to get the puddle all the way into the very root, or is a bridged weld similarly strong in that particular spot?

Pardon my ignorance, thanks for your suggestions.

Trevor

Re: Welding acute angles on thinwall tubing joints

Posted: Thu May 01, 2014 6:12 pm

by zank

Hi Trevor,

Acute angles can be nasty. I try to get down to the root and avoid just bridging. My technique is to move ahead and wash the metal into the root, and then back up a half step and dip. Then move ahead again and wash into the root. Back half step and dip. Lather, rinse, repeat. Well, sometimes it's more of a push of the filler rather than just a dab. There's a lot to fill there compared to the sides of the joint. If you want your bead width consistent all the way around, this will be an area where more filler is needed.

This joint is 60 degrees.

Dave R

Dave R by

Zanconato Custom Cycles, on Flickr

This one is a little easier at 73 degrees.

Eric N

Eric N by

Zanconato Custom Cycles, on Flickr

Re: Welding acute angles on thinwall tubing joints

Posted: Fri May 02, 2014 9:58 pm

by Trevor Schwealdson

Wow, beautiful job. I'll work on applying your technique next time around.

I'd like to eventually get good enough to build bikes, because I'm a leggy 6'8" bike nerd who can never find a frame big enough. My buddy's got a frame fixture too, but he fillet brazes.

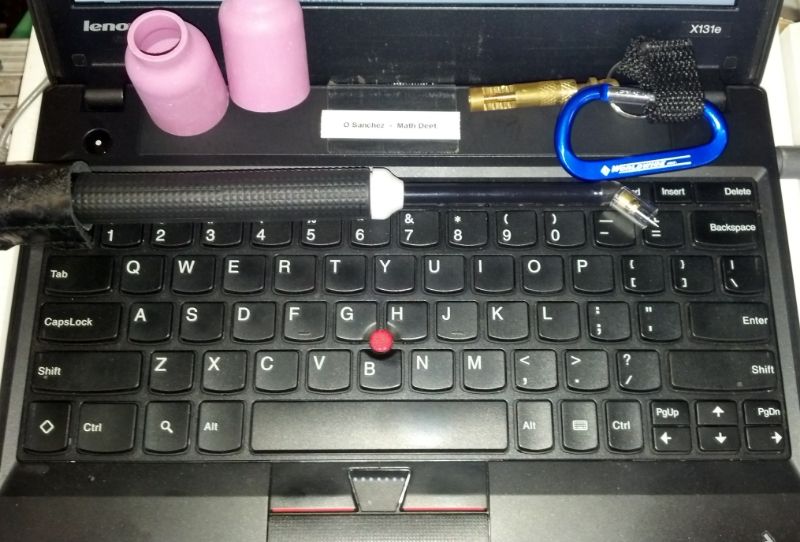

My most recent project that I finished was a mobile bike repair workstation, I'll see if I can figure out how to upload a photo here...

[img]IMG_0306.JPG[/img]

Re: Welding acute angles on thinwall tubing joints

Posted: Sat May 03, 2014 12:24 am

by Oscar

Since it's only 0.063" wall, you should be at most using a 1/16" electrode. Lots of missing info here. If for one you are trying to use a 3/32" electrode, unless you have a taper that is 8-10x the electrode diameter, you won't have a "pointed" enough electrode and that causes arc wander because the sides of the electrode are closer to the tubes than the point is to the root. A 1/16" tungsten electrode with a taper at about 3-4x the diameter will help you out tremendously. Again, we don't know how much taper you are currently putting on your tungsten, so we are only left to guess that they probably aren't sharp enough, are too big a diameter, or maybe even both. I personally have used a 0.040" tungsten---they can handle about 80A or so, so they too can be used if they must be.

Re: Welding acute angles on thinwall tubing joints

Posted: Sat May 03, 2014 2:06 am

by Trevor Schwealdson

Yep, I've been using 1/16" electrodes, but sounds like I could do to sharpen them a little pointier, thanks.

Re: Welding acute angles on thinwall tubing joints

Posted: Mon May 05, 2014 9:20 pm

by Oscar

Re: Welding acute angles on thinwall tubing joints

Posted: Mon May 05, 2014 9:37 pm

by Superiorwelding

I have been drooling over one of these, will have to put it on the list. That would get into the tight joints for sure.

-Jonathan