To be honest I'm not 100% sure, we blew up 2 torches and they called our local Miller repair center to come out and look at it. I did pull the lines to check flow which we were getting, but it would fault out with a flow fault. I purged and primed it a few times but it would constantly fault. I know they replaced a filter and a relay but the problem still existed. Then I heard after a second service call that the cooler was dead, in repairable and a external cooler was on the way. I was expecting a Cool mate 3 that would bolt into the bottom.....I came back from a vacation day and saw the big ole Coolmate 4 sitting beside it. I also can't believe it couldn't be fixed, I may call down and get the scoop from the repair center.dunkster wrote:Rick

What went wrong in the cooler? I've had mine apart several times for pump rebuilds....trying to wrap my head around what could've gone bad requiring a new unit. This was the tigrunner, correct?

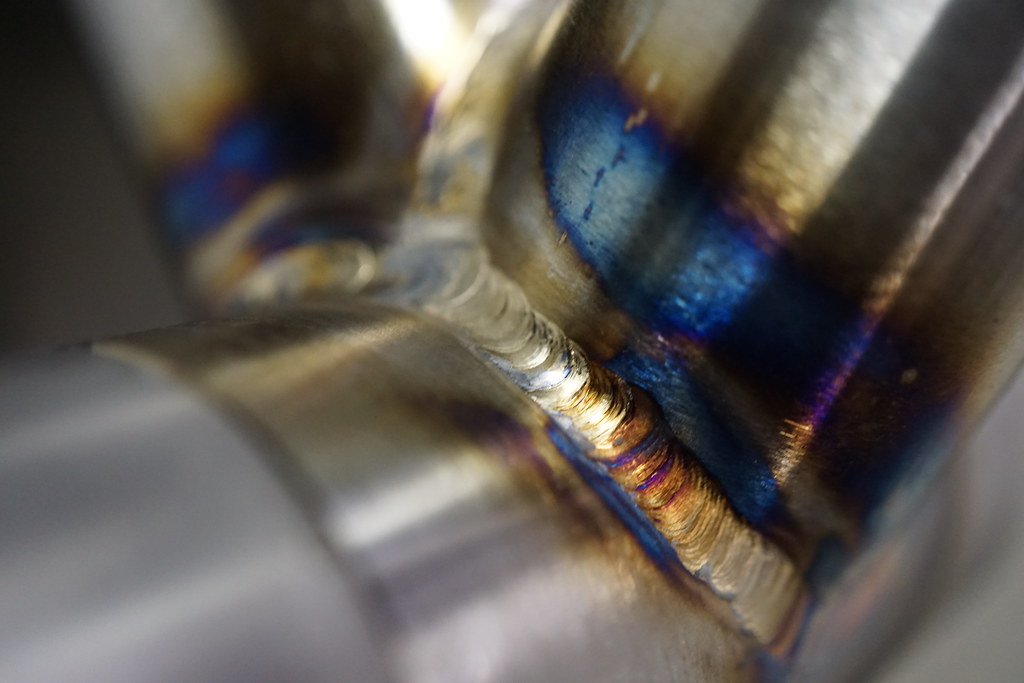

So since I'm known for my fab work they asked me if I could make a shelf for it to keep it off the floor....I decided to build the cart and keep it all contained and the same width so the cables and torch doesn't get damaged, I think I'm the only one at my work that truly cares about maintaining the welders and treat them like my own.