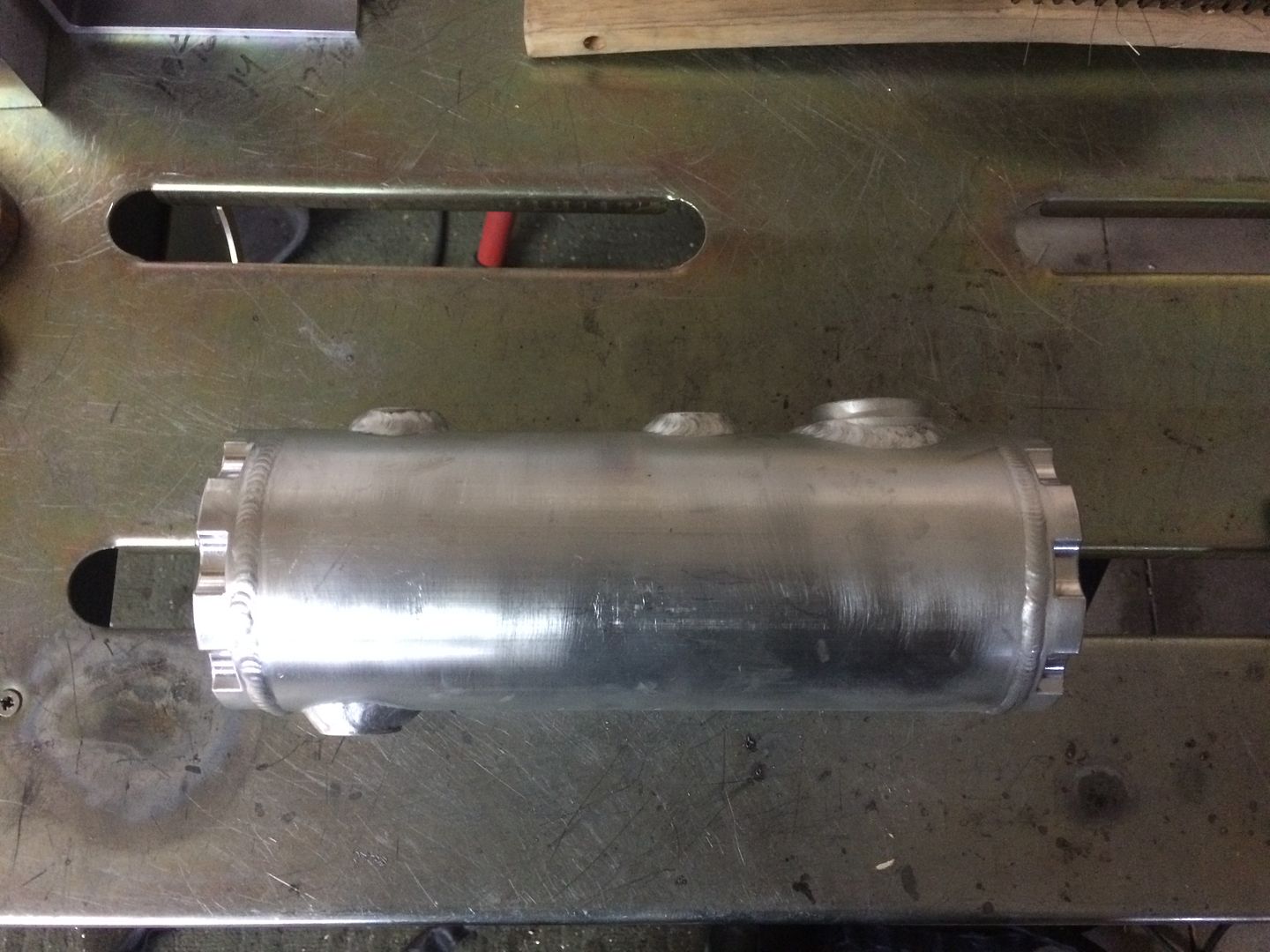

i thought about that too... i will bevel the rest of the tanks i make with these end caps, and if i do more of them, ill make the end caps set in on the tank ends... and make the caps bolt on... i am doing a custom tank for a friend like that... and should have done them all, it is a pain to smooth all these welds out... in my current (painful) state...Poland308 wrote:If you know ahead of time you are going to grind it flush then it's a good idea to prep it to an open but weld. I.E. a gap and also bevel back the parts as mush as you reasonably can. This will leave lots of weld material even after you blend in the top.

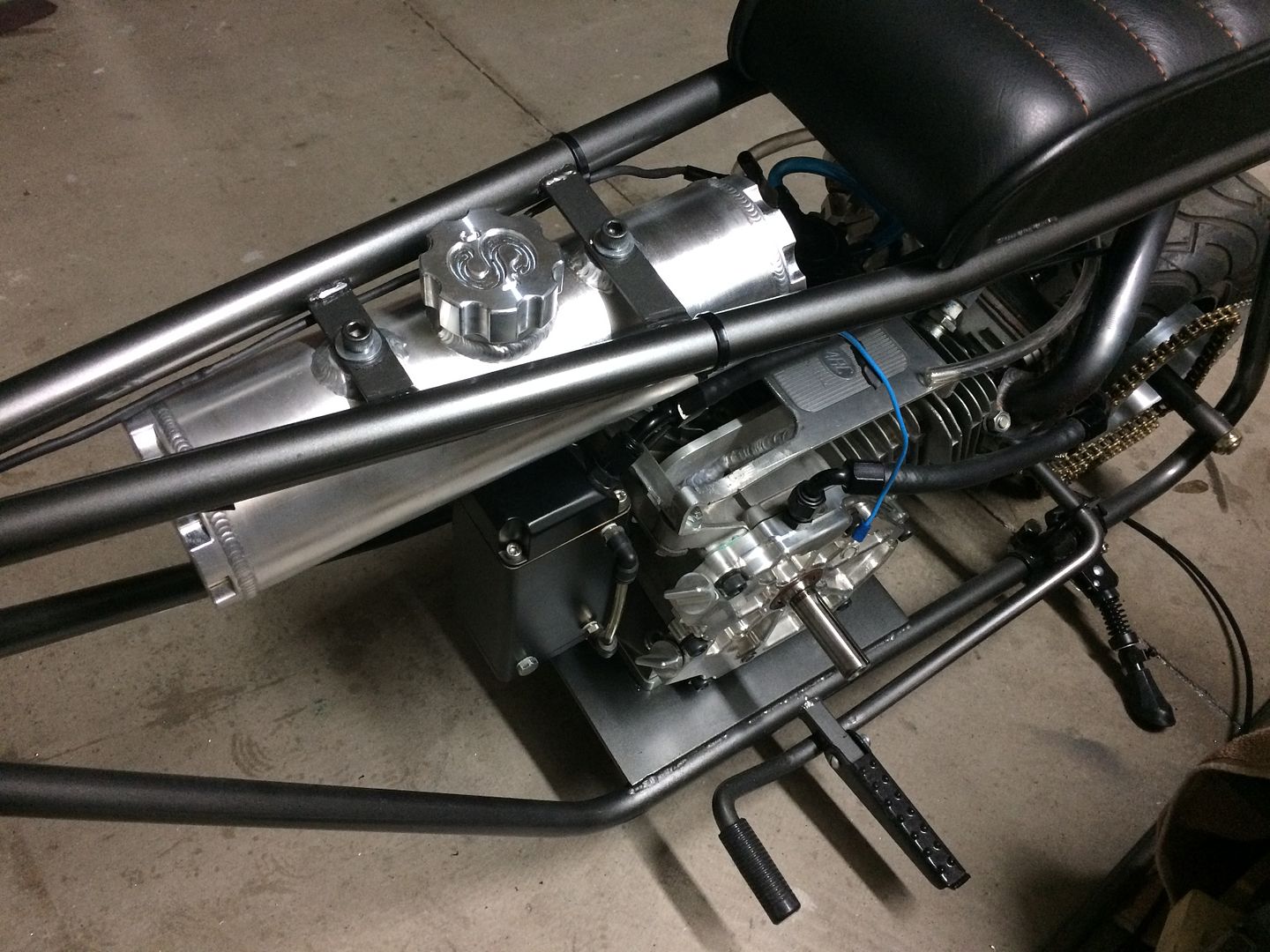

I've never seen anyone ask, but being that it has silicon in it like 4043, the end result would likely be the same. The reason 5356 doesn't turn black is because it has magnesium as the alloying element vs silicon.Jakedaawg wrote:What you are doing is really cool. I see you mentioned using the 4943, do you know if it can be anodized?

Return to “Welding Projects - Welding project Ideas - Welding project plans”