Cut out the damaged section of flange,

prepped a new piece of material to go back in,

tacked the new material in place,

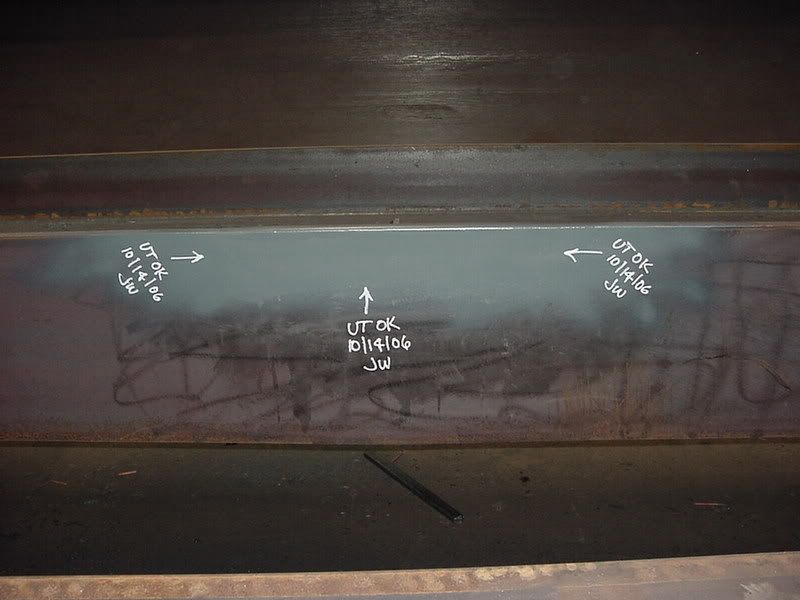

welded one side, back gouged to sound material from the other side and welded, ground the area to appear seamless, inspected the area with ultrasonics to ensure soundness, added a rust preventative coating over the freshly ground material.