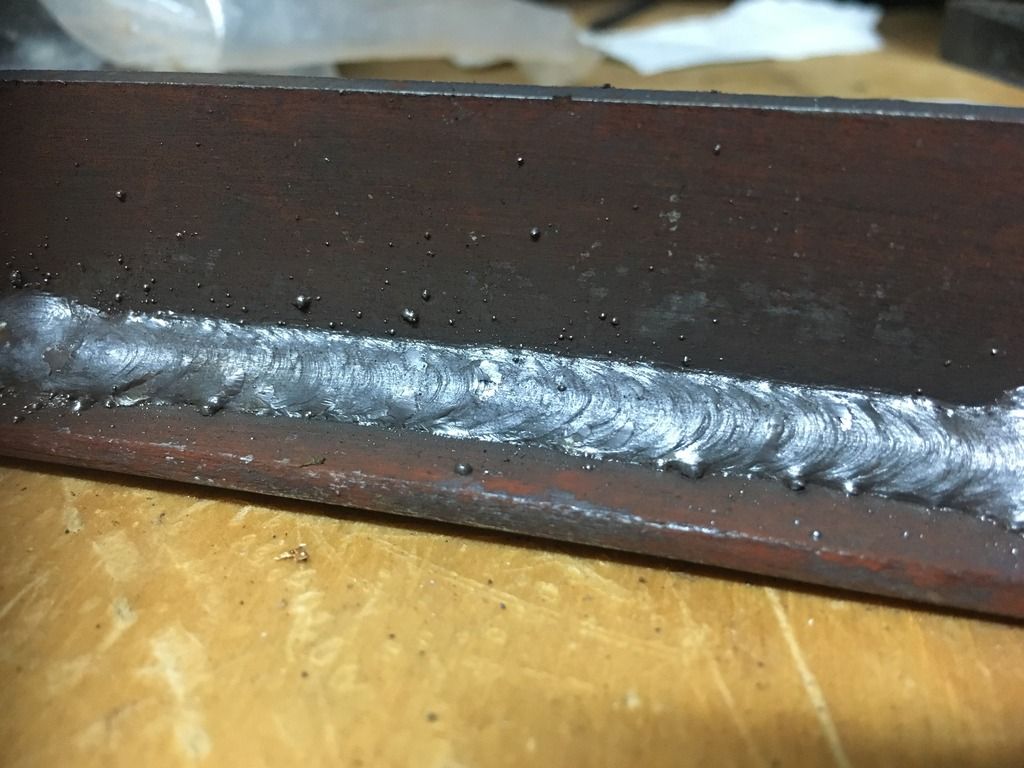

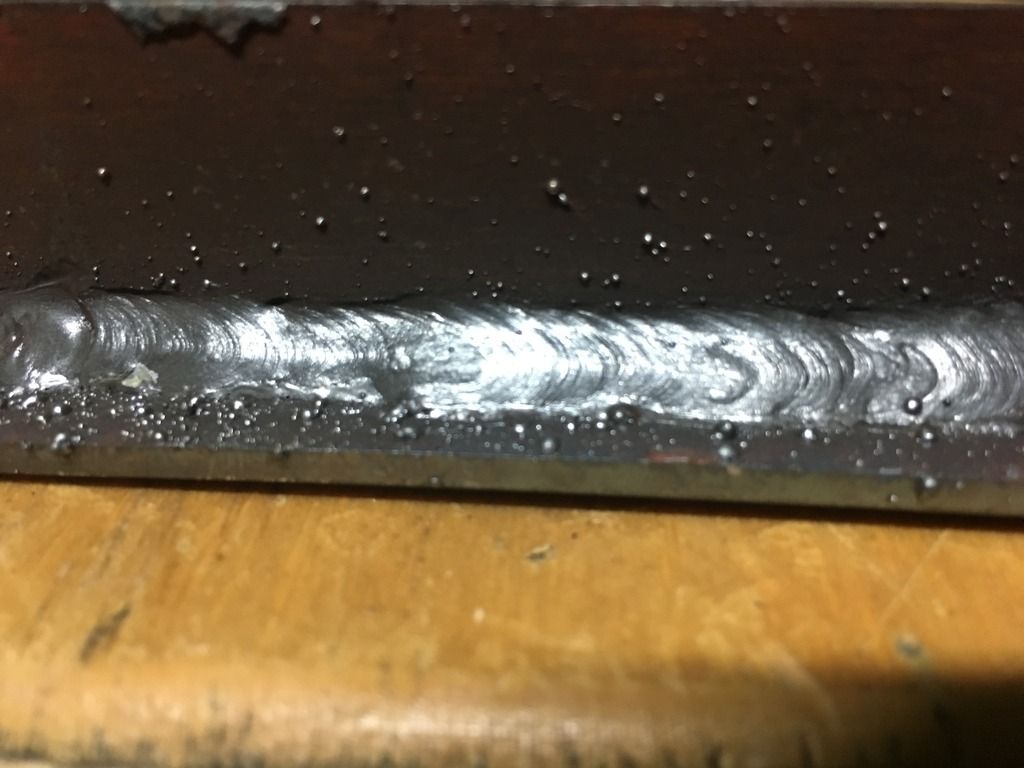

Probably not the best view

Spatter can be caused by too much or not enough wire speed. I am looking at the fillet weld and undercut as an indication of too little wire speed. Pure and simple.Brettm357 wrote:3mm plate 1/8 inch not sure on voltage its on number 4 out of 6

If i turn wire speed up will that create more spatter and do i have too much now

Return to “Mig and Flux Core - gas metal arc welding & flux cored arc welding”