Any of you guys ever mess with SolidWorks, or a similar 3d CAD program? I've been bored as heeellllll lately, and have been messing about quite a bit, with different things such as Weldments, and Sheet Metal design. A lot of the stuff you can do with it is cool, actually, some of it is incredible. You also have the option to export it as a CAD/CAM file for a machining outfit, or make an isometric drawing out of it with dimensions so you can just put it in a folder in case you ever have to make another one. You can add in weld beads, or set dimensions to include a weld gap if you don't want a butt joint, and some of the different features generate a 'cut list' with the length and #of pieces to make the project. Granted, to purchase a copy out right is a few thousand dollars, but you can find it for free if you know where to look (not that I encourage that or anything... I have a student license version)

Just curious as to whether anyone else takes advantage of the technology available when planning/designing a project. I can't imagine how much time went in to making some of the features that you can utilize, especially the math involved with something like a spline, when an engineer had to design all of that stuff manually. It's amazing how different the way things are/can be done now with the advent of modern computing.

What welding projects are you working on? Are you proud of something you built?

How about posting some pics so other welders can get some ideas?

How about posting some pics so other welders can get some ideas?

Personally I use AutoCAD Inventor user (I'm a Certified AutoCAD and Inventor user with about 20 years expierence), it is a great tool and has been a huge help with design and stress analysis.GreinTime wrote:Any of you guys ever mess with SolidWorks, or a similar 3d CAD program? I've been bored as heeellllll lately, and have been messing about quite a bit, with different things such as Weldments, and Sheet Metal design. A lot of the stuff you can do with it is cool, actually, some of it is incredible. You also have the option to export it as a CAD/CAM file for a machining outfit, or make an isometric drawing out of it with dimensions so you can just put it in a folder in case you ever have to make another one. You can add in weld beads, or set dimensions to include a weld gap if you don't want a butt joint, and some of the different features generate a 'cut list' with the length and #of pieces to make the project. Granted, to purchase a copy out right is a few thousand dollars, but you can find it for free if you know where to look (not that I encourage that or anything... I have a student license version)

Just curious as to whether anyone else takes advantage of the technology available when planning/designing a project. I can't imagine how much time went in to making some of the features that you can utilize, especially the math involved with something like a spline, when an engineer had to design all of that stuff manually. It's amazing how different the way things are/can be done now with the advent of modern computing.

From a thought in your brain, to a 3D model to a proto-type or part can be pretty quick

I weld stainless, stainless and more stainless...Food Industry, sanitary process piping, vessels, whatever is needed, I like to make stuff.

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

ASME IX, AWS 17.1, D1.1

Instagram #RNHFAB

GreinTime

- GreinTime

-

Weldmonger

-

Posts:

-

Joined:Fri Nov 01, 2013 11:20 am

-

Location:Pittsburgh, PA

I have no experience whatsoever as far as professional training or anything, just messing about because I have too much time on my hands right now. The good news is, a friend is wiring a 50a service at my garage, and another mutual friends garage in exchange for future services rendered (aka they need me to weld things for them, and have the skills to do a job that I'm perfectly capable of, but would rather let the sparky take care of  ) So I'll be able to start welding again now that I'm back out at school, and can start making some of the things I've been working on. I'm going to design a cart for the PowerTIG 250ex and the associated water cooler as my actual first "project" with it, not just finish welding his wheel tubs, and modifying his valve cover so he can use AN lines for his breathers.

) So I'll be able to start welding again now that I'm back out at school, and can start making some of the things I've been working on. I'm going to design a cart for the PowerTIG 250ex and the associated water cooler as my actual first "project" with it, not just finish welding his wheel tubs, and modifying his valve cover so he can use AN lines for his breathers.

And yes, 3D printing is incredible. The Amputee Coalition recently did a humanitarian project in Sudan, I think it was, where they used a bunch of 3D printers to make a bunch of arms for people (since I guess limb loss is fairly common due to tribal conflicts.) Think about though... they made whole arms for people to use... with a printer!!!!

And yes, 3D printing is incredible. The Amputee Coalition recently did a humanitarian project in Sudan, I think it was, where they used a bunch of 3D printers to make a bunch of arms for people (since I guess limb loss is fairly common due to tribal conflicts.) Think about though... they made whole arms for people to use... with a printer!!!!

#oneleggedproblems

-=Sam=-

-=Sam=-

I've experimented with SolidWorks but the 'legal licensing' is a big turn off for me.

Instead, what I am using is completely license free including the operating system.

My home computing system uses my 52" LCD television as a monitor.

I use a wireless keyboard and mouse and operate from my leather couch.

The computer is a FoxConn Nano-PC that is no bigger than an old VHS tape.

(and is mounted to the side of the television stand.)

128Gig solidstate drive and 4Gigs of ram. (boot-up time = 4sec. total shutdown = 4sec.)

http://www.foxconnchannel.com/LatestPro ... x?T=NanoPC

I use Ubuntu LinuxCNC as my operating system with the CNC application.

(LinuxCNC used to be called EMC2 before the legal issues with the name.)

http://www.linuxcnc.org/

I use a program called Blender to create the actual objects that can output to a 3D printer.

http://www.blender.org/

http://www.blendernation.com/2007/12/27 ... pdf-guide/

http://www.scribd.com/doc/88893105/Blen ... -Modelling

BTW - Watching youtube tutorials on a 52" LCD television is the only way to go.

https://www.youtube.com/results?search_ ... x+cnc&sm=3

Instead, what I am using is completely license free including the operating system.

My home computing system uses my 52" LCD television as a monitor.

I use a wireless keyboard and mouse and operate from my leather couch.

The computer is a FoxConn Nano-PC that is no bigger than an old VHS tape.

(and is mounted to the side of the television stand.)

128Gig solidstate drive and 4Gigs of ram. (boot-up time = 4sec. total shutdown = 4sec.)

http://www.foxconnchannel.com/LatestPro ... x?T=NanoPC

I use Ubuntu LinuxCNC as my operating system with the CNC application.

(LinuxCNC used to be called EMC2 before the legal issues with the name.)

http://www.linuxcnc.org/

I use a program called Blender to create the actual objects that can output to a 3D printer.

http://www.blender.org/

http://www.blendernation.com/2007/12/27 ... pdf-guide/

http://www.scribd.com/doc/88893105/Blen ... -Modelling

BTW - Watching youtube tutorials on a 52" LCD television is the only way to go.

https://www.youtube.com/results?search_ ... x+cnc&sm=3

- Attachments

-

- Precision Modelling.jpg (86.81 KiB) Viewed 4810 times

-

- Nano-PC-AT7304-foxconn.jpg (107.75 KiB) Viewed 4810 times

I use Pro Engineer at work ....Most of our customers no longer use paper drawings , choosing to use 3D models for manufacturing purposes....All our fabricator/welders have PC's so they can access the models..

Also have access to AutoCad and SolidWorks.....AutoCad i can use fairly well , but SolidWorks is not something that i have used beyond half an hours play around with it...

Also have access to AutoCad and SolidWorks.....AutoCad i can use fairly well , but SolidWorks is not something that i have used beyond half an hours play around with it...

Murex 353is TransTig

Esab Aristo Mig 4001i Pulse

Murex 406s Transmig

Esab Aristo Mig 4001i Pulse

Murex 406s Transmig

- roberthall

-

New Member

-

Posts:

-

Joined:Wed Feb 26, 2014 1:01 am

-

Location:Utah

I use solid works.

It's great for documenting a physical object, but I am not an expert.

It takes me longer to input a welding cart than it does to make one.

It's great for documenting a physical object, but I am not an expert.

It takes me longer to input a welding cart than it does to make one.

I purchased BendTech Pro w/ Sheet Metal Module and Header Design Module a few months back when it was on sale. Got all three for $350. Don't plan to make too much stuff, I really just wanted to wet my beak into the world of tube bending/fabricating so that in 10yrs I can build my own roll cage.

Werkspace - that program, Blender, looks interesting. I'm a fan of open source software. I too have a computer with EMC2, but I have mine because of a CNC-project, but some cad software wouldn't hurt  . Is Blender really a useful tool? (I've downloaded it, but haven't had time to learn how to use it, yet).

. Is Blender really a useful tool? (I've downloaded it, but haven't had time to learn how to use it, yet).

Personally, I've used Autodesk Inventor for some years now. I started out with AutoCAD 2000, but for complex work, Inventor is just way faster and easier. I make custom torsion tubes for a guy, who uses Geomagic Design (originally called Alibre Design). Geomagic is not as "heavy" as Inventor, and not as "polished", but still pretty cool. I've been thinking about changing over to Geomagic. There's a lot of tools in Inventor that I don't use, so it seems like a waste. I like to keep things as simple as possible.

At our paper-casting (is it called that in english ) company, they use solid works, and the engineer the adds on some work with Delcam Power Shape, to make things run smooth with the CNC work.

) company, they use solid works, and the engineer the adds on some work with Delcam Power Shape, to make things run smooth with the CNC work.

Personally, I've used Autodesk Inventor for some years now. I started out with AutoCAD 2000, but for complex work, Inventor is just way faster and easier. I make custom torsion tubes for a guy, who uses Geomagic Design (originally called Alibre Design). Geomagic is not as "heavy" as Inventor, and not as "polished", but still pretty cool. I've been thinking about changing over to Geomagic. There's a lot of tools in Inventor that I don't use, so it seems like a waste. I like to keep things as simple as possible.

At our paper-casting (is it called that in english

I've been using SolidWorks for about four years now, and it is an invaluable tool. Designing something and working out most of the 'kinks' before you ever start cutting metal saves a lot of time and wasted material. Unfortunately, it is expensive (starting cost is around $5000). For us, it's been an investment that has paid for itself many times. However, the old method of a pencil, paper and a tape measure still works, and only costs a few dollars.

Search Weldments or SolidWorks on YouTube for a lot of great training videos. Good Luck and happy designing!

Search Weldments or SolidWorks on YouTube for a lot of great training videos. Good Luck and happy designing!

The world is full of people smarter than me.

I have tried DraftSight for shop drawings, and while I am no expert, it works for me. (I am desperately trying to advance beyond my freehand sketches of everything I make, but the sketches plus dimensions are very effective. Clients are really pleased when you sketch up an idea, run a tape over their site or structure, and hand them a dimensioned daft plan in about 3 minutes. Scratch in a dollar sign, and you always end up with the job. With a little bit of milling in my work now, neater drawings are a logical step.)

Blender is available for Windows as well as UNIX based systems.

PS I have followed some of his threads, and I must say I find that Werkspace gentleman a very interesting forum member. It would be handy, I think, to have him living no too far away. Thanks for your contributions.

Blender is available for Windows as well as UNIX based systems.

PS I have followed some of his threads, and I must say I find that Werkspace gentleman a very interesting forum member. It would be handy, I think, to have him living no too far away. Thanks for your contributions.

A 2013 publication, CAD for the Workshop, by Neill Hughes, Crowood, Wiltshire, (a part of the Crowood Metalworking Guides), classes SolidWorks as one of the Mid-band Commercial Products (read, expensive for small shops) that "are excellent parametric, feature-based 3D solid modellers, with a comprehensive suite of product development tools." page 70

The others are Inventor, NX, IronCAD, and Creo.

The only open source product they tentatively nominate is BRL-CAD.

Perhaps we should tell Mr Hughes about Blender?

The others are Inventor, NX, IronCAD, and Creo.

The only open source product they tentatively nominate is BRL-CAD.

Perhaps we should tell Mr Hughes about Blender?

Tassie Dave

- Tassie Dave

-

Active Member

-

Posts:

-

Joined:Wed Sep 03, 2014 2:04 am

-

Location:Tasmania

Any recommendations for a Mac user. Bear in mind its for non commercial use. Any ideas gratefully accepted.

I have an

Esab LHQ 150

Pro Weld TC256 ACDC multi process Tig Cut MMA

WeldSmart Mig 200IGBT Mig Tig MMA and spool gun

Esab LHQ 150

Pro Weld TC256 ACDC multi process Tig Cut MMA

WeldSmart Mig 200IGBT Mig Tig MMA and spool gun

Negativ3

- Negativ3

-

Active Member

-

Posts:

-

Joined:Fri Aug 22, 2014 5:25 am

-

Location:Southern Thailand

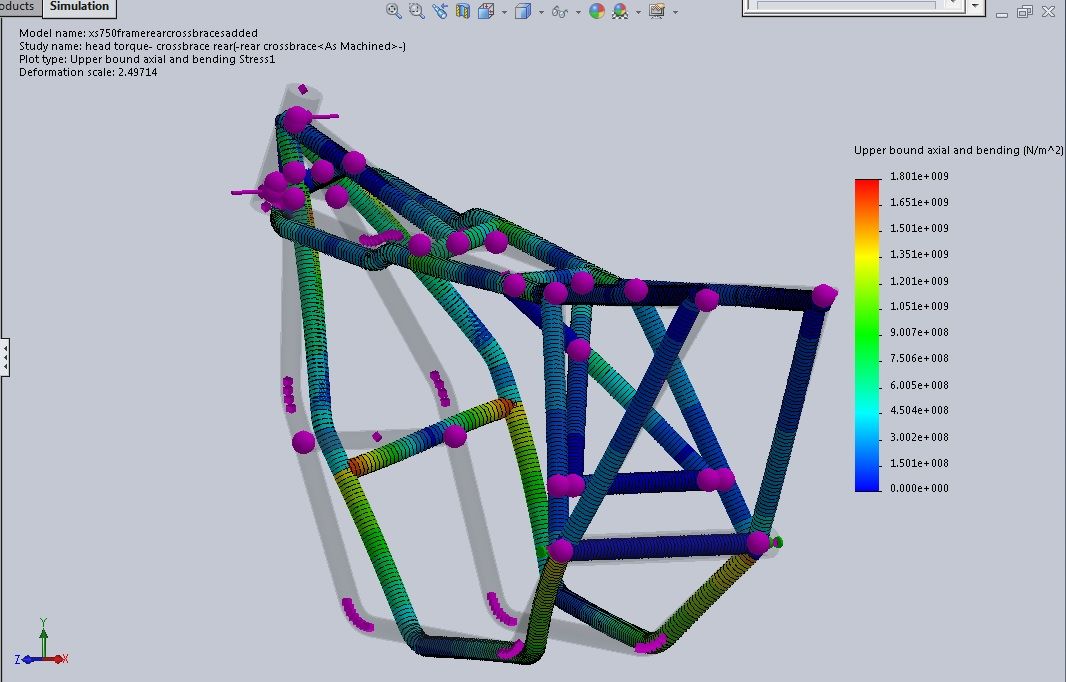

I use Solidworks as part of my job and find it a fantastic tool for developing ideas and testing.

The weldments and sheet metal tools are something I have only recently started using but they are worth the time to learn.

Steep learning curve with hours to learn more advanced features required.

Layout drawing with cut-list automatically generated.

Final render

About 1 hour of time to draw it up.

The weldments and sheet metal tools are something I have only recently started using but they are worth the time to learn.

Steep learning curve with hours to learn more advanced features required.

Layout drawing with cut-list automatically generated.

Final render

About 1 hour of time to draw it up.

Roast beef and Yorkshire pudding is my personal signature dish.

Stupid questions are better than stupid mistakes.

Stupid questions are better than stupid mistakes.

Return to “Welding Projects - Welding project Ideas - Welding project plans”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities