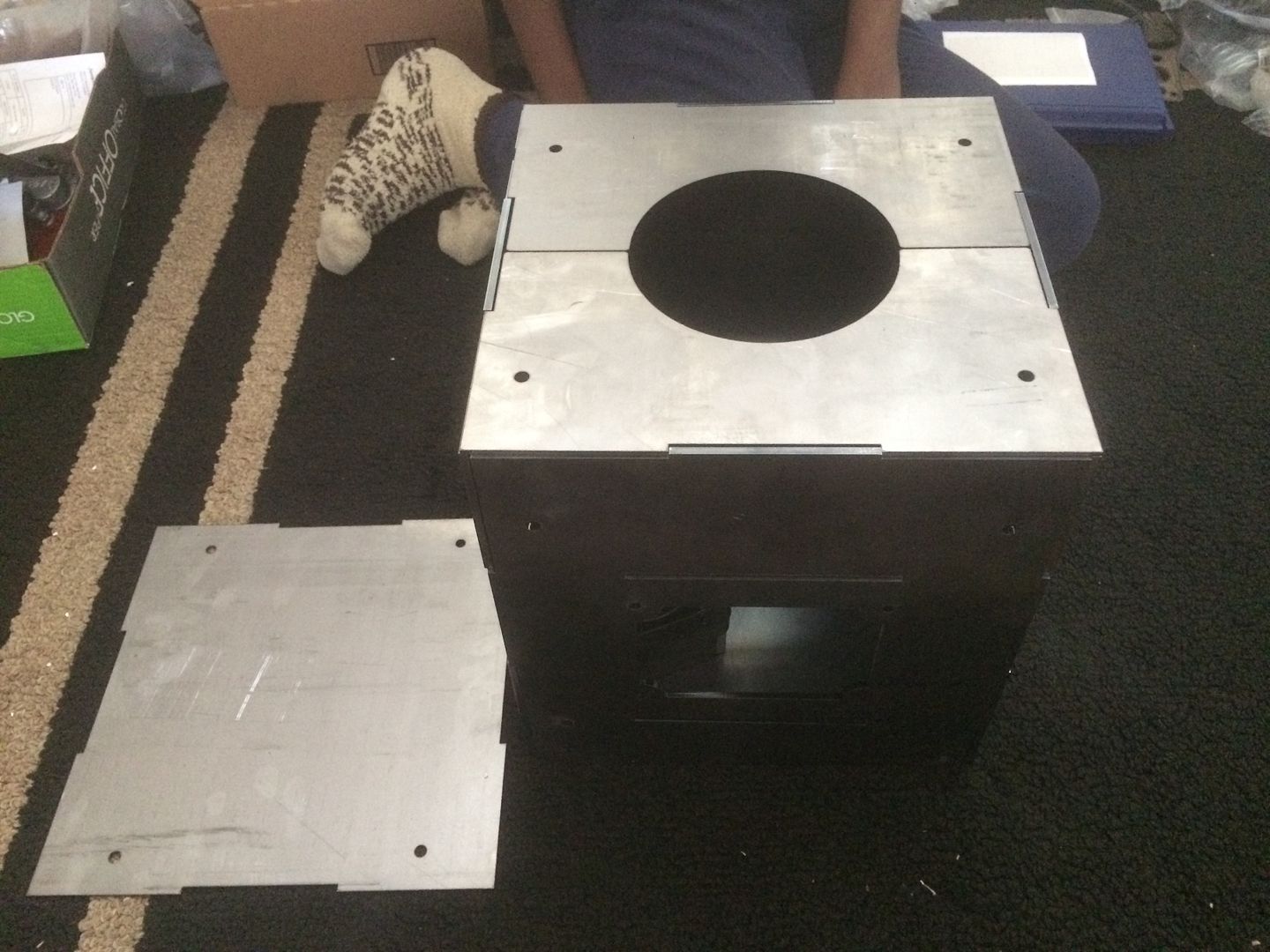

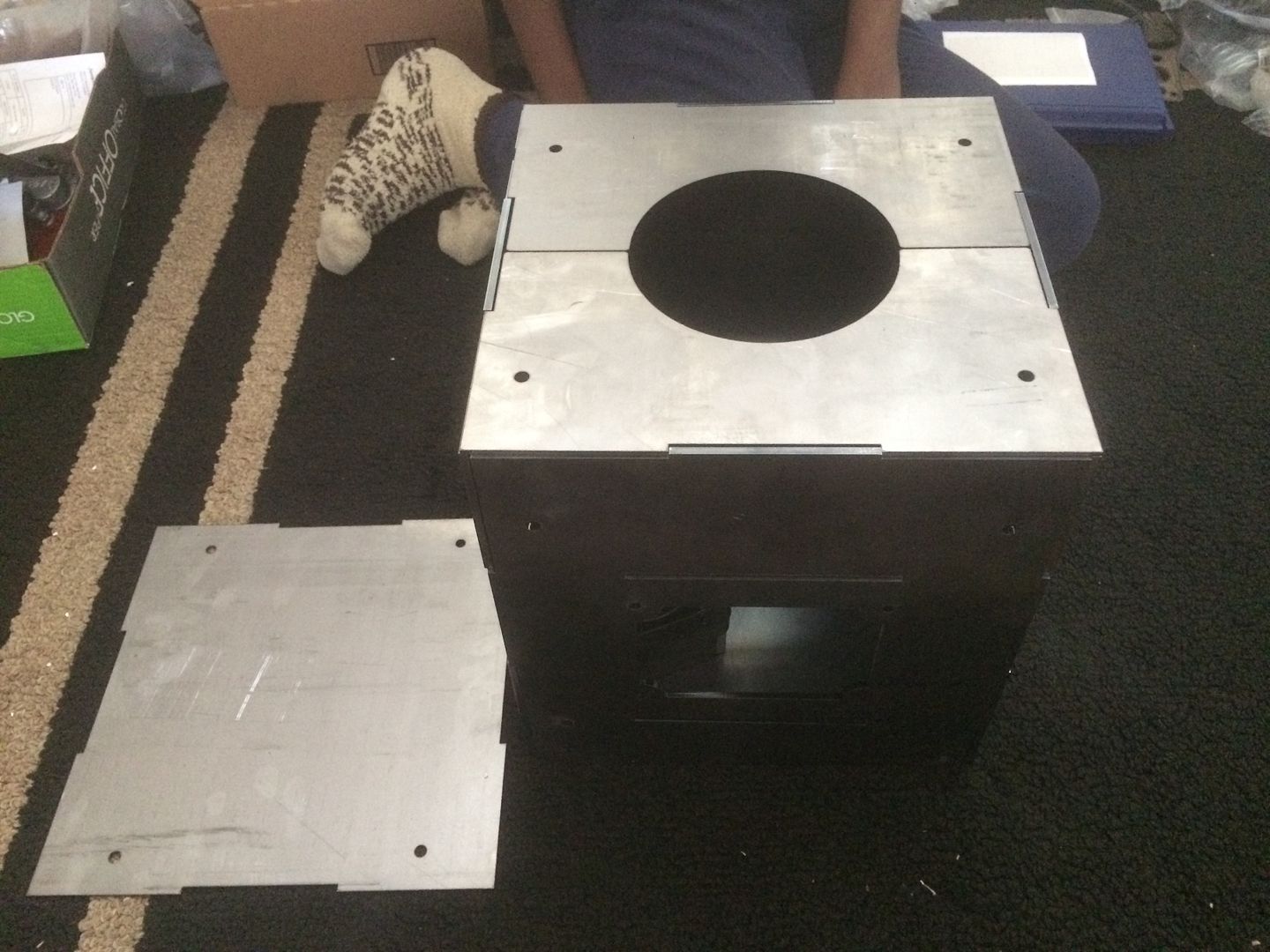

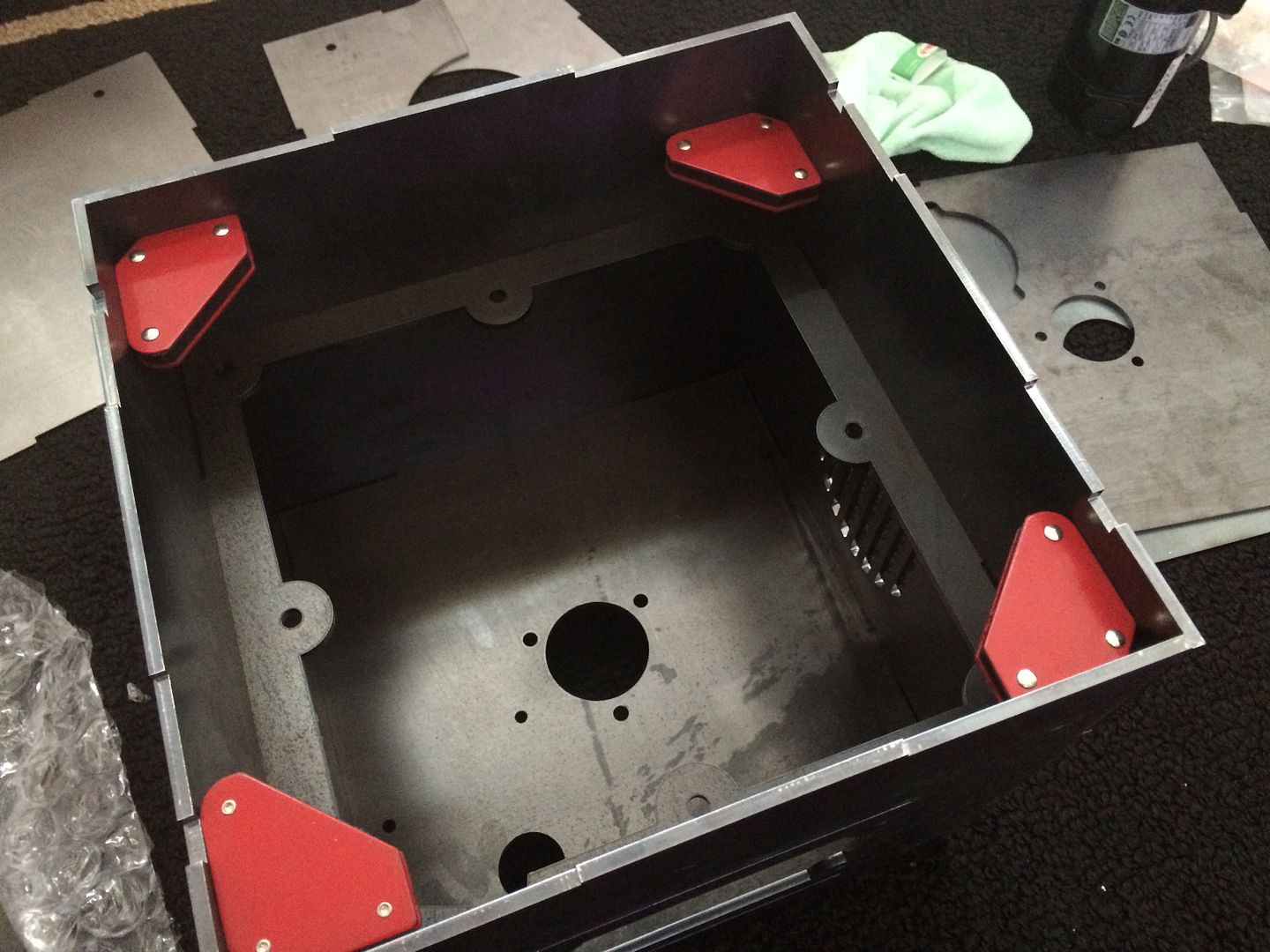

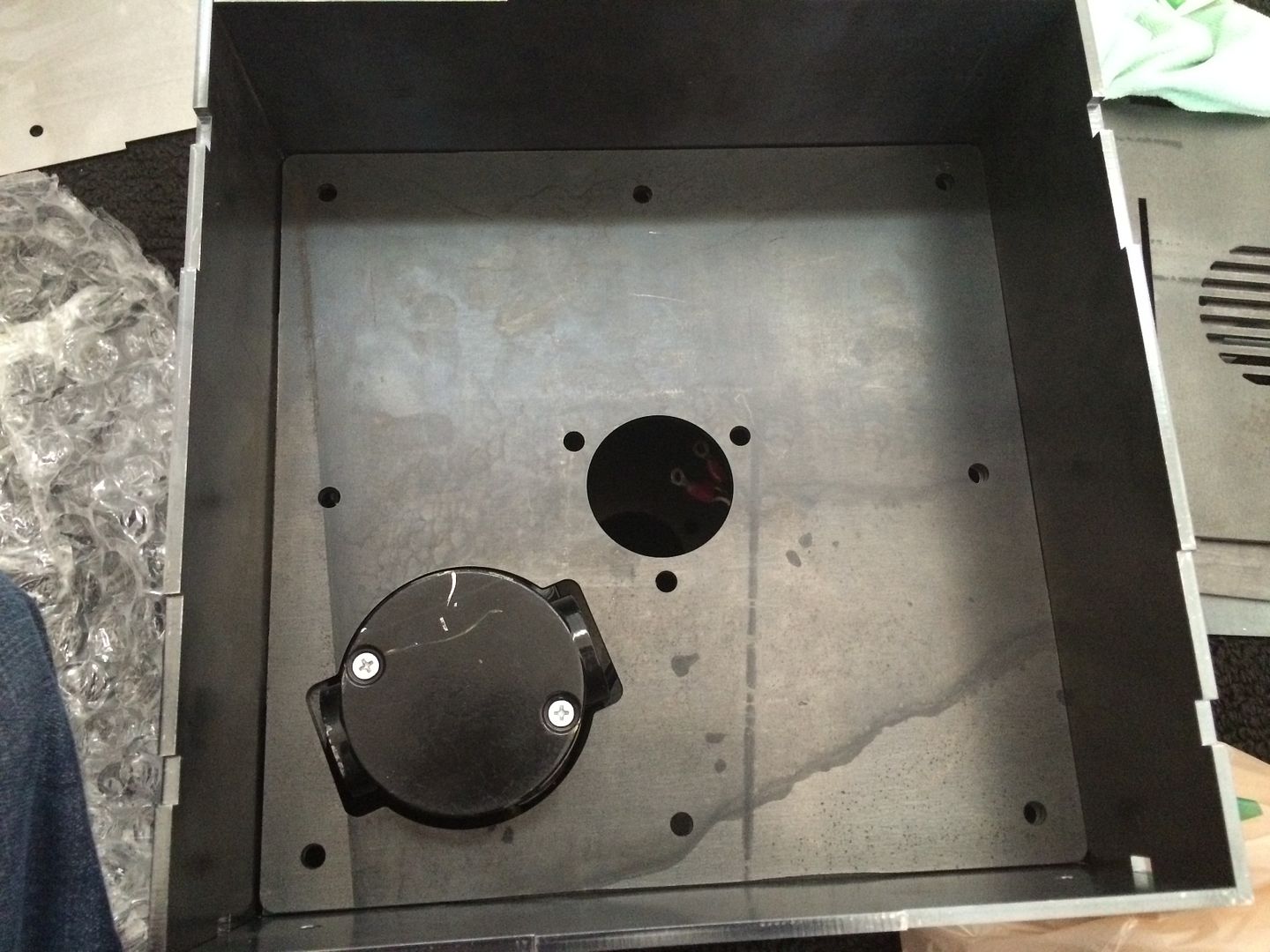

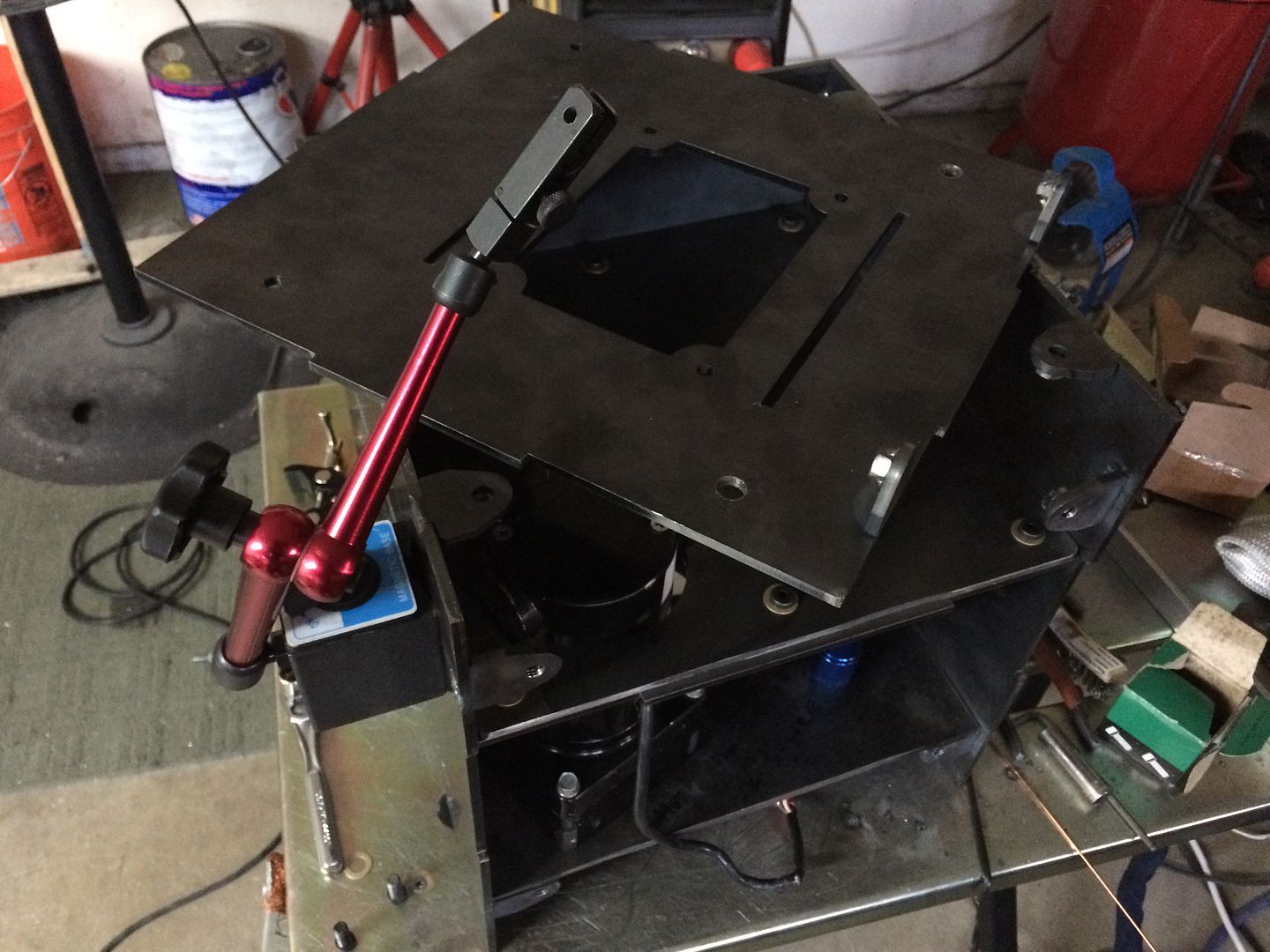

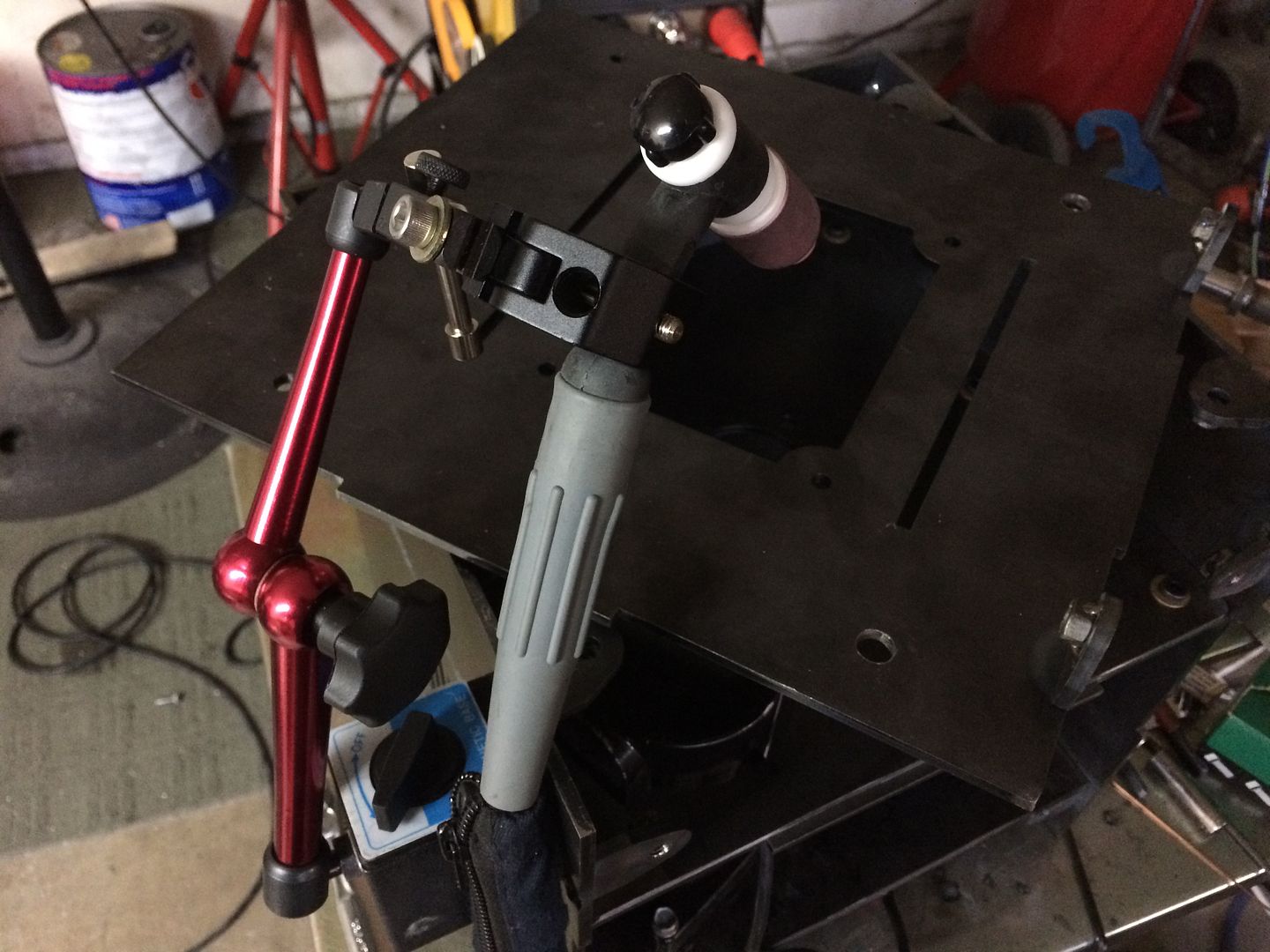

the piece on the floor, is another cover, to cover the gears/chain or belt etc, that will be on the side of the enclosure that is on the floor...

thank you, stitches are irritating the heck outta me, but all went well with last surgery... now doing best i can to try to move in a positive direction and keep doing so... body took a beating through all of the treatment etc and lots of pain etc, left over... but cancer free at this point, so no complaints... life is for the living and i intend to do the best i can at not taking any life left for granted...Rick_H wrote:Looks awesome buddy, I finally picked up a chuck so you have given me a lot of inspiration on building a table. Wish I had access to a waterjet or CNC plasma thought, love to whip up a design in AutoCAD and knock it out.

Im planning my design now, been thinking of making is so I could quickly pull the chuck off and mount it to the side as well more like a roll out type wheel since I do a lot of pipe..still figuring things out.

Good luck with your surgery!

thank you...motox wrote:very cool project!

craig

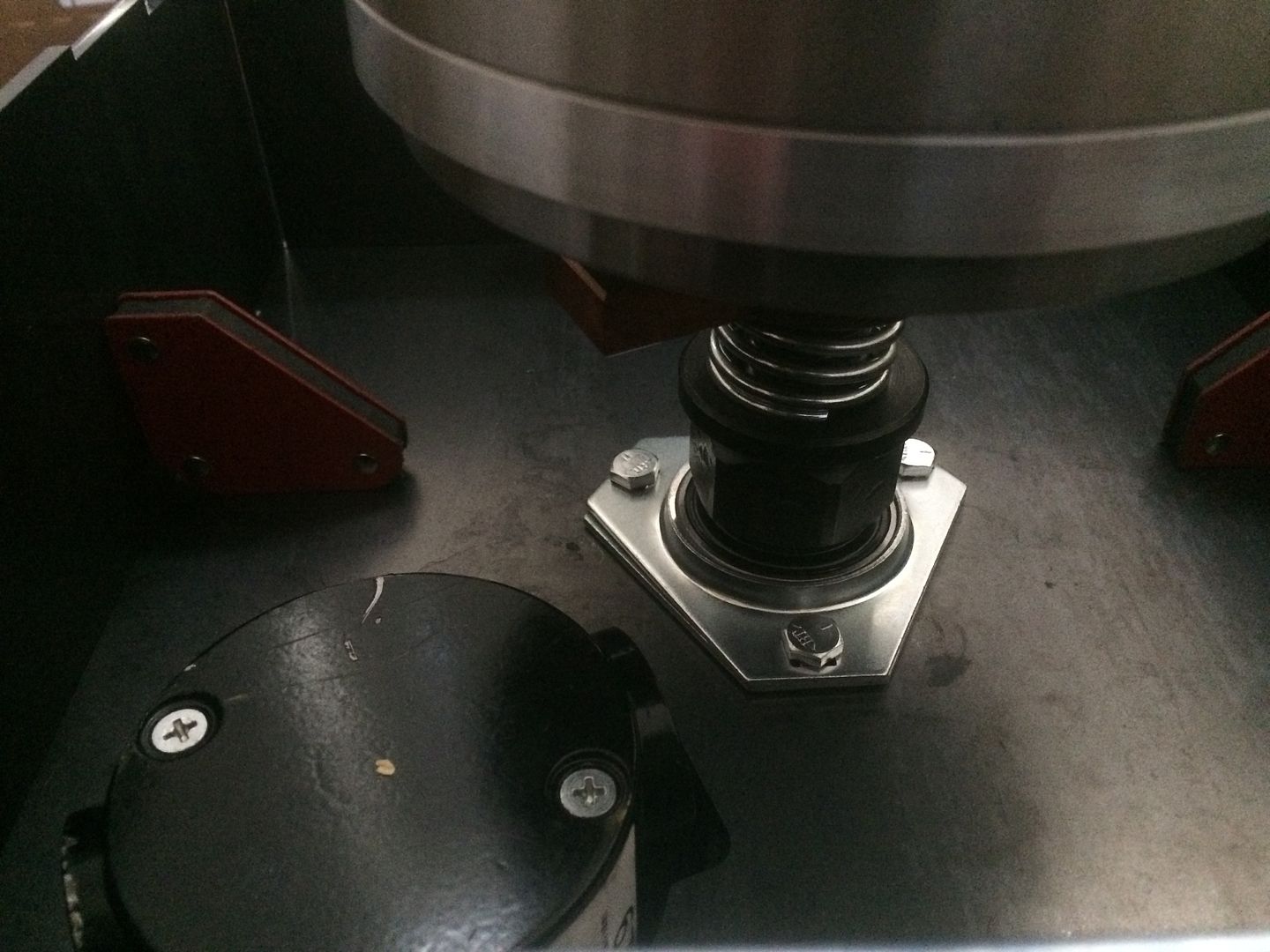

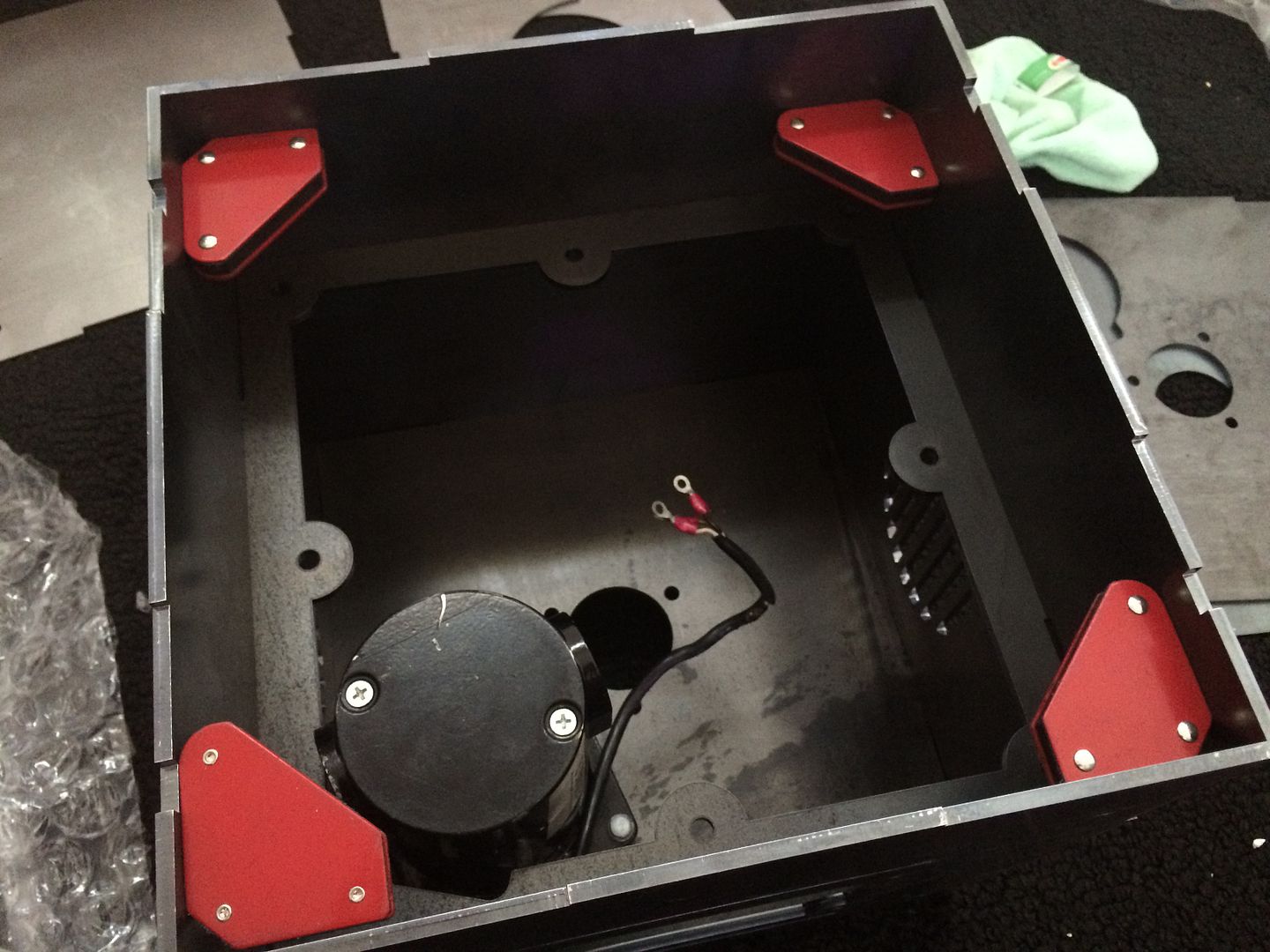

thank you! waiting on some bolts to show up today for the odd 1/4-28 the motor uses to mount... then ill get to trying to wire this up... thank you so much for taking the time to write, also.. understand dealing with back pain and issues with that as well.. wish you the best... and glad i could be of some inspiration, thats the idea for me... i am not confident at times in what i do... and the encouragement does help...stan3leyD wrote:Hi, I wish you the best on your recovery. I myself have been through to many surgeries, but you sound like you are on the right path now.

What a great design, and fabrication job you are doing; kinda thinking I better start looking around for pieces parts for my own. I didn't pay attention to your time line while reading this, got to page 5 anticipating the end of the story and...

Well I can't wait to see it finished.

It is tough for me to sit in front of a computer due to my failed back fusions, so I stream you tube into my room to watch on the TV. Your quality work and winning attitude inspired me to write.

Thanks for your contribution.

Stan

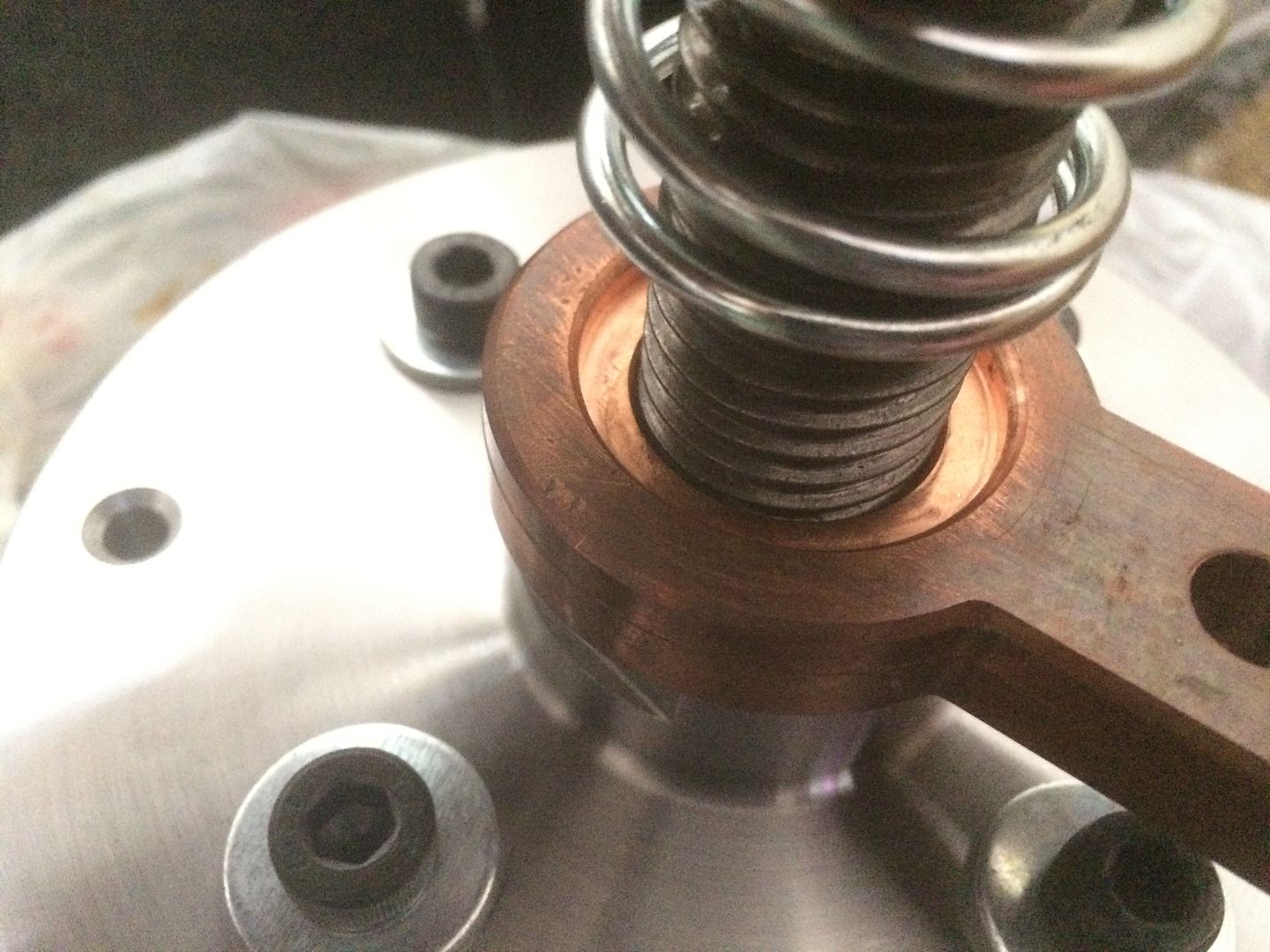

thank you... i am not a shop or anything like that... i more or less just give things my best shot... and people typically like it or often ask me to help with their project... most of what i do, is motivated more in that i could not afford to be into or try so many different things, if i dont work hard or do what i can do, myself, to facilitate it... I had been watching Jody's videos for years and am so glad I started tig welding... cant wait to get this thing up and running, so, i can get a ton or practice in.... i have a bunch of crazy ideas... it rarely stops... lol...motox wrote:your detail on fit up is exceptional.

I'm sure your everyday custom work

is as well.

I'm really enjoying they build.

craig

thank you... will be testing this out, hopefully this week... along with my water cooler setup...maker of things wrote:Very nice work. Looking forward to seeing the finished project.

Return to “Welding Projects - Welding project Ideas - Welding project plans”