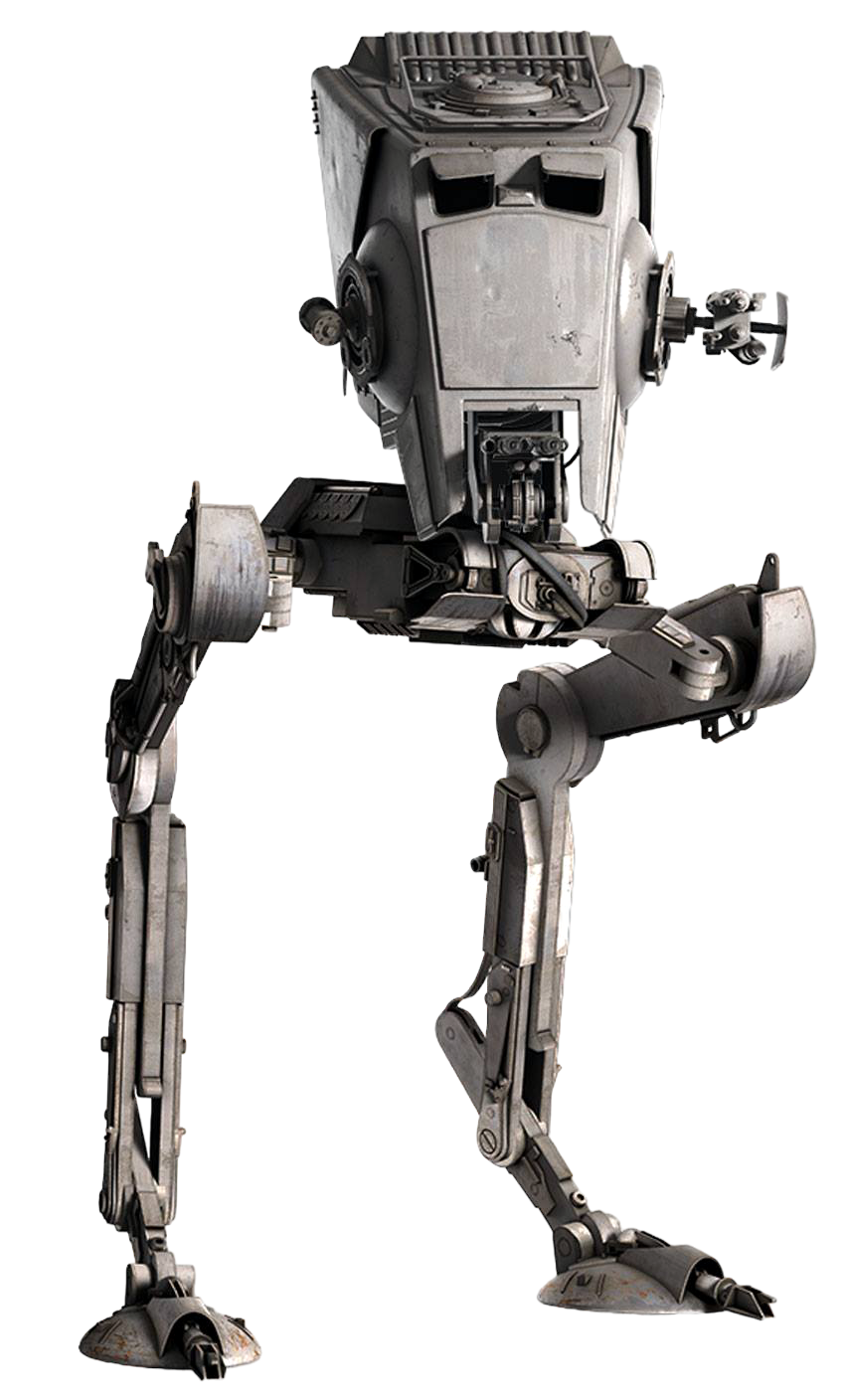

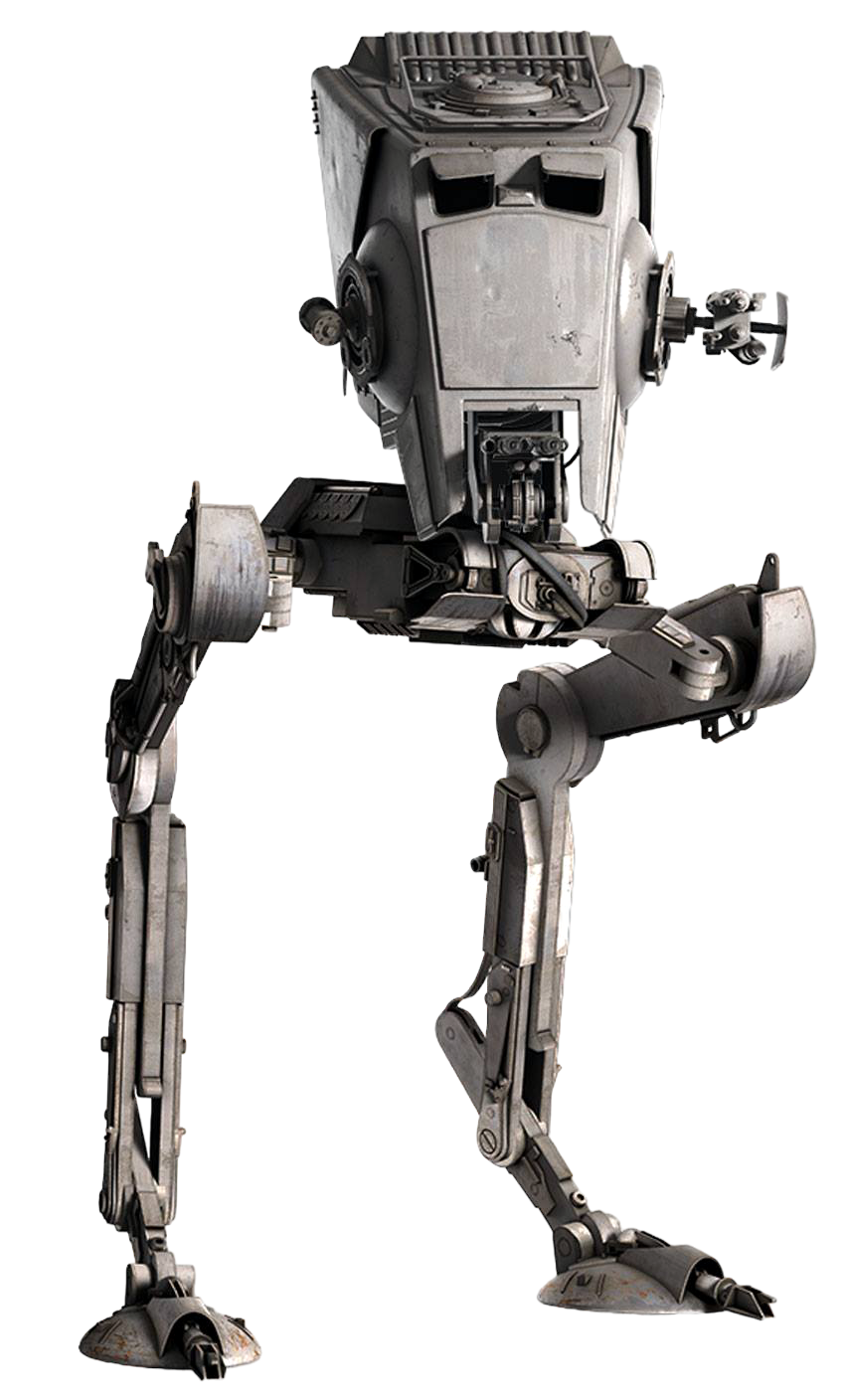

My son picked the project and we are working together as he learns woodworking, welding, painting, etc. we are making a chair for his desk that will look like an AT-ST walker from Star Wars.

Pics are below. I planned on painting the whole thing military gray but my wife thinks the shiny legs look cool and we should pave them. What do you guys think? We will add gears and joints first, but paint gray or just rattle can clear coat the shiny metal?

What welding projects are you working on? Are you proud of something you built?

How about posting some pics so other welders can get some ideas?

How about posting some pics so other welders can get some ideas?

- Attachments

-

- 1F03AA60-5BDF-40D0-A392-664A664DF47E.jpeg (67.38 KiB) Viewed 1189 times

Hobbyist MIG welder with 75/25 gas on a Lincoln SP-140 in my garage/workshop/gym/storage space. Very new and still learning.

"Service is the rent you pay for room on this earth" - Shirley Chisholm

"Service is the rent you pay for room on this earth" - Shirley Chisholm

Shiny metal. Hit it with Flood Penetrol to prevent flash rusting. Skip the clear coat. Rattle can paint still needs a primer or mechanical "tooth" for proper adhesion. If you polish it up, and expect it to remain so under the clear, the clear will fail. You'd need to scuff it up somewhat, that in turn wrecks the polish, etc... Or you could have the base powder coated since that would be applied by electro-static charge and high heat. Still will need some light glass beading for adhesion.

I'm new to finishing metal. Do I just brush on the Flood Penetrol? Is it a long term (read: lifelong) solution? I'd rather not spend the money on powder coating. I haven't taken it to a true polish, just to a 40 grit flap disc, is that enough texture?cj737 wrote:Shiny metal. Hit it with Flood Penetrol to prevent flash rusting. Skip the clear coat. Rattle can paint still needs a primer or mechanical "tooth" for proper adhesion. If you polish it up, and expect it to remain so under the clear, the clear will fail. You'd need to scuff it up somewhat, that in turn wrecks the polish, etc... Or you could have the base powder coated since that would be applied by electro-static charge and high heat. Still will need some light glass beading for adhesion.

Thanks in advance

Hobbyist MIG welder with 75/25 gas on a Lincoln SP-140 in my garage/workshop/gym/storage space. Very new and still learning.

"Service is the rent you pay for room on this earth" - Shirley Chisholm

"Service is the rent you pay for room on this earth" - Shirley Chisholm

Cool idea!

I'd personally would try to aim for the 'lived in' look that most StarWars gear has with various white, grey and 'dirty' patches:

And see if you can perhaps add some detailing on the seat section with paint to copy some of the features of the AT-ST 'head'.

Just personal preference.. You do what your son wants

Bye, Arno.

I'd personally would try to aim for the 'lived in' look that most StarWars gear has with various white, grey and 'dirty' patches:

And see if you can perhaps add some detailing on the seat section with paint to copy some of the features of the AT-ST 'head'.

Just personal preference.. You do what your son wants

Bye, Arno.

- MinnesotaDave

-

Weldmonger

-

Posts:

-

Joined:Sun Oct 27, 2013 10:57 pm

-

Location:Big Lake/Monticello MN, U.S.A.

Cool project

Dave J.

Beware of false knowledge; it is more dangerous than ignorance. ~George Bernard Shaw~

Syncro 350

Invertec v250-s

Thermal Arc 161 and 300

MM210

Dialarc

Tried being normal once, didn't take....I think it was a Tuesday.

Beware of false knowledge; it is more dangerous than ignorance. ~George Bernard Shaw~

Syncro 350

Invertec v250-s

Thermal Arc 161 and 300

MM210

Dialarc

Tried being normal once, didn't take....I think it was a Tuesday.

That was totally our original intent. I used the flap pads to make it smoother for 'living' in the chair. But it came out looking pretty cool. Our plan is to go to a scrap yard and scrounge for a variety of things to add to the legs and body. Transmission gears and small hydraulics for the leg joints, something for bigger feet, gun turrets on either side, and who knows what else. We will paint the box too. Maybe either the whole thing military gray with some 'battle scars' or the shiny silver legs and something different for the body (black, military gray, shiny silver). Just not sure yet.Arno wrote:Cool idea!

I'd personally would try to aim for the 'lived in' look that most StarWars gear has with various white, grey and 'dirty' patches:

And see if you can perhaps add some detailing on the seat section with paint to copy some of the features of the AT-ST 'head'.

Just personal preference.. You do what your son wants

Bye, Arno.

Hobbyist MIG welder with 75/25 gas on a Lincoln SP-140 in my garage/workshop/gym/storage space. Very new and still learning.

"Service is the rent you pay for room on this earth" - Shirley Chisholm

"Service is the rent you pay for room on this earth" - Shirley Chisholm

Return to “Welding Projects - Welding project Ideas - Welding project plans”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities