We have previously used poly barrels for fuel on the rivers, but these are known to crack.

Will be building gas tanks- a large bow tank- about 100 gallons, and 2 saddle tanks about 40 gallons each. I was planning on using 3/16 aluminum for all, because that's what my mentor recommends, but it seems heavy for the smaller ones. Any thoughts? The large one will have internal baffles.

Thanks

Tig welding tips, questions, equipment, applications, instructions, techniques, tig welding machines, troubleshooting tig welding process

noddybrian

- noddybrian

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 24, 2013 12:13 pm

Of the aluminum boat tanks I've repaired or added fittings to they have all been 1/8" or 3mm - including factory installed ones - unless this is some sort of race boat subject to extreme shock / vibration loadings I think going to 3/16" is overkill & just ups the weight & cost.

If your very limited on size / shape I'd go ahead & make them - but a trip to a commercial vehicle breaker / salvage yard often yields a good variety of aluminum truck fuel tanks in various sizes / shapes - all complete with fuel take off - fill point & level sender - & their made of a suitable alloy & certified ( maybe not for marine ) - worth checking if for your boat the tanks need any sort of test - in the UK most fuel tanks do even on cars & boats except the smallest of pleasure craft do.

Good luck with you project.

If your very limited on size / shape I'd go ahead & make them - but a trip to a commercial vehicle breaker / salvage yard often yields a good variety of aluminum truck fuel tanks in various sizes / shapes - all complete with fuel take off - fill point & level sender - & their made of a suitable alloy & certified ( maybe not for marine ) - worth checking if for your boat the tanks need any sort of test - in the UK most fuel tanks do even on cars & boats except the smallest of pleasure craft do.

Good luck with you project.

Thanks Noddybrian

Unfortunately, the tanks need to be custom due to size/geometry constraints. These are flat bottom boats that go on 1000+ mile trips that involve a fair amount of pounding. Weight does become an issue though. I will err on the side of safety if in doubt, but looking for perspective. My commercially built 160 gallon tank isn't 3/16th either.

My access to salvage is limited

Unfortunately, the tanks need to be custom due to size/geometry constraints. These are flat bottom boats that go on 1000+ mile trips that involve a fair amount of pounding. Weight does become an issue though. I will err on the side of safety if in doubt, but looking for perspective. My commercially built 160 gallon tank isn't 3/16th either.

My access to salvage is limited

- Otto Nobedder

-

Weldmonger

-

Posts:

-

Joined:Thu Jan 06, 2011 11:40 pm

-

Location:Near New Orleans

Since gasoline and diesel both weigh about 6 lb/gallon, That exra 1/16 of aluminum is not a significant weight penalty as a percentage of "full" weight. The saddle tanks will hold 240 lb. each. If they're relatively tall (taller than wide), you may want the extra thickness in the absence of baffles (the abuse a marine tank sees is mostly pounding along the vertical axis).

Or, to use 1/8", you might consider adding baffles as cross-tank reinforcement for 1/8" material, but that may be almost a break-even on weight with extra labor.

How the tanks are mounted has an influence, as well. If they are bedded in fiberglass or urethane foam, so they are supported on all sides rather than retained by a few straps, there's a designed-in extra strength.

As for alloys, I'd think 5053 would be a good compromise between stength, ductility, and corrosion resistance.

There ARE a few marine specialists here, and I'll defer to their judgement on that matter.

Steve S

Or, to use 1/8", you might consider adding baffles as cross-tank reinforcement for 1/8" material, but that may be almost a break-even on weight with extra labor.

How the tanks are mounted has an influence, as well. If they are bedded in fiberglass or urethane foam, so they are supported on all sides rather than retained by a few straps, there's a designed-in extra strength.

As for alloys, I'd think 5053 would be a good compromise between stength, ductility, and corrosion resistance.

There ARE a few marine specialists here, and I'll defer to their judgement on that matter.

Steve S

11 gauge is the standard fare for even high performance offshore boats. I have even built diesel tanks upwards of 300 gallons of it. Never seen the material itself fail, but improper welding with regard to outside corner fit up and penetration.

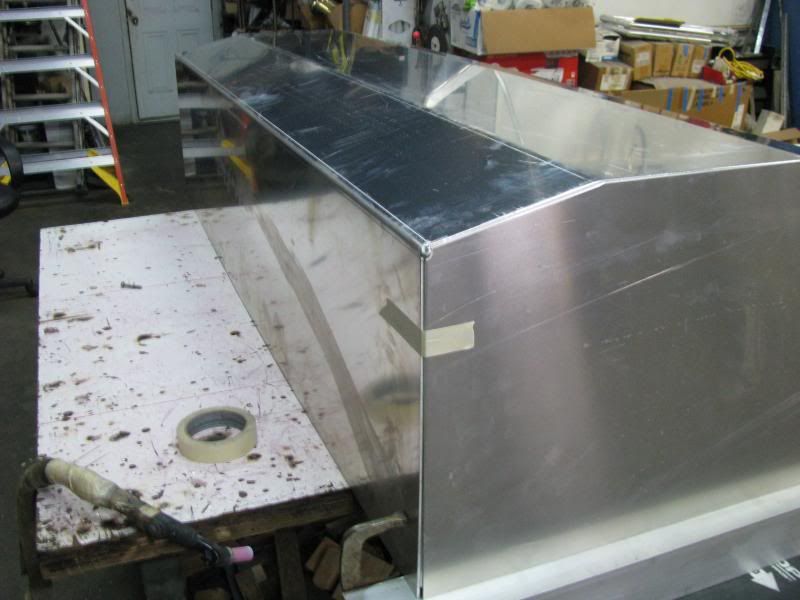

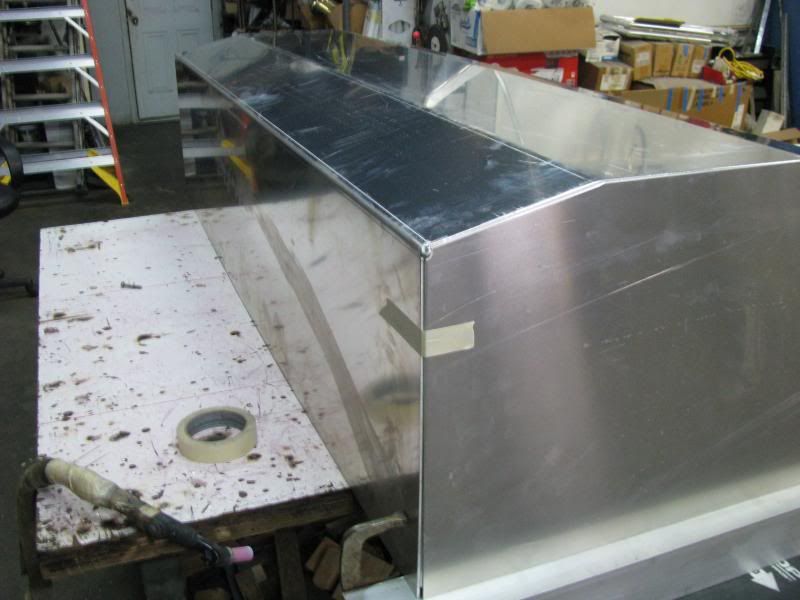

This is a 70 something (guessing, it may be more and don't feel like doing the math) gallon with two baffles. It's a belly tank of 5052 11 gauge if I recall correctly. It was a rush job so I had no casual care of all the details other than. . ."weld this." Also, if you are going to be tig welding the baffles in, you may want to weld right angle flanges on the baffles or get them broke that way because TIG will highly distort 11 gauge welding inside corners. Otherwise, a spool gun would be your best bet for the baffles.

This is a 70 something (guessing, it may be more and don't feel like doing the math) gallon with two baffles. It's a belly tank of 5052 11 gauge if I recall correctly. It was a rush job so I had no casual care of all the details other than. . ."weld this." Also, if you are going to be tig welding the baffles in, you may want to weld right angle flanges on the baffles or get them broke that way because TIG will highly distort 11 gauge welding inside corners. Otherwise, a spool gun would be your best bet for the baffles.

Miller ABP 330, Syncrowave 250, Dynasty 300 DX.

Honorary member of the Fraternity of Faded Tee Shirts.

Honorary member of the Fraternity of Faded Tee Shirts.

Return to “Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding”

Jump to

- Introductions & How to Use the Forum

- ↳ Welcome!

- ↳ Member Introductions

- ↳ How to Use the Forum

- ↳ Moderator Applications

- Welding Discussion

- ↳ Metal Cutting

- ↳ Tig Welding - Tig Welding Aluminum - Tig Welding Techniques - Aluminum Tig Welding

- ↳ Mig and Flux Core - gas metal arc welding & flux cored arc welding

- ↳ Stick Welding/Arc Welding - Shielded Metal Arc Welding

- ↳ Welding Forum General Shop Talk

- ↳ Welding Certification - Stick/Arc Welding, Tig Welding, Mig Welding Certification tests - Welding Tests of all kinds

- ↳ Welding Projects - Welding project Ideas - Welding project plans

- ↳ Product Reviews

- ↳ Fuel Gas Heating

- Welding Tips & Tricks

- ↳ Video Discussion

- ↳ Wish List

- Announcements & Feedback

- ↳ Forum News

- ↳ Suggestions, Feedback and Support

- Welding Marketplace

- ↳ Welding Jobs - Industrial Welding Jobs - Pipe Welding Jobs - Tig Welding Jobs

- ↳ Classifieds - Buy, Sell, Trade Used Welding Equipment

- Welding Resources

- ↳ Tradeshows, Seminars and Events

- ↳ The Welding Library

- ↳ Education Opportunities