I see the EVOSAW380 on Amazon for $409 and the RAGE2 for $187.

Both have a 1800 watt 15 amp motor and 1450 rpm

Both use the 14" blade

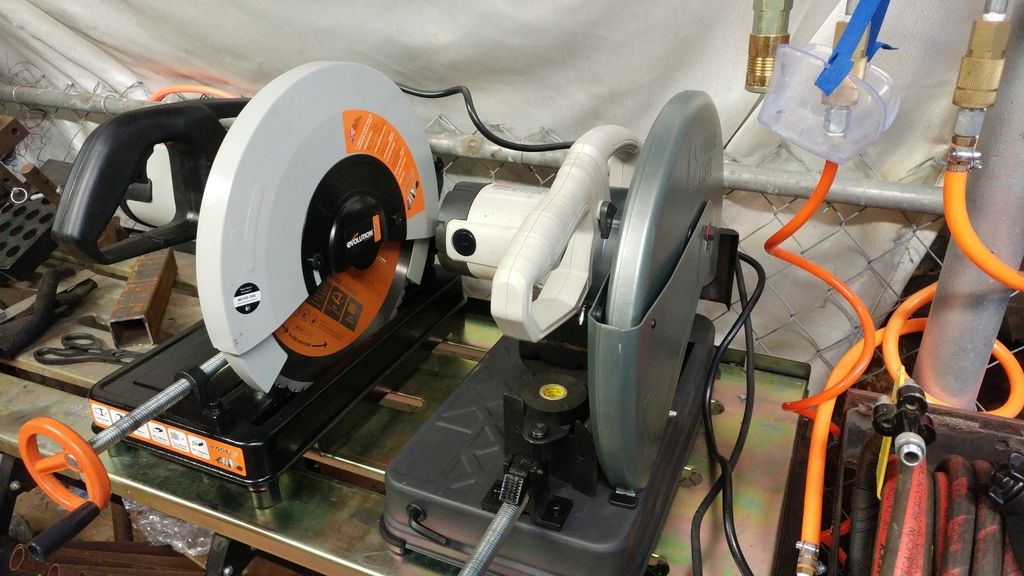

Both seem to use the same base, at least by looking at the photo

I can't find the RAGE2 on the Evolution website

Anyone have either of these would like more info.

Metal cutting - oxyfuel cutting, plasma cutting, machining, grinding, and other preparatory work.

I've got the Rage2

http://www.evolutionpowertools.com/uk/build/rage2.php

Main difference is the blade, Rage 2 comes with the multipurpose blade and the 380 with the steel blade. Both will fit each machine.

The 380 has a quick release that isnt on my Rage (might have now, mine is an early one serial no 30-ish)

Looks like the base is cast on the 380. I have a cast base too but they changed that to pressed, flimsy, plate on later models.

If they done good they went back to cast on the Rage too. Now about people returning them after found them flexing too much.

The clamping is crap on 45 degree mitre, need additional clamping not to move while cutting

http://www.evolutionpowertools.com/uk/build/rage2.php

Main difference is the blade, Rage 2 comes with the multipurpose blade and the 380 with the steel blade. Both will fit each machine.

The 380 has a quick release that isnt on my Rage (might have now, mine is an early one serial no 30-ish)

Looks like the base is cast on the 380. I have a cast base too but they changed that to pressed, flimsy, plate on later models.

If they done good they went back to cast on the Rage too. Now about people returning them after found them flexing too much.

The clamping is crap on 45 degree mitre, need additional clamping not to move while cutting

Pictures from my scrap collection:

http://forum.weldingtipsandtricks.com/v ... f=9&t=5677

http://forum.weldingtipsandtricks.com/v ... f=9&t=5677

noddybrian

- noddybrian

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 24, 2013 12:13 pm

The Rage range is really for cutting wood but will also cut most materials with the same multi purpose blade - just not that much if it's steel- we had them at a sign place I did work for & I got a couple for odd job site work - mostly cut aluminum in various sections - sometimes plastics depending on the sign - worked well for that but I would not try doing steel all the time - they are not built for it despite similar motors on paper - gearboxes & various other parts are different - that's why there is a marked jump in price between Rage & the dedicated metal cutting models - also with all the carbide tip saws be aware even a slight hard spot in the metal from imported steel will kill the blade & they are quite expensive - in my opinion a bandsaw is far more useful.

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities