Page 1 of 1

AC Balance Explanation

Posted: Tue Jun 16, 2015 9:45 am

by DieselTuner

Gday guys. Beginner welder here only very limited experience with TIG in a mechanical shop for various repairs and these kinds of things.

Currently running with a Renegade 200A ac/dc machine from a local parts supplies shop. Im sure its the same as alot of the chinese welders available out there currently. Cost around $1200.

https://www.tradetools.com/product-rang ... -foot-ctrl

Now, im pretty handy with a tig on alloy. I have used Kemppi, Lincoln and Fronius welders over the years and they all have the basic ac balance setting which I always found pretty easy to understand and use.

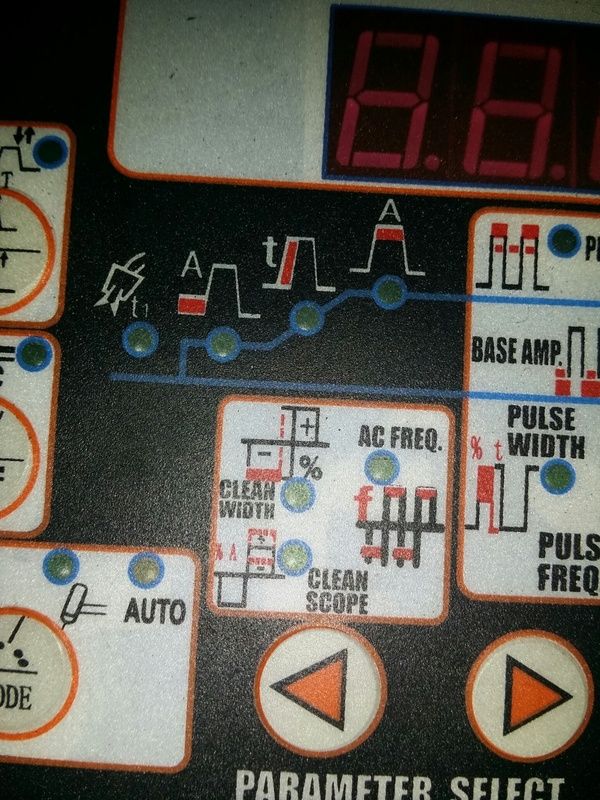

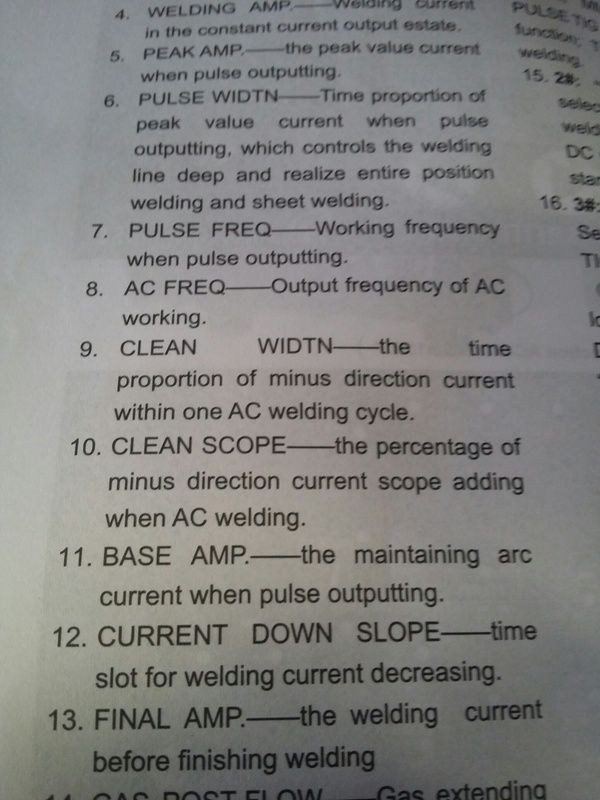

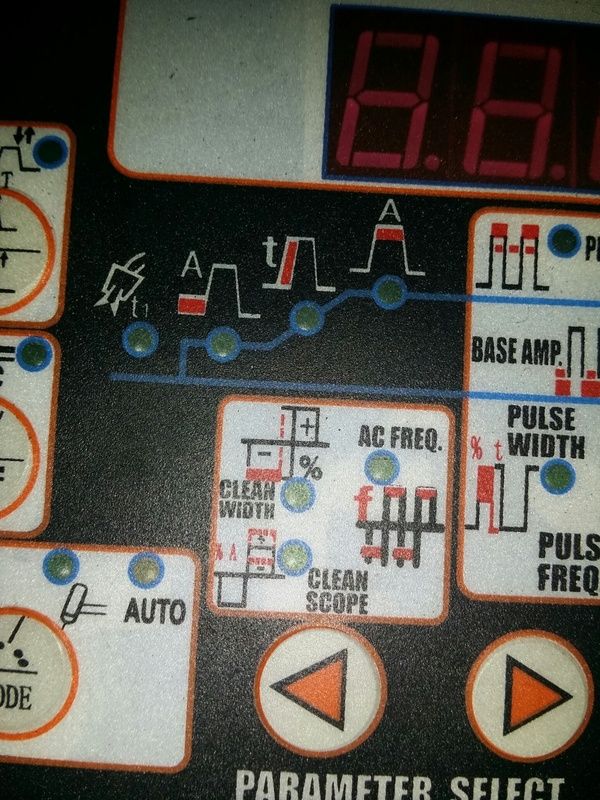

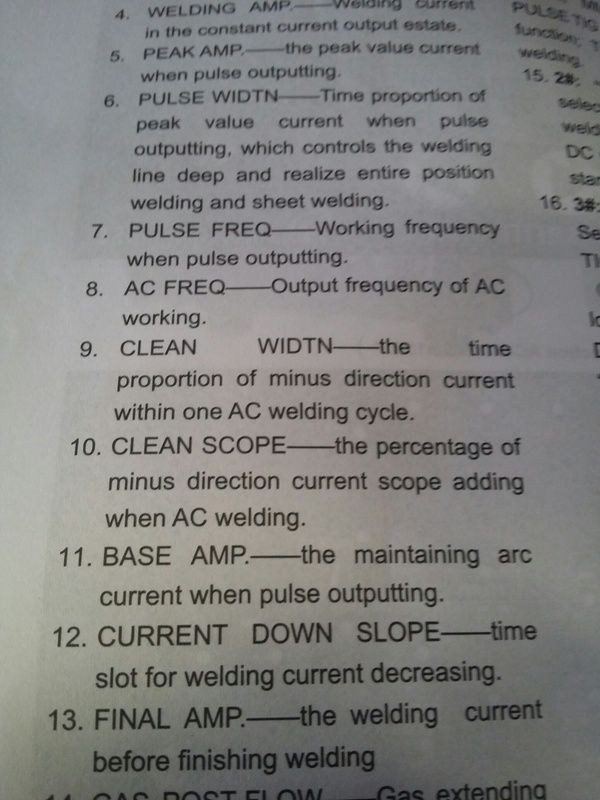

This new machine has Cleaning Width and Cleaning Force (or something like that from memory).

Now I have played around with the settings up and down and I can get it to weld nice on new plate alloy but any part that has been in service is just disgustingly dirty regardless of how much I clean it.

My main question is how do these two setting relate to each other.

Im sure one is the amount of time spent on the negative cycle of ac, of which I set to -40 hoping this is 60% on the negative side for cleaning?

And the other is maybe the amount of current applied on that cycle?

I can post a pic tomorrow of the setting pictures on the welder

Re: AC Balance Explanation

Posted: Tue Jun 16, 2015 1:21 pm

by Oscar

Whatever you do, don't weld like that person in that video! Must be holding the torch at a 45° angle(!)

What does the owners manual have to say about those settings?

Re: AC Balance Explanation

Posted: Tue Jun 16, 2015 2:35 pm

by noddybrian

Hi DieselTuner & welcome to the forum.

I've not yet welded with the digital version of the Chinese welders such as yours - but the answer to your question should be much the same as for the old style with knobs - the closest translation they managed from Chinese means that the control marked cleaning width is AC balance - on a non digital the base setting will be around -2 > -3 ( they are marked minus 5 thru 0 to plus five but have no real known value except by experience ) which is the knob facing about 10 oclock position - on yours I think you need to be set at -25 > -30 don't expect the displayed numbers to have any useful meaning in exact % terms- at least your on the right side of 50 / 50 as your lacking cleaning action & not smoking tungstens - just decrease the negative value a bit at a time until your happy your getting an etched zone ( also check adequate gas flow & cup size ) as to the other control I believe it is unrelated & it's only function is arc force when using the machine as a stick welder - I would set it as low as possible as on the knob style machines if this is left turned up from stick use when doing tig it effects the start amps or slope up when at low current settings such as on thin stainless - by rights it should'nt but is a quirk many WSME style machines have - interested to hear your thoughts on this machine once you've had a bit more seat time - over here the market was flooded with WSME's a few years back - seemed like a cheap deal as they were selling around £400 but they were pretty bad & you don't see them now - most sellers have moved on to better made stuff - I've not come across anyone with this digital version yet - seems like they upped the price some - maybe they're a better machine - hope it works out for you.

Re: AC Balance Explanation

Posted: Tue Jun 16, 2015 6:40 pm

by Bill Beauregard

I'm not familiar with your machine. Is it square wave? Most of the old sine wave machines were 50/50 balance. It worked OK because the EP half of the cycle is not east to establish an arc, much of the energy is in the past by the time electrons flow toward the tungsten. Cleaning is what it is, you can't appreciably change it.

Square wave machines don't coast down to zero current as direction changes. Current goes from full in one direction to full in the other. Plasma, or ionized shielding gas, is still present, work negative arc establishes almost instantly. a setting of 80% Electrode negative gives similar cleaning action to sine wave 50/50.

The only other control to cleaning action I can imagine is amplitude. $8000 machines are equipped with amplitude adjust ability. You can control amperage of both EN and EP while controlling duration.

In any case, heat goes with the flow of electrons. More EN gives more heat in the joint= deeper penetration. More EP gives more cathodic cleaning, and transfers more heat to the tungsten.

Re: AC Balance Explanation

Posted: Wed Jun 17, 2015 6:09 am

by DieselTuner

Thank you very much for the reply guys.

I spend the majority of my work hours tuning engines, and little on fabrication so understanding some of the terminology is like trying to read another language for me at times.

I did read the user manual when I brought the machine but just could not understand what they were talking about, I will post up tomorrow a pic of the snippet they provide maybe some of you guys can decipher it for me!

It does have A% as you can see in the picture and I vaguely remember something about amplitude being mentioned in the user manual.

Even on maximum negative action I cant seem to get a really wide clean area and struggle with contamination getting into the weld on alloy. Now Im starting to put this down possible to the cup supplied with the machine.

I have a gas lense on order from CK which I am hoping might solve the issue for me.

Re: AC Balance Explanation

Posted: Wed Jun 17, 2015 2:37 pm

by noddybrian

Wow - from what I see on the somewhat restricted picture of the controls it's more advanced than I first assumed based on the older builds of similar Chinese imports I've used - I can see why they hiked the price - first thing to clear up is if you go to maximum negative electrode you will get virtually NO cleaning action - just penetration - I would say ignoring the other control dial it to around -20 & see how much heat is in the tungsten against etching - the other control as labelled would seem to be independent amplitude on the positive side - this is really advanced stuff for an import - if you read Zanks post about this you will see he has experimented on a Miller & is using settings that appear strange to those without amplitude - maybe worth a read - I think if it were mine I'd try dialing in say -10 on the cleaning width ( AC balance ) give it a quick try & you should get way more etching than you need & put a lot of heat in the tungsten - now start decreasing the % positive on the second control till you get a compromise of cleaning / heat - all in all I'm very interested to see how this machine turns out once you have it figured.

Re: AC Balance Explanation

Posted: Wed Jun 17, 2015 2:53 pm

by AndersK

I wondered how fast the chineese would pick up this feature once the big names rolled it out.

Quicker than I expected.

Re: AC Balance Explanation

Posted: Thu Jun 18, 2015 8:18 am

by DieselTuner

I may be wrong with my assumptions of it being a 'chinese' machine. But I picked this thing up for only $899AUD trade price including a regulator, tig/stick and foot pedal and a whole heap of tungstens/cups etc..

No way it could be manufactured anywhere else for the price was my opinion.

It is very similar to the Kemppi I used, but actually has more features than it did.

I had more of a play around tonight and I had a pretty decent run with a setting of -20 on the width and -15 on the scope.

Anything above -10ish on width and the tungsten gets way to hot and starts to just melt on alloy with 150+ amps.

Pic of weld below. Remember im just a mechanic, not a welder so no judgement on it please. Its probably the best looking weld ive managed with this machine.

Still cant really see what difference the scope is giving me though.

Explanation from the user manual if it means anything to anybody.

Re: AC Balance Explanation

Posted: Thu Jun 18, 2015 8:21 am

by DieselTuner

Noddybrian, after reading your post a few times I finally get what you are trying to say!

Ill give that a shot tomorrow. Setting the 'balance/width' to -10 and using the other control up and down to see what effect it will have.

Re: AC Balance Explanation

Posted: Thu Jun 18, 2015 9:41 am

by TRACKRANGER

Oscar wrote:Whatever you do, don't weld like that person in that video! Must be holding the torch at a 45° angle(!)

Hmmm... After you mentioned that Oscar, I actually watched the video.

Well, I tried to watch, I grimaced and had to look away a few times, and each time I looked back it was only in the hope that the guy was finished doing whatever it was he was doing. Whew, was that ever a different approach to TIG welding. I think it was really just TIG melting, or TIG heating or something like that. (C'mon now, you couldn't call it "welding").

However, DieselTuner, you're definitely getting pretty reasonable results, obviously you didn't learn TIG technique from that video. <grin> Seems that the machine has some reasonable capabilities.

And welcome to the Forum!

Trev

Re: AC Balance Explanation

Posted: Thu Jun 18, 2015 2:00 pm

by Oscar

man that manual is horribly written!

For the 'cleaning witdn', I suspect that is AC balance with a 0-setting being a 50/50% time-balanced wave for EN/EP. Setting to "-20" means IMO "20 percentage points favoring EN", meaning 70% EN/ 30% EP. That would explain why anything less than "-10", or less than 60%EN, would destroy the tungsten---too much EP for a given tungsten diameter. "-20" seems like a good setting to have, as 70%EN/30% EP is what most aluminum welding dictates anyways.

For the "clean scope", it does seem to be the amplitude control (in terms of percentage of the main welding current) for the EP portion with regards to current (hence the "scope"), as opposed to the time-domain that AC balance controls. I have a feeling that the "adding" portion of the manual definition was a mistranslation with the original word resembling "positive", in which case it would be "the percentage of the EN welding current on the positive half of the AC cycle". I could be wrong though.

Tell us, what are the min/max values for "clean scope"?

Re: AC Balance Explanation

Posted: Fri Jun 19, 2015 3:29 am

by noddybrian

@DieselTuner.

Glad your getting the hang of it - sorry if I ramble & am hard to understand - I'm just not great putting thoughts on paper / screen - in my mind I know what I meant ! I got a spate of people over a couple of years buying import Tig machines & asking me basically why their first welds did'nt look like Jodies ! I played around with a fair few imports - all of them weld OK - some better than others - mostly the books were useless so one needed to understand what the controls were doing without worrying about how they got labelled - like AC balance causes confusion but if you try the control full travel each way it becomes obvious which is positive - some brands are labelled kinda backwards just to confuse things - I think your machine has a very standard simple representation on its display that is quite intuitive - once you have some hours with it I think you will be pleased with your purchase - just don't push the duty cycle as it's not intended to be used as an industrial machine - if this is the start of a trend I reckon the imports will be a very attractive option for hobbyists with amplitude as standard - only complaint is they should give a base line chart with the machine like some new Migs come with so you have an idea where to start - mostly you'll be able to fine tune from there with a little experience - your first beads are looking good - remember you only do epic looking Tig welds if you do it every day - let us know how you get on & what settings you find work for you - not much common info out there yet using separate amplitude as only high end machines have had it till recently.

Re: AC Balance Explanation

Posted: Sat Mar 09, 2019 6:51 am

by rxc3ntr1c

I know this thread is ancient, but I also have this machine and have recently started trying to weld alloy with it after spending a few years do chrome moly. This thread has been invaluable because as pictured the manual leaves a lot to be desired, I've spent a few hours going through YouTube vids that explain the different concepts discussed above and this is what I have come up with.

Clean width: Starting at a base of 50/50 the machine settings will go to -40 and 40 so going to -40 is in fact -90/10. I've been sitting around -30 to -20 with good results.

Clean scope I don't think this is amplitude like on other machines where you can set both dcen and dcep. It appears that you can add/remove only to the dcep side (obviously as it pertains to cleaning but only if the graphic can be believed) and it's a percentage of amps up to 20%, so -20 to 20. I fiddled with the settings as as OP stated I couldn't actually see a noticeable difference so I leave it on 0. Other vids I have watched it really affected the "frost" zone as they called it.

Hope this helps some other poor soul like me confused about the language used on these Chinese machines and desperately searching for answers/starting point

-Tone

Re: AC Balance Explanation

Posted: Thu Nov 14, 2019 3:33 pm

by soton

I found this thread with a google search and I have joined the forum just to say a big thank you for the contributors of this thread.

I have just purchased a cheap Chinese DC/AC machine. The instruction booklet does not give any explanations of the effect of the settings. Now I understand why when I set the 'clean area width' to +40 my tungsten melted.

Again a big thank you and I think that now I have discovered this forum I will be hanging around quite a bit.