Hi all,

I'm new at this. I've been sticking the tungster more than necessary. I will try darkening the shade. I've had it around 10 or so. I'm thinking darker may help me see the tip better???

I guess concurrently is this a safety issue? I've had this helmet for 10 years doing Flux core until 2 weeks ago when I stuck my tip in the TIG arts. In using this helmet I've never had an issue with my eyes. I was concerned at first since when striking the arc I could see a bit of flash before it darkened...maybe a few milliseconds.

should I set it for 11? I've heard I would get a scratchy sensation in the eyes especially when going to sleep? Wives tale?

Many thanks!

Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process

- LtBadd

-

Weldmonger

-

Posts:

-

Joined:Sun Apr 12, 2015 4:00 pm

-

Location:Clearwater FL

-

Contact:

Hey nelson, you should never see a flash with an AD hood, and the auto darkening technology has made some advances in the last ten years, I would strongly recommend looking at a new hood.nelson wrote:Hi all,

I'm new at this. I've been sticking the tungster more than necessary. I will try darkening the shade. I've had it around 10 or so. I'm thinking darker may help me see the tip better???

I guess concurrently is this a safety issue? I've had this helmet for 10 years doing Flux core until 2 weeks ago when I stuck my tip in the TIG arts. In using this helmet I've never had an issue with my eyes. I was concerned at first since when striking the arc I could see a bit of flash before it darkened...maybe a few milliseconds.

should I set it for 11? I've heard I would get a scratchy sensation in the eyes especially when going to sleep? Wives tale?

Many thanks!

With TIG welding you should set the shade so you can distinguish (see) the tip of the tungsten.

Richard

Website

Website

Thanks!

so with a new one I'll not see a brief brightening? It hasn't been an issue and I think I paid about 150 for this.

so with a new one I'll not see a brief brightening? It hasn't been an issue and I think I paid about 150 for this.

Stone knives and bearskins.....and a NEW EVERLAST 164SI !!!

That's my newly shared work welder.

At home I got a Power Tig 185 DV. Nice, but no plasma cutting... Nice tight arc after a second.

That's my newly shared work welder.

At home I got a Power Tig 185 DV. Nice, but no plasma cutting... Nice tight arc after a second.

- LtBadd

-

Weldmonger

-

Posts:

-

Joined:Sun Apr 12, 2015 4:00 pm

-

Location:Clearwater FL

-

Contact:

I recently replaced my 10yo Miller Digital Elite with Millers Digital Infinity, even with the elite I never experienced an arc flash due to the lens not changing quick enough.nelson wrote:Thanks!

so with a new one I'll not see a brief brightening? It hasn't been an issue and I think I paid about 150 for this.

With a new hood you can expect better ergonomics (ie, the headgear) and a view of the arc that has much better color, or I should say a truer color of the arc.

In the product review forum you can find several reviews of current welding hoods.

Richard

Website

Website

HELacey

- HELacey

-

New Member

-

Posts:

-

Joined:Mon Jun 27, 2016 10:40 pm

-

Location:North Carolina, by God!

If you have the option to turn up your sensitivity on the hood, I'd recommend you try that first, and unless I'm running upwards of 200 amps, I don't go darker than a shade 10.

Cold beer and cash money!

First of all, you need to have clear lenses that are pretty much brand new when doing tig, The increased precision of tig welding will be drastically diminished if you're using spatter/dust/scratch covered clear lenses, defeating the purpose. Also, you need to get close to the welding arc. Depending on your eyesight, you need to be no further than 12" from the arc. As was said, you need to have it dark enough that you can see the actual tip of the glowing tungsten distinguished from the light of the electric arc itself. If you see one big bright light "blob" and can't see the tip of the tungsten, then your unnecessarily handicapping yourself from the very beginning.

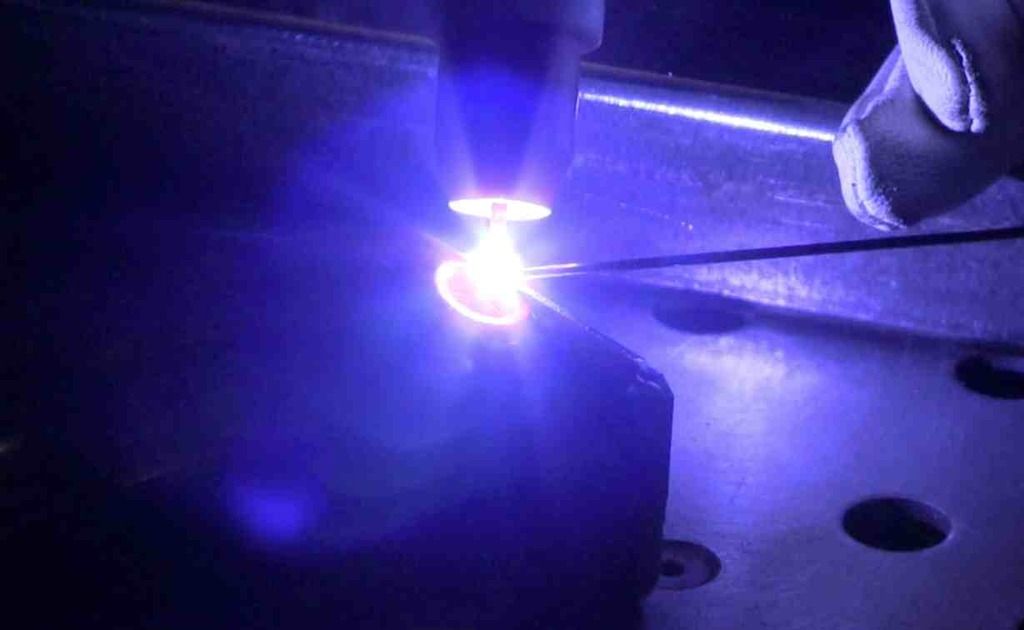

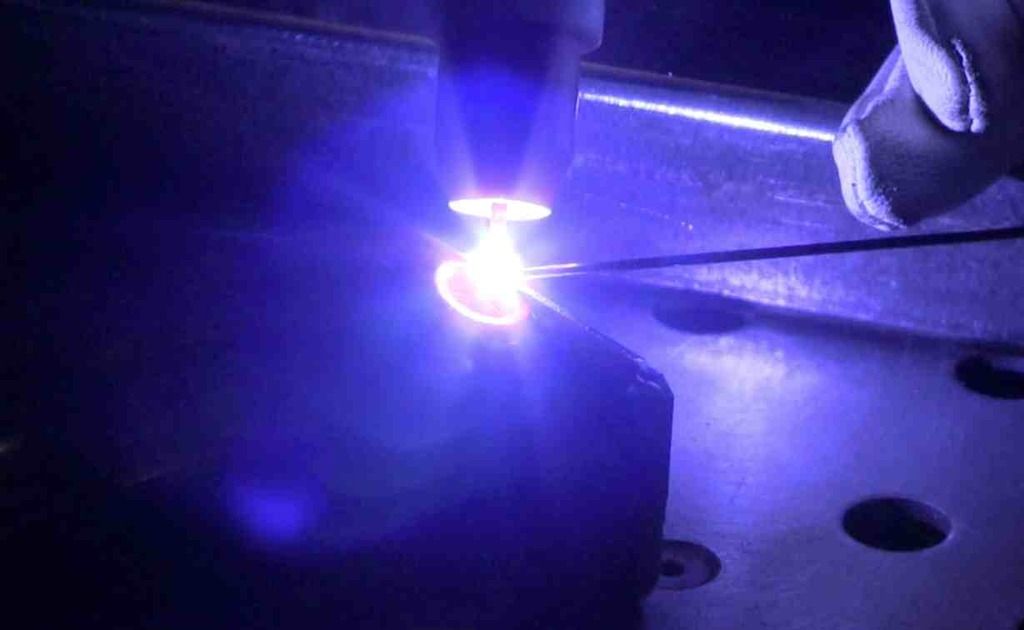

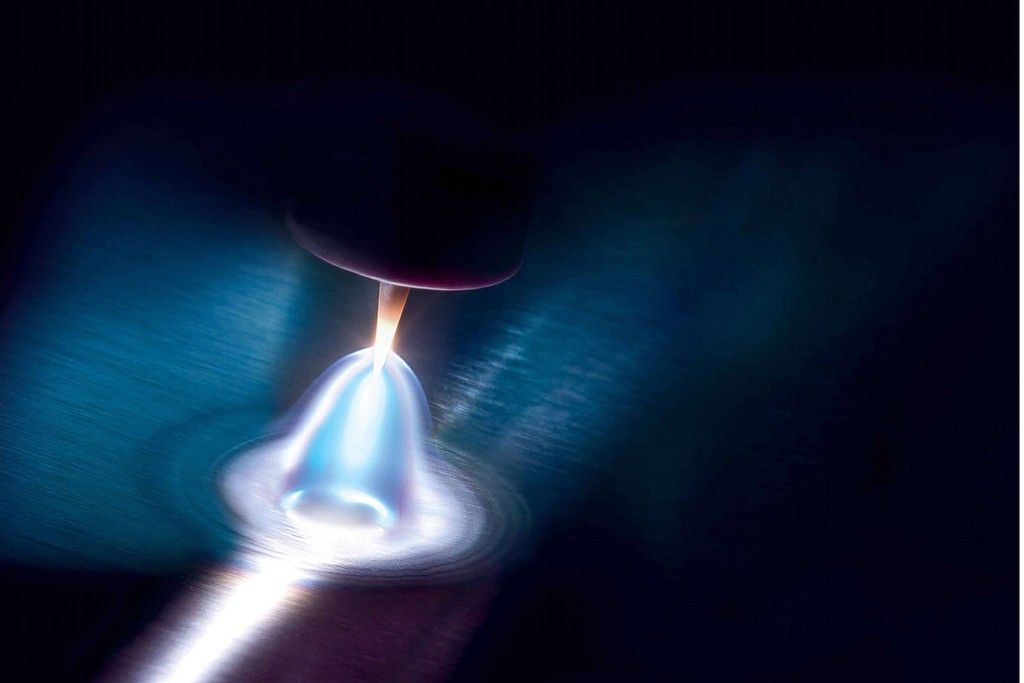

This is NO GOOD. Distance from arc is good, but tip of tungsten is indistinguishable from electric arc light. You see that round, blue aura appearing in the photo? That's what you get with clear lenses in unsuitable state for TIG welding.

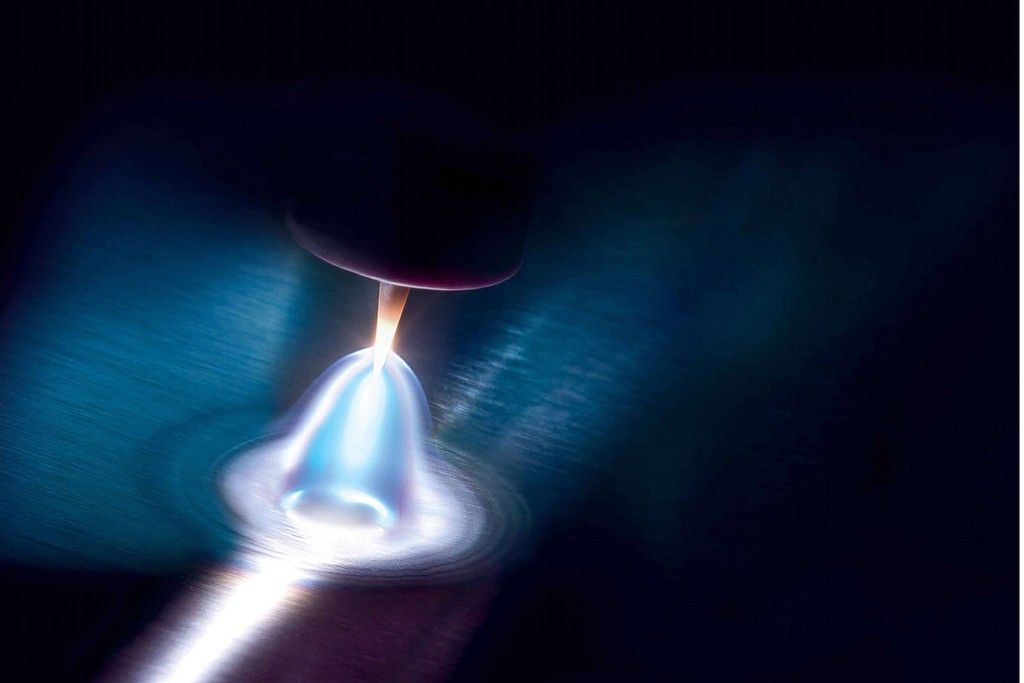

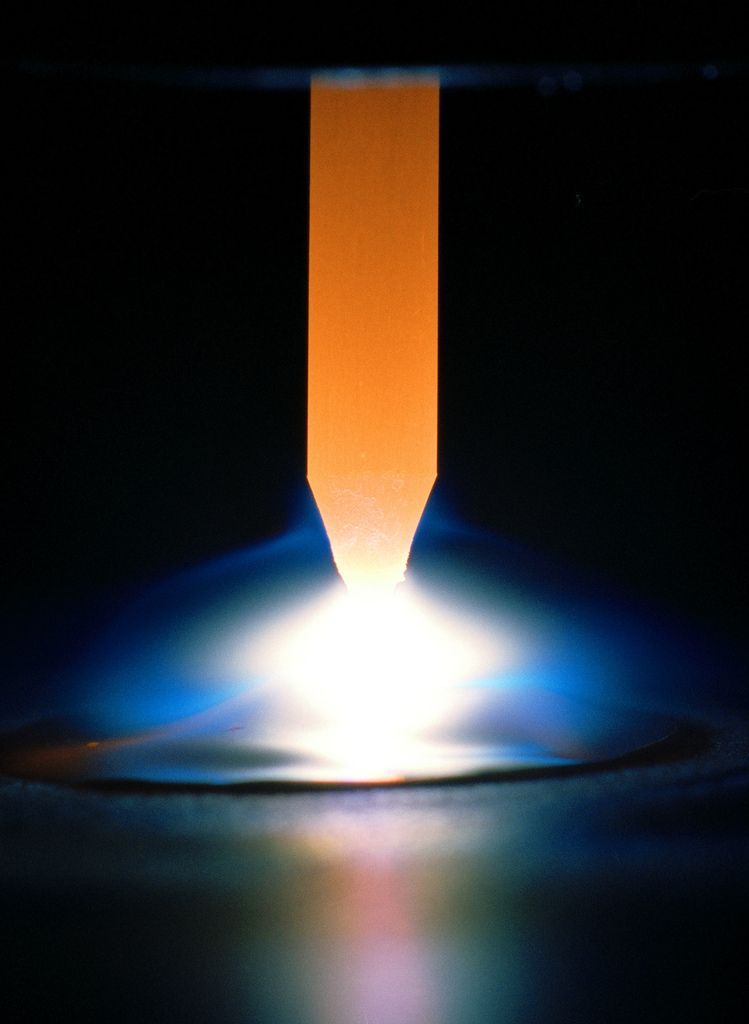

This is much better, BUT there is way too much arc length (probably was just for demonstration purposes)

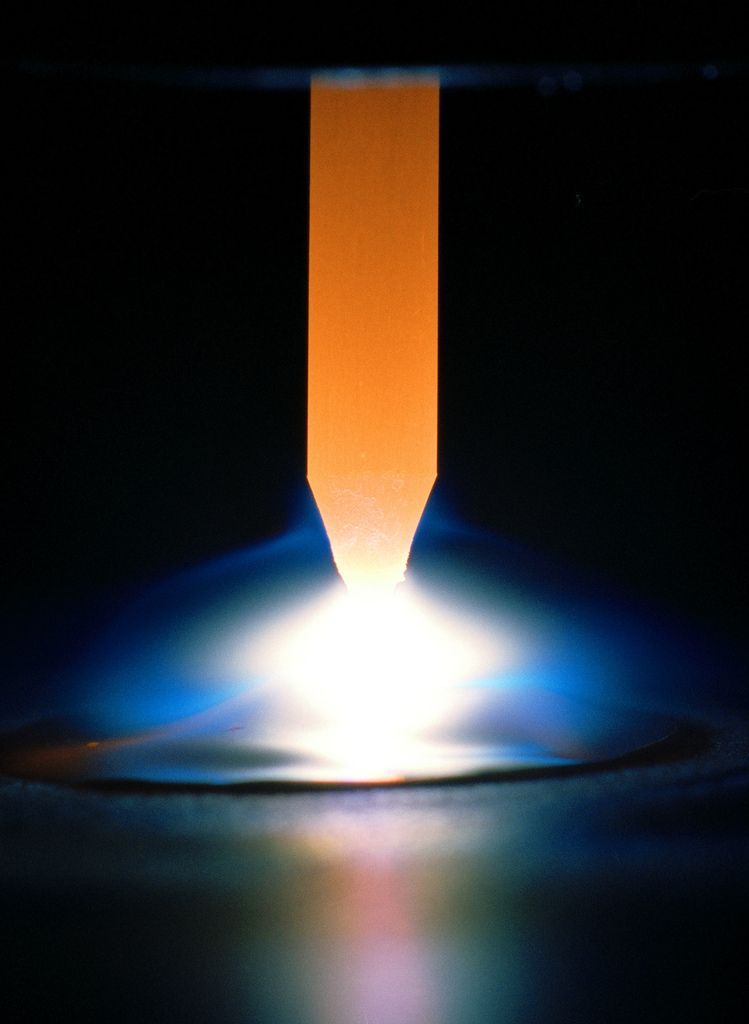

This is pretty much ideal IMO.

This is NO GOOD. Distance from arc is good, but tip of tungsten is indistinguishable from electric arc light. You see that round, blue aura appearing in the photo? That's what you get with clear lenses in unsuitable state for TIG welding.

This is much better, BUT there is way too much arc length (probably was just for demonstration purposes)

This is pretty much ideal IMO.

exnailpounder

- exnailpounder

-

Weldmonger

-

Posts:

-

Joined:Thu Dec 25, 2014 9:25 am

-

Location:near Chicago

I got arc flashed and even sunburned sometimes doing aluminum with my AD properly set. That stopped when I attached a piece of leather to the bottom of my hood that blocks the rays from bouncing off the table or light colored clothing and hitting my face. Keeps you from getting a neck burn if you forget to button your shirt all the way up too.nelson wrote:Hi all,

I'm new at this. I've been sticking the tungster more than necessary. I will try darkening the shade. I've had it around 10 or so. I'm thinking darker may help me see the tip better???

I guess concurrently is this a safety issue? I've had this helmet for 10 years doing Flux core until 2 weeks ago when I stuck my tip in the TIG arts. In using this helmet I've never had an issue with my eyes. I was concerned at first since when striking the arc I could see a bit of flash before it darkened...maybe a few milliseconds.

should I set it for 11? I've heard I would get a scratchy sensation in the eyes especially when going to sleep? Wives tale?

Many thanks!

You have to play with the settings in your hood. It's not like you can just set it and forget it, increased amps cause brighter rays. AC causes brighter rays so you have to adjust your hood. Maybe try a cheater lens while your at it.

If your eyes feel like they have sand in them, your obviously getting flashed from somewhere. A good AD will protect you at all times from flash but you still have to adjust your shade setting.

Ifyoucantellmewhatthissaysiwillbuyyouabeer.

Thanks,

I'll be practicing outside if the breeze let's up. Really nice photos! Thanks!

Had a leak on the inlet of the welder...5cfh. I shouldn't expect much difference except less wasted gas.

I was a machinist in the 70s getting thru school. Now I'm an engineering dept, tool making dept. And maint. Dept....Back in the day at Leeds and Northrup we solids machinists had great respect for welders. Hopefully I can become a passable one.

Keep 'em Flying !

I'll be practicing outside if the breeze let's up. Really nice photos! Thanks!

Had a leak on the inlet of the welder...5cfh. I shouldn't expect much difference except less wasted gas.

I was a machinist in the 70s getting thru school. Now I'm an engineering dept, tool making dept. And maint. Dept....Back in the day at Leeds and Northrup we solids machinists had great respect for welders. Hopefully I can become a passable one.

Keep 'em Flying !

Stone knives and bearskins.....and a NEW EVERLAST 164SI !!!

That's my newly shared work welder.

At home I got a Power Tig 185 DV. Nice, but no plasma cutting... Nice tight arc after a second.

That's my newly shared work welder.

At home I got a Power Tig 185 DV. Nice, but no plasma cutting... Nice tight arc after a second.

Return to “Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities